Digital Twins for heat management in electric vehicles

The need of reducing the dependency of fossil fuels and the pollution generated by combustions cars in cities, together with the economic incentives from governments have caused an increment in the interest of the society on acquiring electric vehicles.

Starting from TESLA, almost all historical car manufacturers like BMW, Volkswagen Group, Toyota or Hyundai have introduced in the market electric models at affordable prices.

Even though the electric vehicle has been demonstrated as a mature and reliable technology it still presents an important optimization/improvement potential. Among them, increasing the battery capacity and durability have emerged as the two main targets to boost the electric vehicle.

From CIC energiGUNE we target both aspects. From the Electrochemical Energy Storage area (EES), with the search of disruptive new battery technologies with higher energy densities and better cyclability, and from the Thermal Energy Storage (TES) area in improving its durability by means of ensuring optimal operation conditions.

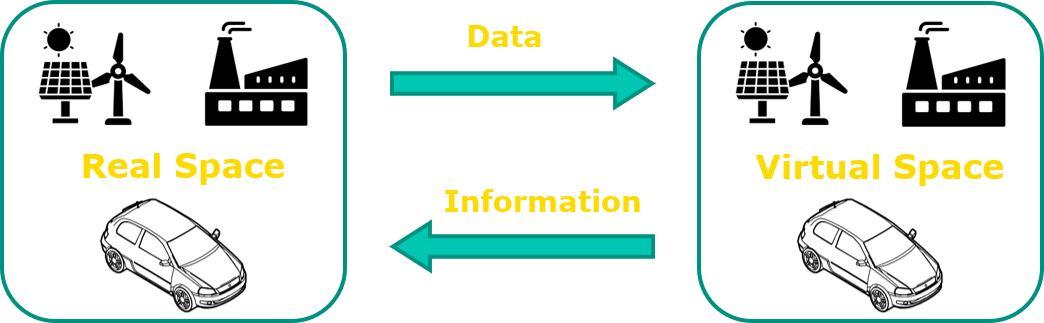

It is in the latter, where a Digital Twin acquires a relevant role. Depending on the battery technology, the operation temperature must be stuck in a certain range. This parameter is critical to avoid both, malfunctioning (sudden discharge) or reduction of the useful life (durability).

While the car is charging or accelerating, batteries suffer from inefficiencies leading to heat generation. If this heat is not properly removed, it may cause temperature rise above the recommended values.

Same undesirable situation occurs if the car is park outside at very low (winter) or high (summer) temperatures. In this frame, a Digital Twin able to take instantaneous decisions over the heat management system as a function of parameters such as ambient temperature, battery temperature, acceleration rate, state of charge, etc. is vital to ensure an efficient performance of the battery, as well as to extend its useful life.

Studies from General Electric (GE) claim that the insights gained from the “Twin” have enabled them to reduce the size of the battery by 16 cells and shave the cost by 15 percent.

Digital Twins for heat management in buildings

Another clear application of Digital Twins is in the area of Domestic Hot Water (DHW) and Heating, Ventilation and Air Cooling (HVAC), not only in residential buildings but also in public ones.

There is not a unique solution to provide DHW and HVAC to a building. For example, old buildings used to incorporate diesel heaters while, newer ones use natural gas or, in the best of the cases biomass.

However, recent regulations for new buildings, together with Government incentives, are making current installed solutions to be a combination of systems based on fossil fuels (mainly natural gas) and renewable energies (solar thermal panels, heat pumps, biomass, etc.).

