Big Data:

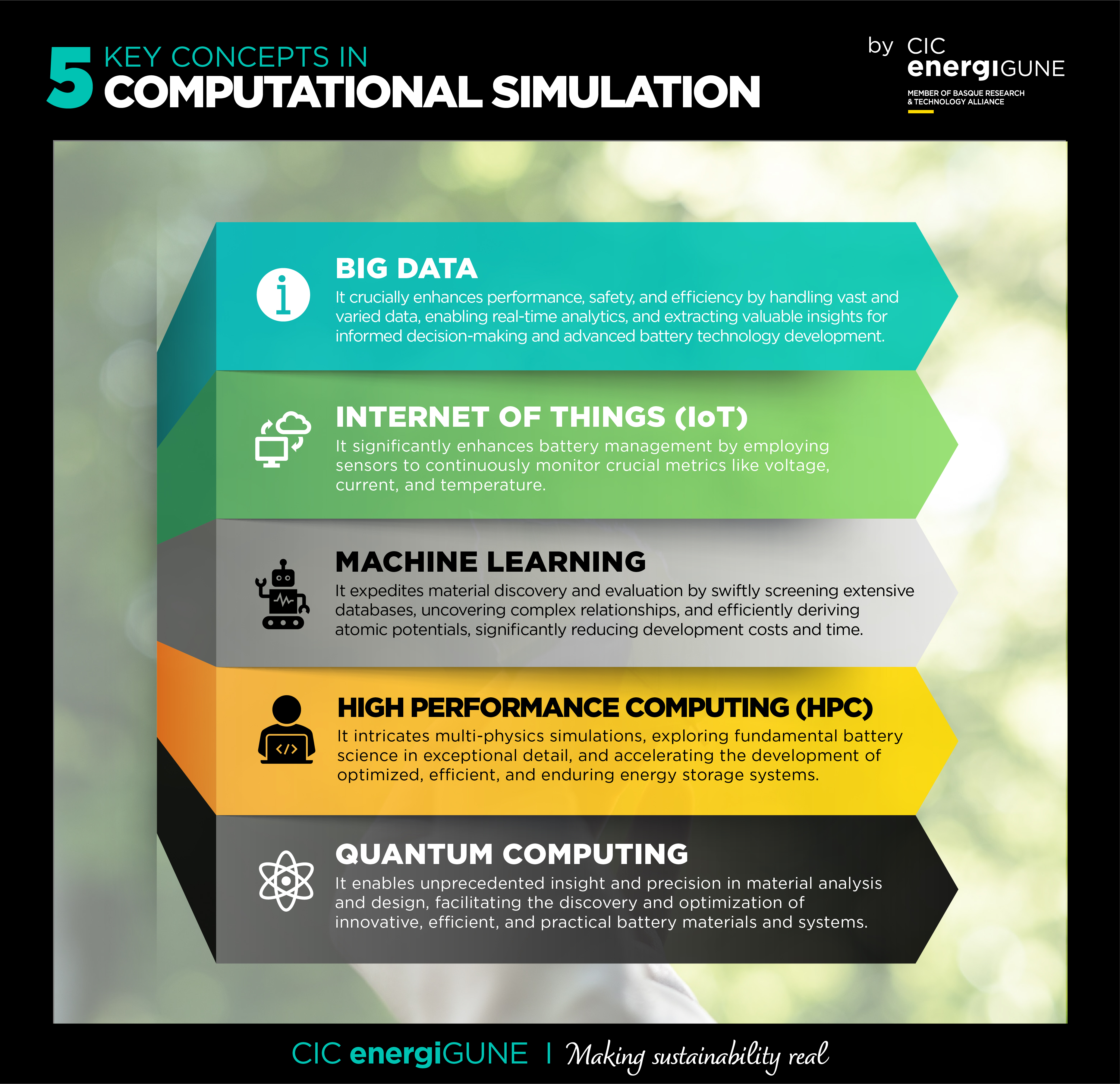

Big Data, a term widely recognized across various industries, has now made its presence felt in battery engineering. To appreciate its significance, it is essential to consider Big Data through the lens of the five V´s:

- Volume: Big Data encompasses datasets of vast size, ranging from Terabytes (1 TB equals 1,000 Gigabytes) to even Pettabytes (1 PB equals 1,000 Terabytes).

- Variety: Having a high volume of data is challenging enough, but having variety within that data increases complexity. Battery data exhibits a range of variables depending on the application, from current, voltage, and power in home storage systems to velocity, requested power, voltage, and current in electric buses. Furthermore, data resolution can vary significantly, with home storage systems offering data at 1–5-minute intervals, while electric vehicle (EV) applications demand data at the 1-second level or even less.

- Velocity: In battery research, speed is of the essence. Real-time or near-real-time analytics have become crucial; particularly, battery safety algorithms have become more computationally intensive, in order to maintain velocity and prevent critical failures.

- Value: it is the underlying reason for tackling all other technical challenges Big Data brings with it. After all, having data is worthless if it cannot be used to generate value. Value is created in the battery industry by analyzing collected data to reduce safety risks and related costs, inform battery supply chain decisions, and extend battery lifetimes.

