Challenges and advances in the Carbon Footprint of batteries

The Carbon Footprint is an important component in the environmental assessment of batteries, as it determines the total amount of CO2 emissions generated directly or indirectly during the life cycle, including from the extraction of raw materials to production, use and final disposal.

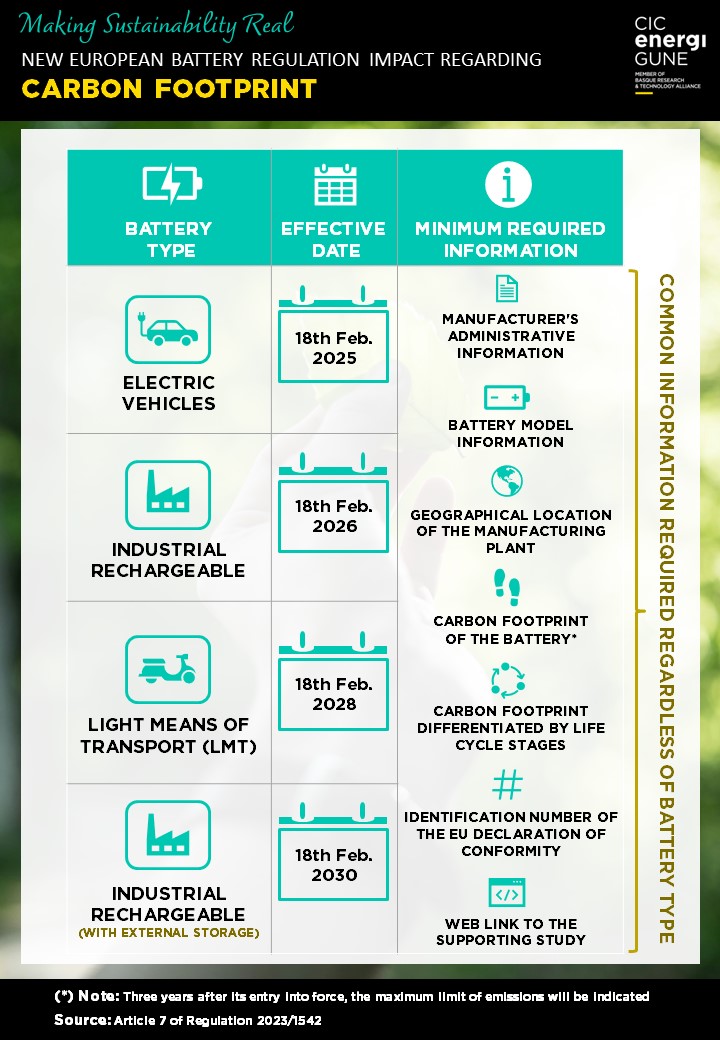

In the context of the Battery Regulation, the document "Rules for the calculation of the Carbon Footprint of Electric Vehicle Batteries", developed by the Joint Research Center (JRC), will be the basis for the application of the requirements established in Article 7 of the Regulation, since, through clear alignments and common framework, it determines the methodology for the calculation and verification of the Carbon Footprint of batteries for electric vehicles.

This document is based on the Environmental Footprint (EF) method developed by the European Commission, as well as on the Product Environmental Footprint Category Rules for Batteries (PEFCR).

Since the publication of the Regulation, it is clear that this is one of the requirements that is generating more interest at national and international level, since manufacturers who want to produce or market their batteries in the European Union, must comply with the declaration of the Carbon Footprint of their product, thus involving an assessment of all stages of production of the product.

This can be complicated due to European dependence on third countries such as China, which not only control the global supply chain for key materials such as lithium, cobalt and graphite, but also perform much of their processing. This presents significant challenges to accurately calculating the carbon emissions associated with battery production, due to the inaccessibility of information. In addition, the complexity of international supply chains requires cooperation and sharing of sensitive (and in most cases confidential) data between multiple actors along the chain.

