Molten salts are broadly used in industry, even though its corrosion is an important consideration that often limits the full potential of a technology.

In renewable Energy sector, in solar energy applications, particularly concentrated solar power (CSP) systems, molten salts are used as heat transfer fluids and thermal energy storage materials. Understanding and mitigating corrosion is crucial to ensure the longevity and efficiency of these systems, as corrosion can lead to system failures, leaks, and increased maintenance costs.

In Chemical Industry, molten salts are often used in various high-temperature processes, such as in the production of metals and other industrial chemicals. Corrosion resistance is vital for equipment durability and safety in these environments, where aggressive chemical reactions can occur. Proper management of corrosion can enhance productivity and reduce operational costs.

In Nuclear Industry, in nuclear reactors, particularly in advanced designs such as molten salt reactors (MSRs), molten salts can serve as both a coolant and fuel medium. The corrosion behavior of materials in contact with molten salts at high temperatures is critical for the safety, efficiency, and reliability of nuclear systems. Understanding corrosion mechanisms can lead to the development of more robust materials that improve the lifespan and performance of reactors.

Overall, addressing molten salt corrosion is essential for the stability, safety, and economic viability of technologies and systems across these industries. Research and development in this area aim to improve materials used in these applications to resist corrosion, thereby enabling safer and more efficient operations.

