Within the Advanced cathode research line at CIC energiGUNE, we are involved in several European funded R&D projects i.e. CoFBAT, 3believe, HighSpin, Nextcell where this cathode material is employed. The global aim of all these projects is to bring this cobalt-free cathode material from the laboratory scale to first prototypes that could be used in automotive applications or stationary energy storage.

The use of cobalt in batteries

Cobalt is a key element to produce Li-ion batteries. Today already more than 60% of mined cobalt is destinated for battery cathodes. Additionally, 50-60% of the worldwide cobalt resources are in the politically unstable Congo (DRC) and are extracted by questionable working conditions. In fact, it was identified by the European Commission already in 2017 as a critical raw material. Therefore, cobalt-free Li-ion cathode materials are key for the future generation of Lithium-ion batteries for electric vehicles.

NCM (Nickel Cobalt Manganese oxide) is one of the most employed cathode material, specially in automotive applications, due to its high energy density. The stoichiometry of this material can vary depending on the content of each of the three metals.

In fact, in the last years, the cobalt content has decreased from high cobalt content NCM-111 to lower cobalt content stoichiometries such as NCM-622 and NCM-811. These materials also present very high specific capacities, but, in turn, reduces the cycle life (cobalt provide stability to the structure). Moreover, their synthesis process becomes more complex due to the formation of lithium off-stoichiometric phases. Despite of the mentioned disadvantages, the low amount of cobalt (and subsequently lower cost) have led to the fast commercialization of these cobalt-poor materials.

