Impact on the entire value chain

Energy storage is growing in Europe. Residential applications represent €1.4 billion per year, and electric vehicle storage systems are expanding, currently estimated at €130 million per year.

Aligned with this huge demand, CoFBAT´s approach covers the entire value chain; from materials development, to cost-effective technology validation (optimized in performance and cost), assembly and cell optimization, to achieve cobalt-free batteries with the following characteristics:

- Longer lifetime (≥10,000 cycles).

- Lower cost (up to 0.03 euros/kWh/cycle)

- Improved safety

- More efficient recycling (>50%).

CoFBAT joins Europe in becoming a competitive player in the global value chain of energy storage systems, which is highly dependent on the materials used in their production.

It is well known that cobalt, commonly used in lithium-ion batteries, is one of the least abundant materials in nature, which results in an increase in its price on the market. In addition, there is a supply risk attached to its extraction, mainly concentrated in the Democratic Republic of Congo.

However, the estimated demand for cobalt in the coming years continues increasing. This provides a clear indication to the scientific community of the need to move towards cobalt-free cathode technologies. Hence the relevance of the research undertaken at CoFBAT as an important step in addressing these issues.

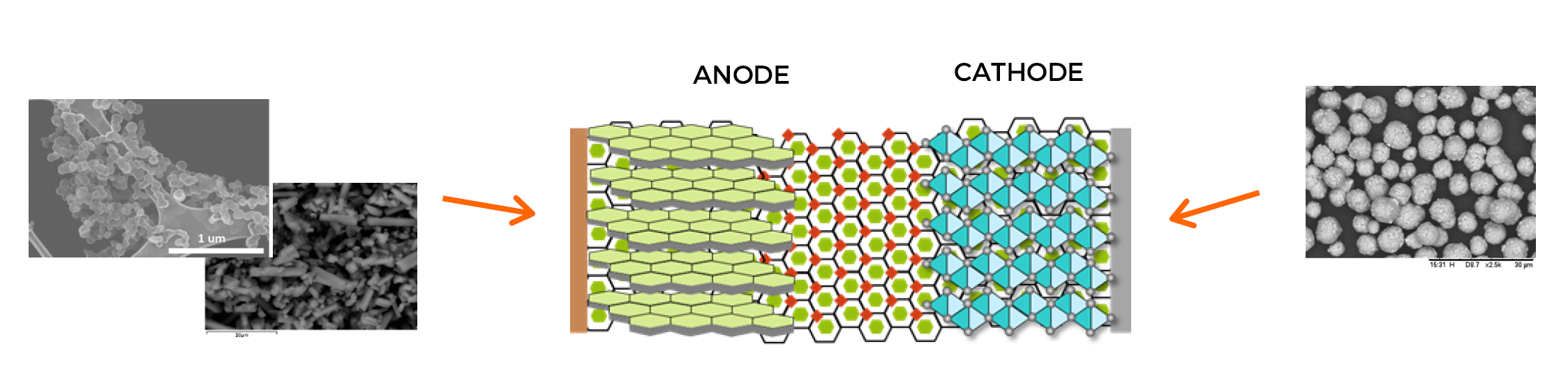

In order to develop advanced materials for environmentally friendly cobalt-free lithium-ion batteries, CoFBAT is studying several formulations, such as spinel cathodes based on LMNO, titanium niobates and silicon-based nanocomposites for the anode and gel electrolyte. These are optimal in terms of safety and stability, although with a lower energy capacity compared to Li-ion batteries that are currently available on the market. Nevertheless, this is balanced out by their high voltage operation and the possibilities of reducing costs, which is of particular interest for stationary applications.

On the other hand, this European project works on the inclusion of a polymer electrolyte in gel that replaces the conventional liquid electrolyte, which is the prelude to the introduction of solid-state electrolyte technology, which increases the safety of the cell by reducing the potential risks of flammability.

To carry out the research, the project proposes the adaptation of the electrode formulation to active materials, in order to achieve greater cyclability. Also, the electrode formulation is studied to optimize the final morphology and porosity for maximizing its performance.