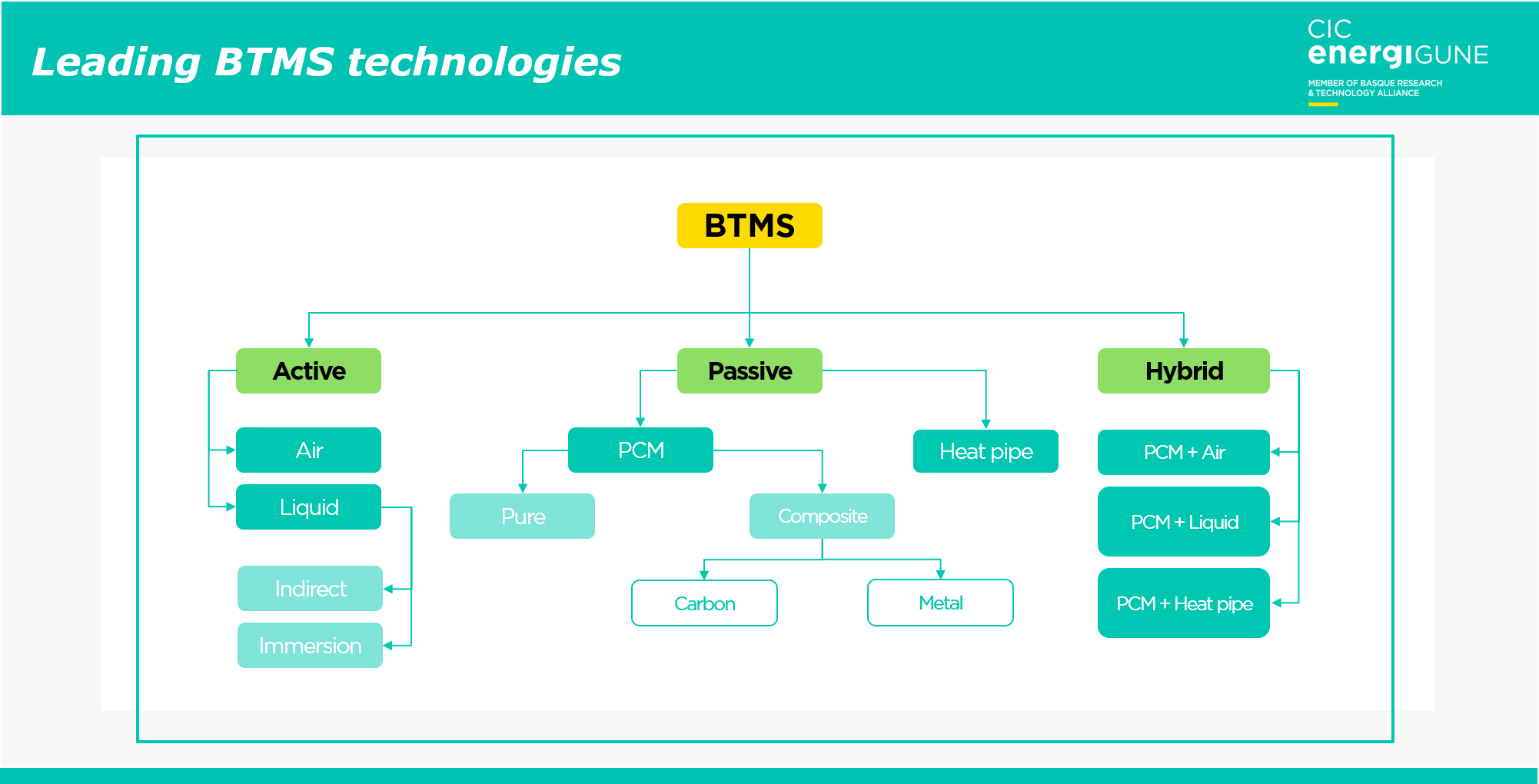

Passive BTMS

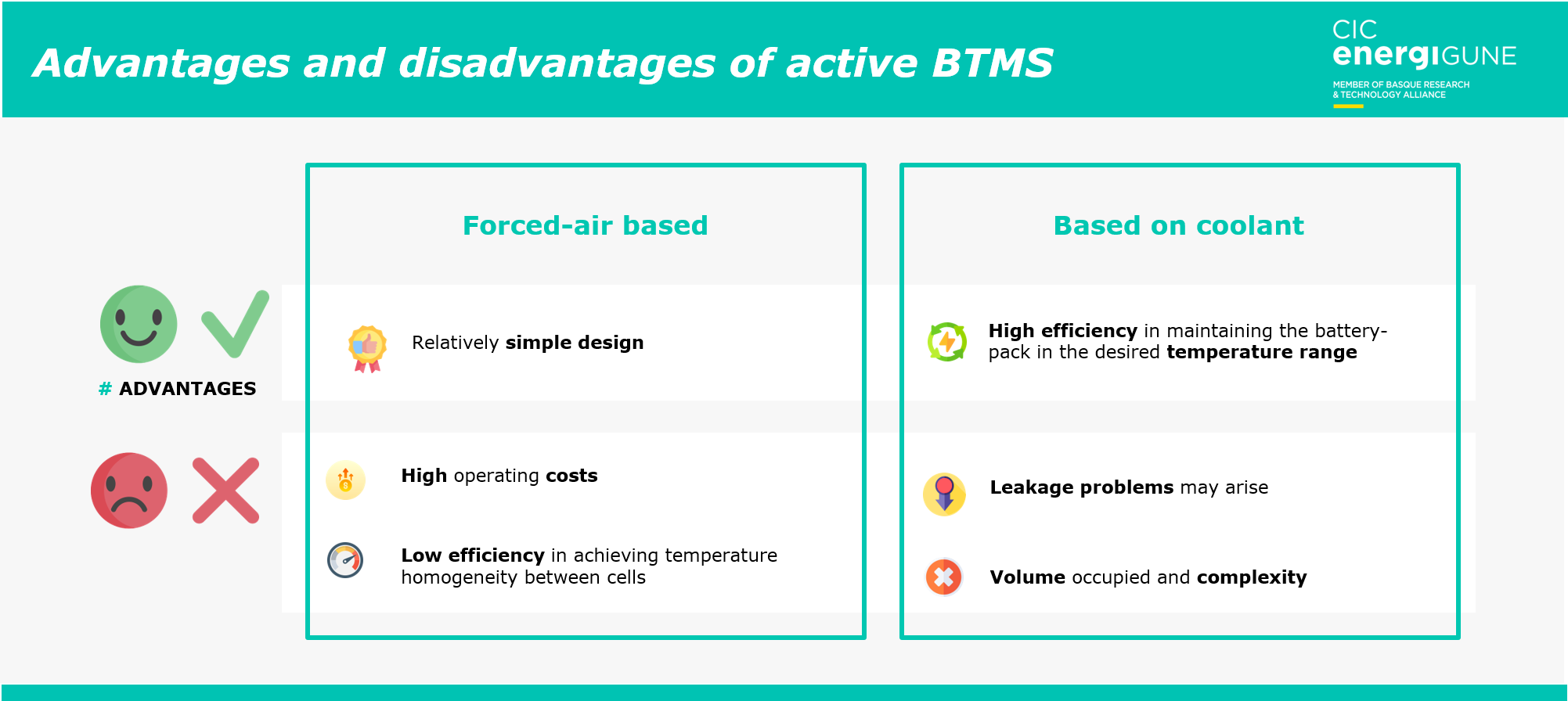

Passive systems are an alternative to active BTMS that overcome their disadvantages. Although these types of systems are not currently implemented in electric vehicles, they have recently become very important due to their operational advantages.

Two large families stand out among the different passive solutions: phase change materials (PCMs) and heat pipes (HPs).

PCMs -especially those with a solid-liquid phase change- have been extensively studied for their application in BTMS. The interest of these materials lies in the possibility of exploring the high energies associated with phase changes (typically >150 J/g) that occur at a nearly constant temperature. These two characteristics make them attractive when maintaining a homogeneous temperature throughout the battery-pack, close to the phase change temperature of the implemented PCM.

The most studied compounds for these applications are paraffins, fatty acids or hydrated salts. Generally, these compounds/mixtures have melting points in the range of 30-50 ºC, making them ideal for battery thermal management.

However, in general, the aforementioned families of PCMs have a relatively low thermal conductivity, a feature that limits heat transfer from the cells to the PCM itself and from the PCM to the battery-pack exterior.

To address this limitation, numerous works in the literature propose embedding the PCM in porous structures (generally metallic), doping the PCM with nanoparticles, fibers or expanded graphite, among others.

Despite their good performance in achieving good thermal homogeneity in the battery pack, PCMs have certain limitations that make them not the preferred option today. These include the following:

- Low thermal conductivity.

- When PCM is doped, it loses energy density.

- Limited thermal storage capacity.

- Increases the weight of the battery-pack.

A second alternative to active systems are heat pipes. These are fluid-filled vacuum tubes (usually with water) that operate by using the vapor-liquid phase change of the fluid.

In general, a heat pipe is composed of three sections: an evaporator (area in contact with the hot source/cell), an adiabatic section through which the vapor circulates, and a condenser (area in contact with the cold source/outside of the battery pack). And, although they are not currently used in battery-packs, their use in the cooling of electronic components is very widespread.