Research at CIC energiGUNE

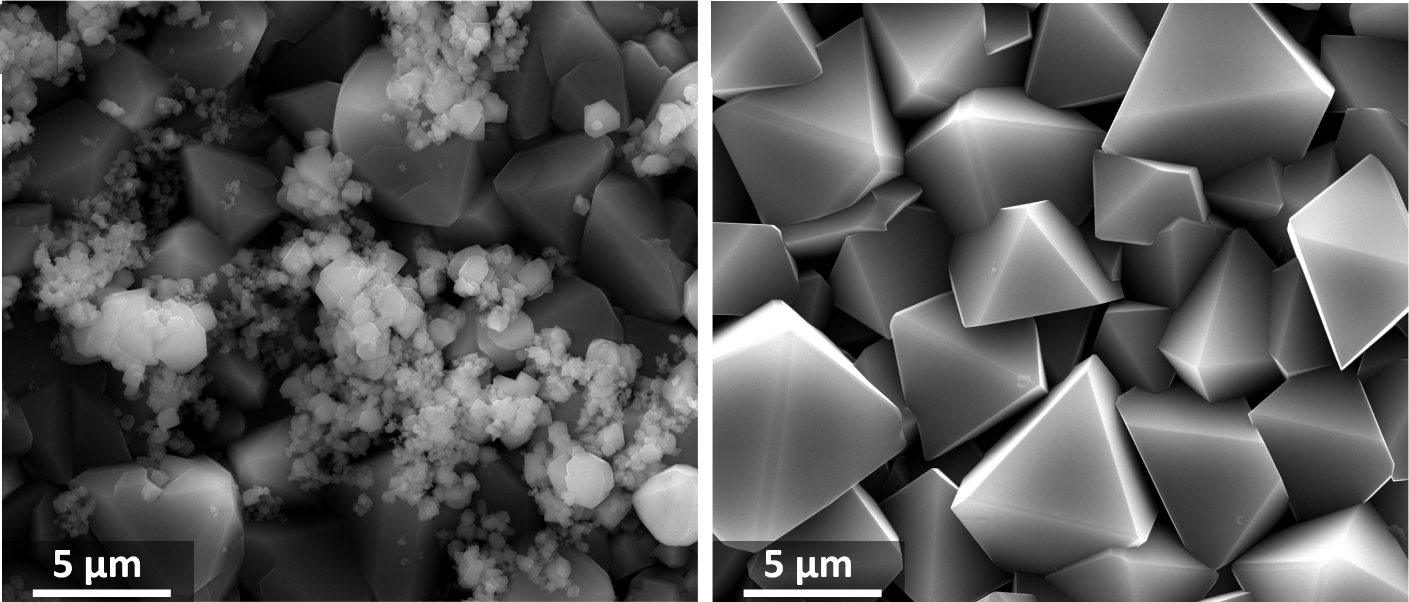

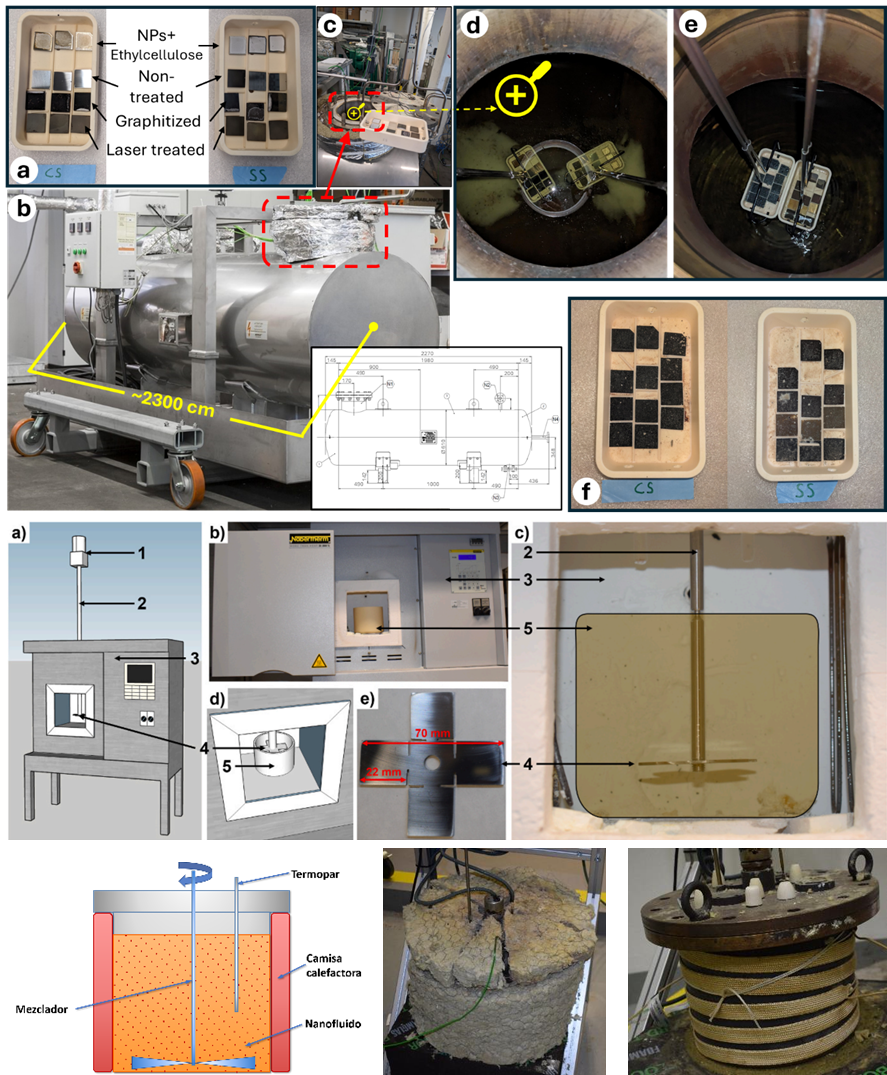

At CIC energiGUNE, the research group Interfacial Phenomena and Porous Media has a rich experience in molten salts corrosion, particularly in the realm of Concentrated Solar Power (CSP) technologies studying corrosion of nitrate and carbonate molten salts and corresponding anti-corrosion measures. Currently, among others, CIC energiGUNE collaborates with Fraunhofer Institute for Solar Energy Systems (ISE) testing at large-scale such corrosion mitigation strategies as Graphitization, Laser texturing and Nanomaterials-based coatings and with the University of the Basque country on the corrosion of molten chlorides.