AITOR VILLAVERDE OREJON

GROUP LEADER

GROUP LEADER

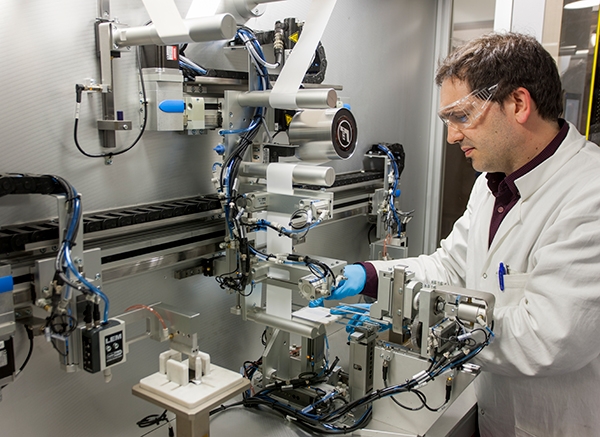

The Dry Room where the cell prototyping line is installed, provides an ultra-dry environment required to handle some novel materials and technologies allowing the processing and assemblying of energy storage devices close to the industrial processes. Dry room provides a safe environment that allows to work with alkaline metals such as lithium or sodium metal and any other moisture sensitive material which are called to lead the coming future of the energy storage. It gives the chance to face and understand the processability problems and therefore provides information for further tuning of the materials improving their performance, developing the technology and reducing technological risks providing competitiveness of the companies.

The platform has the capability to scale up materials from gr to kg per batch, slurry formulation up to 5 liters, double side electrode coating in a roll to roll system in continuous or pattern coatings up to 225mm wide, solid electrolyte membrane extrusion and monolayer or multilayer pouch cell assembly both for liquid and solid electrolyte.

The main characteristics of the platform are:

Every parameter is monitored with a SCADA system, from the air generation system, air flow, recirculation, room parameters, ensuring a safe and comfortable environment to the researches.

CIC Energigune usually works with a pouch cell with 41x60 mm geometry although tools could be changed in order to manufacture bigger cells under request. Monolayer pouch cell can be prototyped for preliminary data and for bigger capacities, multiple layer pouch cell with a maximum thickness of 5mm.

The open platform concept, allows the cooperation with universities, other centers or private companies while retaining the confidentiality.

Brand: PRIMIX [JAPAN]

Model: HIVIS DISPER MIX Model 3D-5

Use: Electrode slurry preparation (anode and cathode). Wide variety of uses from mixing of dry powder particle materials to kneading of high viscosity material

Main Characteristics:

Use: Slurry deposition on current collector and solvents drying.

Characteristics:

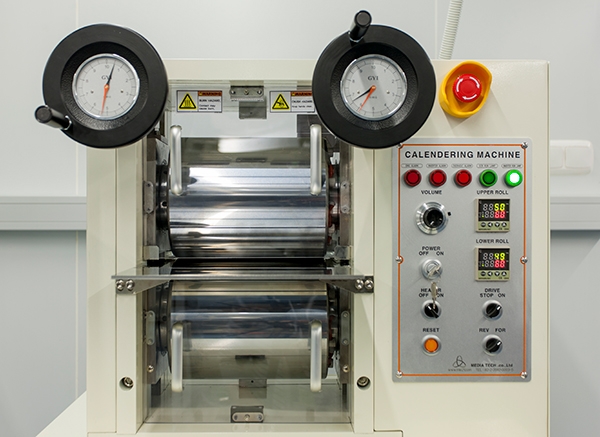

Use: calender the coated electrodes

Main Characteristics:

Use: Electrode cutting to the final geometry

Main Characteristics:

Use: Anodes and cathodes stacking in the desired number of layers interposing a separator in a zig-zag way.

Characteristics:

Use: Contact welding to the electrodes by ultrasonic

Characteristics:

Use: Side sealing and tab sealing

Characteristics:

Use: fill the pouch with electrolyte and seal

Characteristics:

If you want to know the latest trends in energy storage and new developments in research, subscribe.

If you want to join a top-level team, collaborate with specialists in multiple disciplines or tell us about your concerns, don't think twice...