The main characteristics that make them of great interest for implementation in BTMS are their flexible geometry, high thermal conductivity (nearly twice that of solid conductors) and virtually zero maintenance. On the other hand, the main limitations of this technology are its complexity and the cost of the complete solution.

Hybrid BTMS

Finally, in order to take advantage of the benefits of active and passive systems, hybrid systems have emerged, combining two or more of the alternatives described above.

The most studied combinations include the use of PCMs with forced air, PCMs with liquid cooling or PCMs with heat pipes. In the first case, the objective is to achieve a good temperature distribution in the battery-pack and the use of forced air or liquid cooling to evacuate the heat generated to the outside.

In the case of PCMs with heat pipes, the aim is to improve the heat transfer from the PCM to the outside of the cells, so that the cells can be cooled by natural convection.

Although these BTMS systems show a much more effective performance than pure passive or active systems in thermally managing the battery pack, their complexity and cost are a limiting factor for implementation in electric vehicles.

A sector with high expectations

Whichever alternative finally dominates the market in the coming years, what does seem certain is the significance that this sector will gain in the short and medium-term. Not only because of the gradual implementation of electric vehicles, but also because of its usefulness and application in other uses and sectors where the optimum operation and temperature of cells and batteries is critical for their correct operation.

Not surprisingly, if we focus only on the expected market prospects for the BTMS industry associated with electric vehicles, we note that this activity is estimated to reach a value of 12-13 billion euros only until 2024, with a CAGR of almost 40% in the coming years (considerably above the average of other industries).

This only reaffirms the big bets that companies such as Samsung, CATL or LG Chem have started to make on these technologies, demonstrating the future and potential that these new solutions are expected to have in the coming years.

In this sense, at CIC energiGUNE we are also working on disruptive thermal management alternatives in collaboration with cell manufacturers, whose information will be expanded in future articles.