The prototyping of cells for batteries and supercapacitors is a critical step in advancing the technology, for example, through high voltage cathodes, solid-state batteries, validation of new materials, concepts, manufacturing processes, and battery geometries. In this way, technological development is accelerated by bringing new ideas that are in the state of the art of electrochemical storage to the market.

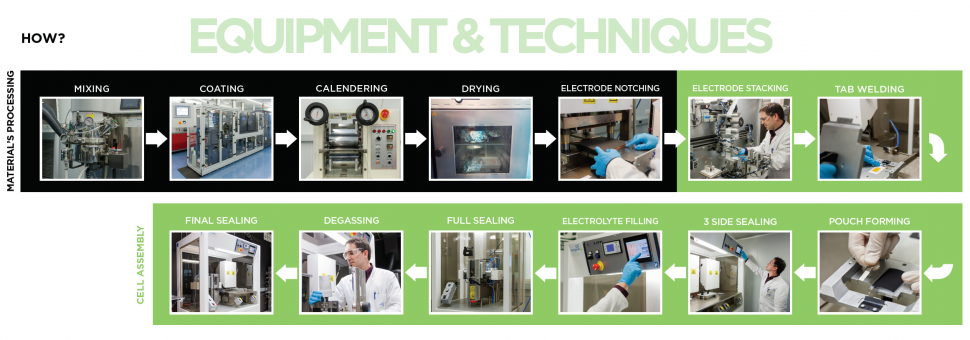

CIC energiGUNE is a European reference center with one of the best prototyping lines in Europe. CIC energiGUNE´s cell manufacturing line allows complete validation of the materials and manufacturing processes of different cell technologies: pouch, cylindrical, flexible, semi-flexible. The center is also a leader in the manufacture of solid-state batteries, promoting the arrival on the market of this technology, which is so essential for electromobility.

One of the differential aspects of this line of prototyping cells is that it has the entire manufacturing process of batteries and capacitors in a dry room environment with minimum humidity. This feature of the room can be used on-demand and allows working with any current or future technology: sodium-ion (Na-ion), lithium-ion (Li-ion), metal-air, lithium-sulfur (LiS), etc. Additionally, this service can scale cathode, anode, and electrolyte materials in quantities necessary for the industrial pre-prototyping of electrochemical cells. Such scaling services can also be offered for solid state batteries.

This platform also allows the validation of materials and manufacturing processes developed by the industry and the characterization of the results through one of the best characterization platforms and experts in Europe.

If you want to know the latest trends in energy storage and new developments in research, subscribe.

If you want to join a top-level team, collaborate with specialists in multiple disciplines or tell us about your concerns, don't think twice...