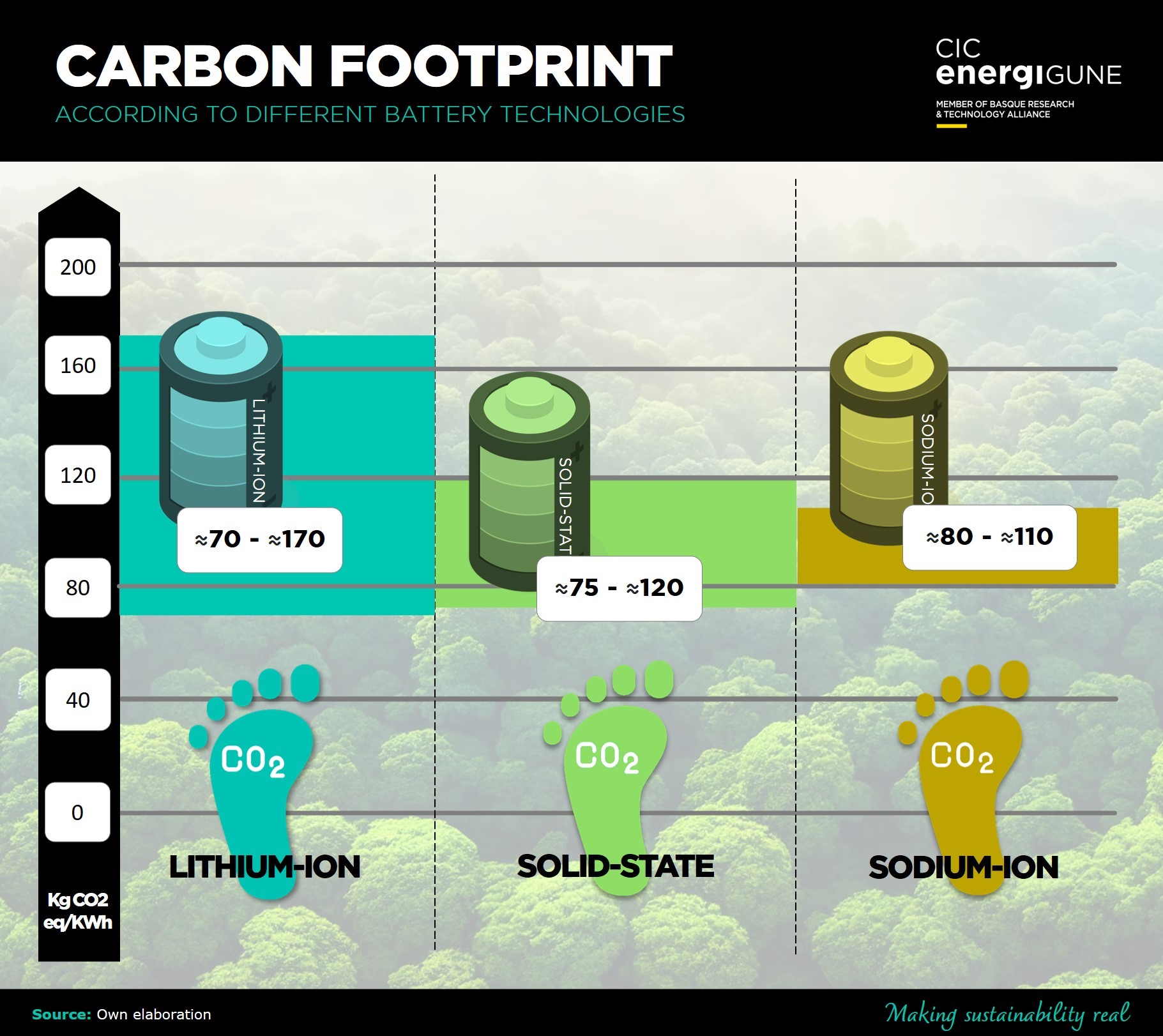

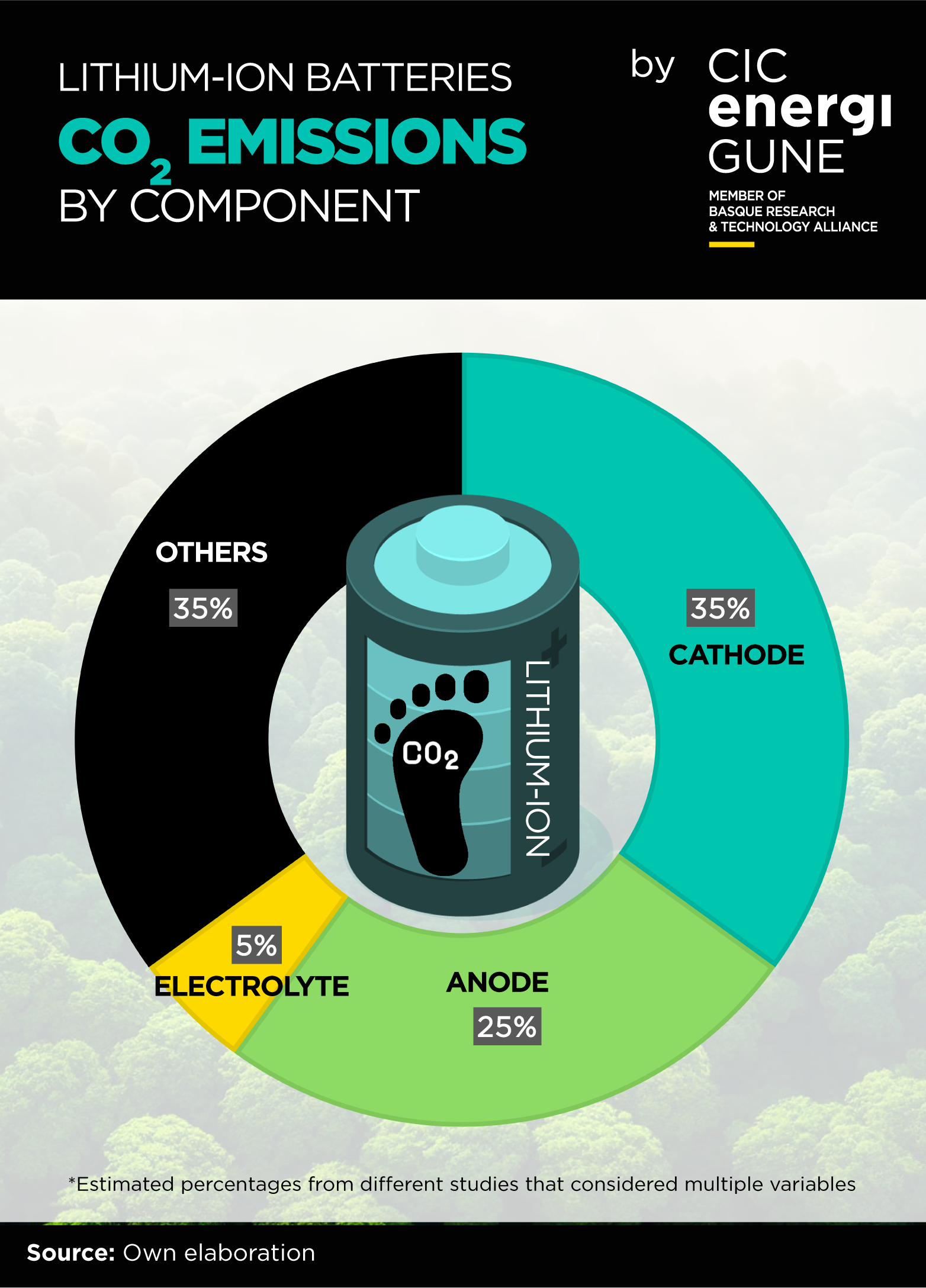

Due to this, during the last years, several efforts have been made to calculate the Carbon Footprint of different battery technologies, mainly lithium ion. This value depends on several factors such as: the type of technology, its application, the manufacturing process, the size, the energy source used during production, the country where it is produced, the stages of the life cycle that have been included, among others. Therefore, emission ranges vary widely, complicating the task of having a single value.