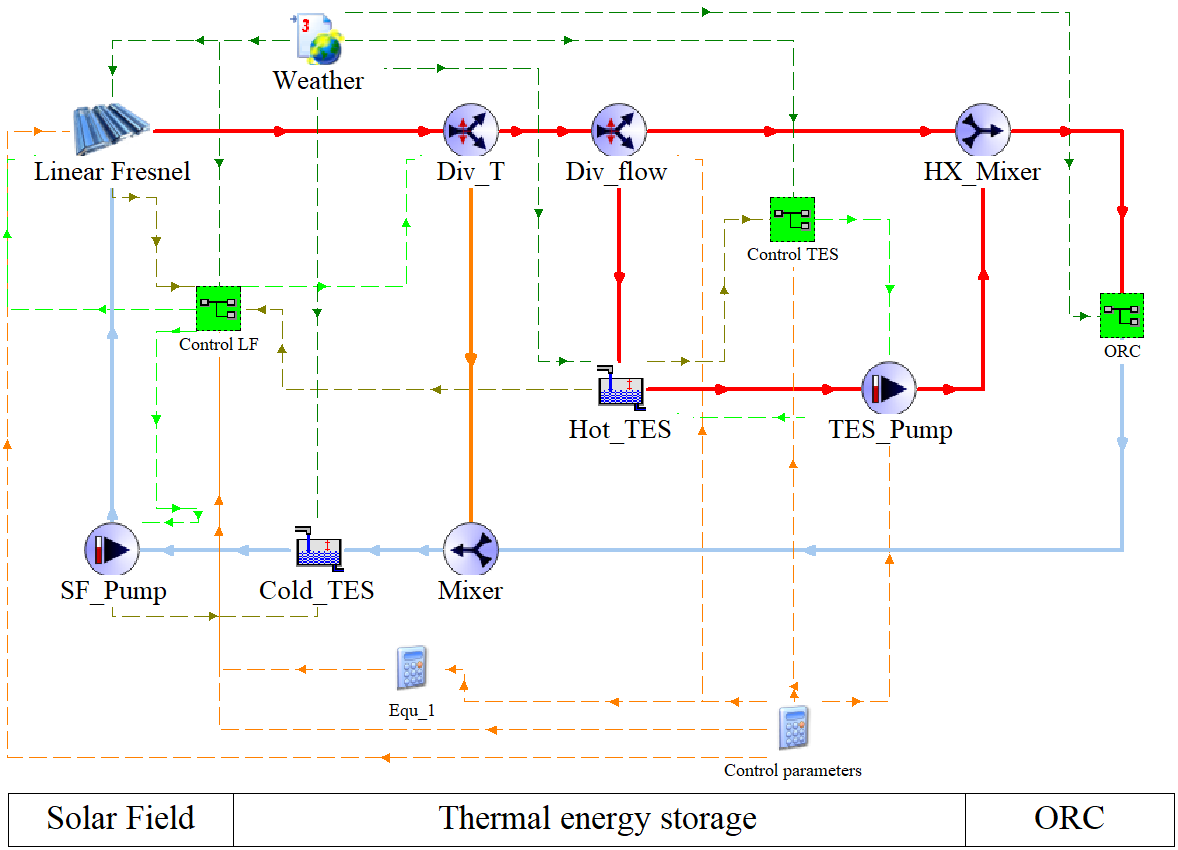

In addition to the implementation of more efficient and cleaner technologies/equipment, there is a clear need of improving the operation of the DHW and HVAC systems.

Many studies have demonstrated the viability of including Digital Twins in buildings. For example, IES indicates that, with the integration of a Digital Twin in the Riverside Museum of Glasgow, annual savings of £52.3k were achieved, with a Payback period below 6 months.

In order to achieve this savings, Digital Twins play a major role as they allow operate the system, for example, as a function of the weather forecast, historical data of demands, etc. in such a way nominal (more efficient) operation conditions are ensured in each scenario.

Furthermore, the use of this type of tools in the system design stage allow an optimized scaling of the components leading to cost reduction and to a more compact solution.

CIC energiGUNE’s capabilities towards Industry 4.0

In CIC energiGUNE in general and, the TES area in particular, we are experts in the development of this type of digital tools as key solutions to boost not only the Basque, but also the European industries, towards the fourth industrial revolution.

The know-how acquired by the researchers and engineers in different public funding projects (Hazitek, Plan Nacional, H2020, RFCS…), as well as in private contracts with industry in the last years, has allowed the creation of initiatives like Thermlab to offer this type of solutions to the industry.