- Veracity: Ensuring data accuracy and validity is paramount, but this is often challenging due to the sheer volume and variety of data. An outlier voltage reading in one system might be the norm in another.

Nowadays, there are available different databases that provides many materials structure information. Some of them are experimentals, such as the Inorganic Cristal Structure Database (ICSD), and other theoretical, such as the Material Project (MP). But the general-purpose database usually cannot meet the special needs of battery materials. For the development of battery materials, it is necessary to consider specific properties such as energy density, ion transport properties, charge and discharge rates, and so on.

In the battery space, data volume is generated by the battery management systems (BMS). The volume of data generated by a single BMS is small and doesn’t fit into the scope of Big Data. However, when we start collecting historic BMS data, we easily get into the Terabyte range of data volume.

Internet of things (IoT):

Today, the use of sensors connected to devices that measure various magnitudes has become commonplace. In the context of energy storage, Battery Management Systems (BMS) serve as a prime example of IoT integration.

In the domain of batteries, these sensors measure crucial performance metrics such as voltage, current, and temperature. Continuous monitoring and supervision of these metrics are facilitated through software, and battery state predictions, including State of Charge (SOC), State of Health (SOH), and Remaining Useful Life (RUL), are computed with the assistance of Machine Learning (ML).

One notable deficiency is the absence of alert mechanisms related to the behavior of Lithium-ion Batteries (LiB). Alerts are of great importance in monitoring tasks for batteries, even more when managing complex and sophisticated equipment. For example, if no alert is generated when the temperature increases above a certain value, the battery can have great problems, being necessary to replace.

In the framework of the IoT, the goal is to achieve power autonomy through batteries that can sustainably recharge themselves. For that, it would be interesting to harvest ambient energies such as light, heat and vibration and convert them to electricity. In fact, it has to be taken into account that most devices have an operational life of over 10 years, while the batteries that power them last 2 years or less.

Machine Learning in Battery Research:

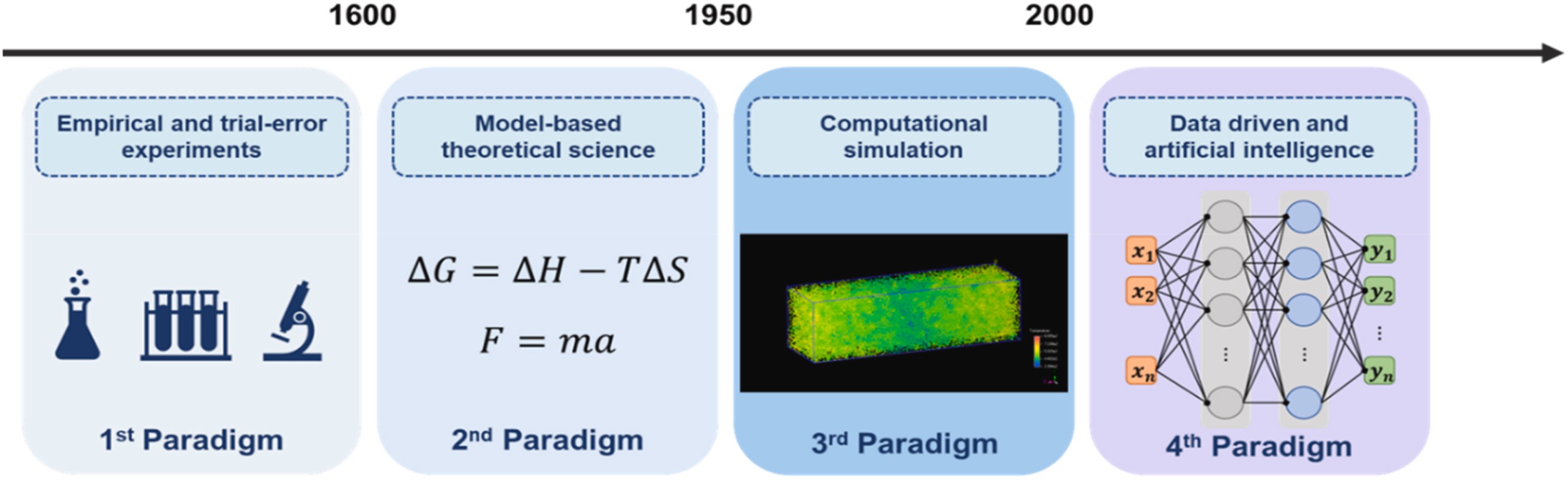

In the realm of battery research, various paradigms have been employed. Traditional trial-and-error experimental methods rely on prior experience and are often time-consuming, costly, and inefficient.

On the other hand, some limitations of the traditional multi-physics-based materials simulations, which are prominent of the model-based theoretical science and computational simulation paradigms, are that the computational simulation methods take less account of the realistic experimental conditions, and that the hypothetical structures may not be thermodynamically stable or even do not exist in practical applications. In addition, the high computational cost and the quantitative errors of the simulations are the main drawbacks of these paradigms.