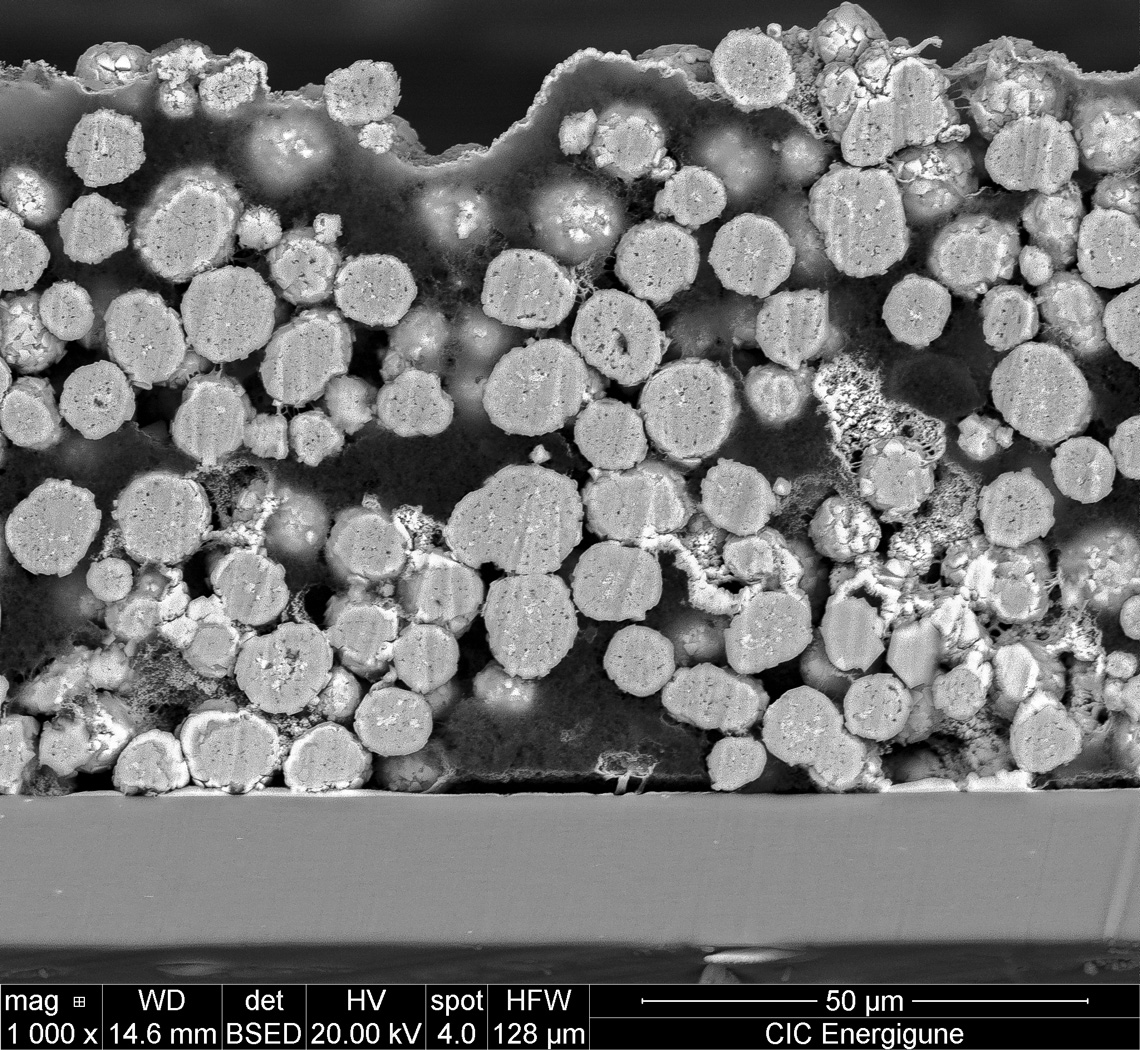

However, new cobalt-free chemistries are even more attractive, as the cost of the cathode material can be reduced by up to 60% (compared to NCM). One of the most mature technologies among the cobalt-free family is the LNMO, as it has several advantages. It presents a long high voltage plateau and very fast lithium insertion and extraction. This means that the battery can be charged/discharged in very short time and can operate at elevate voltage (around 4.7 V), which yields to high energy densities of 650 Wh/kg at cell level (vs the cathode mass).

Electrolytes for high voltage operation

The most challenging aspect for this technology is to find an electrolyte that is stable in the voltage window of this material (3.5 to 4.9 V). In this sense, the research followed by CIC energiGUNE in the last years includes the use of gel polymer electrolytes with the aim of improving the battery safety at these high voltages.

However, one of the major bottlenecks towards commercialization of this battery system is its reduced life cycle compared to commercial lithium-ion batteries. For this reason, thanks to the large variety of characterization facilities available within the CIC energiGUNE platforms, new protocols for diagnosing the degradation of gel-based lithium batteries have been developed. This precise diagnosis has allowed us to improve the processing methods and to develop mitigation strategies that increase the battery lifetime. Today, over 250 cycles have been achieved to 80% SoH (that is considered the end of life (EoL) in automotive applications.

In the newest project HighSpin, we will go a step further on sustainability and greener processes using aqueous-based solvents for the cathodes. Recycling routes for the recovery of the critical material are also envisaged.

In addition to this, the research activities of the Advanced cathode research line also include the understanding of the structural properties and redox activity of the synthetized LNMO material and its relation to the electrochemical properties. Operando x-ray absorption spectroscopy has been employed to elucidate the influence of the transition metal order on the reaction mechanism of the LNMO spinel.

Other techniques like solid-state nuclear magnetic resonance (ssNMR) and neutron powder diffraction (NPD) were also used ex-situ to provide insights on the changes of the lattice parameters and the metal dispositions around the Li site. This fundamental study has revealed an important insight about the dynamics of LNMO’s cycling mechanisms. This will help to develop new strategies for the future LNMO material development.

Due to the unprecedent growth rate on the demand of some battery materials like cobalt, the development of alternatives that can replace the critical materials identified by the EU is one of the major challenges that the battery research is currently facing. LNMO is a promising cobalt-free cathode alternative, and therefore major research efforts focus on its development. CIC energiGUNE is on this path for accelerating its commercialization, bringing greener batteries from the lab to real applications.

Part of the research performed at CIC energiGUNE for the development of LNMO cathode materials has received funding from the European Union’s H2020 research and innovation program under Grant Agreements no. 875033 and 875126, and from the European Union’s Horizon Europe research and innovation program under Grant Agreement no 101069508.