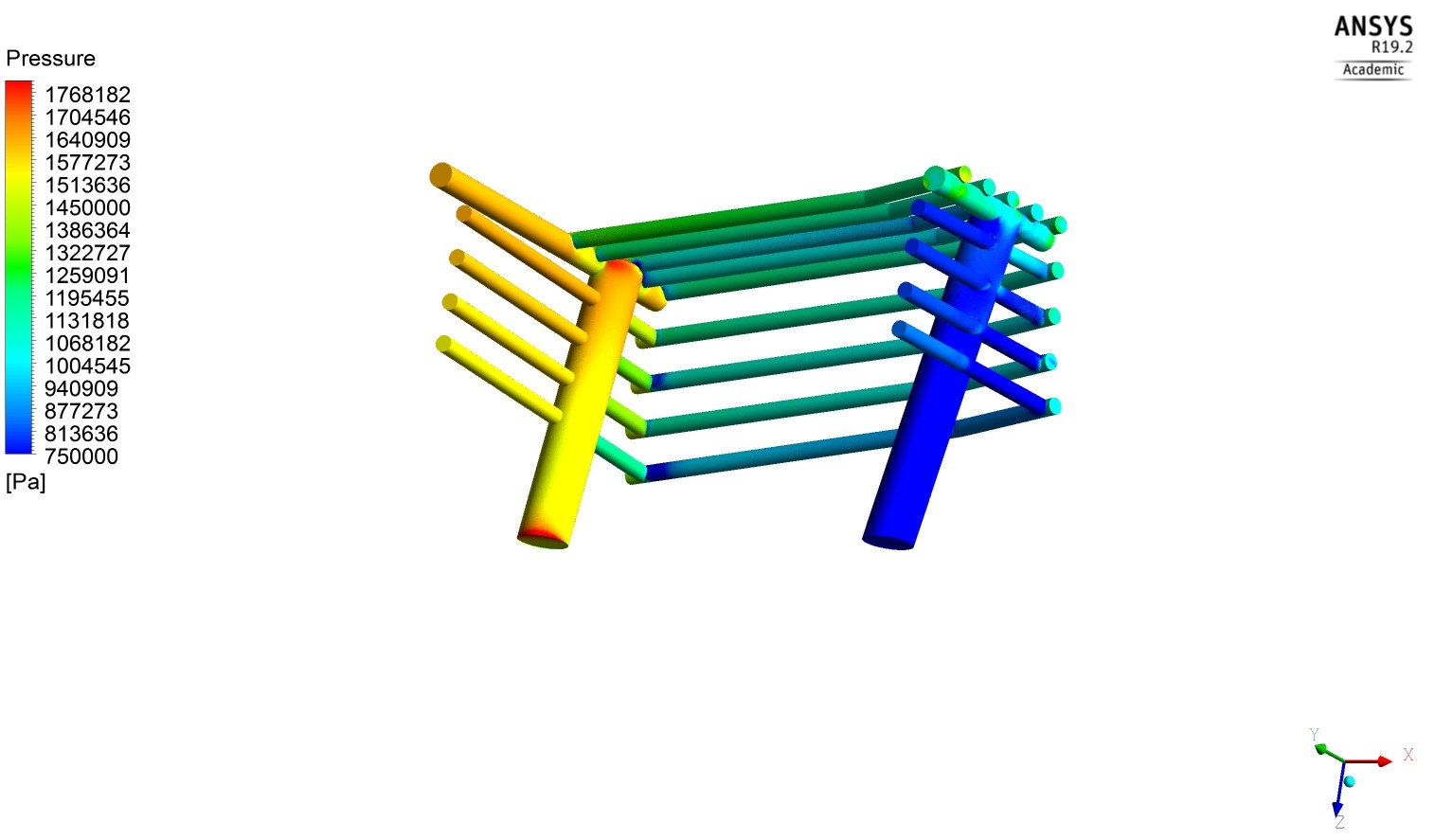

Currently, CIC energiGUNE counts with powerful modeling tools to accomplish this type of technological challenges such as ANSYS Fluent, ANSYS Icepak, TRNSYS or Matlab.