As the costs of lithium- batteries continue to fall and their performance improves, the electrified mobility era is now in full swing.

Lithium batteries are becoming increasingly common in our daily lives, powering everything from smartphones and laptops to electric vehicles and renewable energy systems.

However, this also means that in a few years, battery retirements will result in a dramatic increase in battery waste once they reach their end of life (EoL). Consequently, there is a growing need to find ways to recycle and recover valuable materials from them, while also minimizing environmental impact.

The economic and infrastructural challenges of spent battery processing discourage their proper recycling, and conventional recycling methods using pyrometallurgy and hydrometallurgy are energy-inefficient and generate secondary pollution, potentially undoing the environmental benefits of recycling.

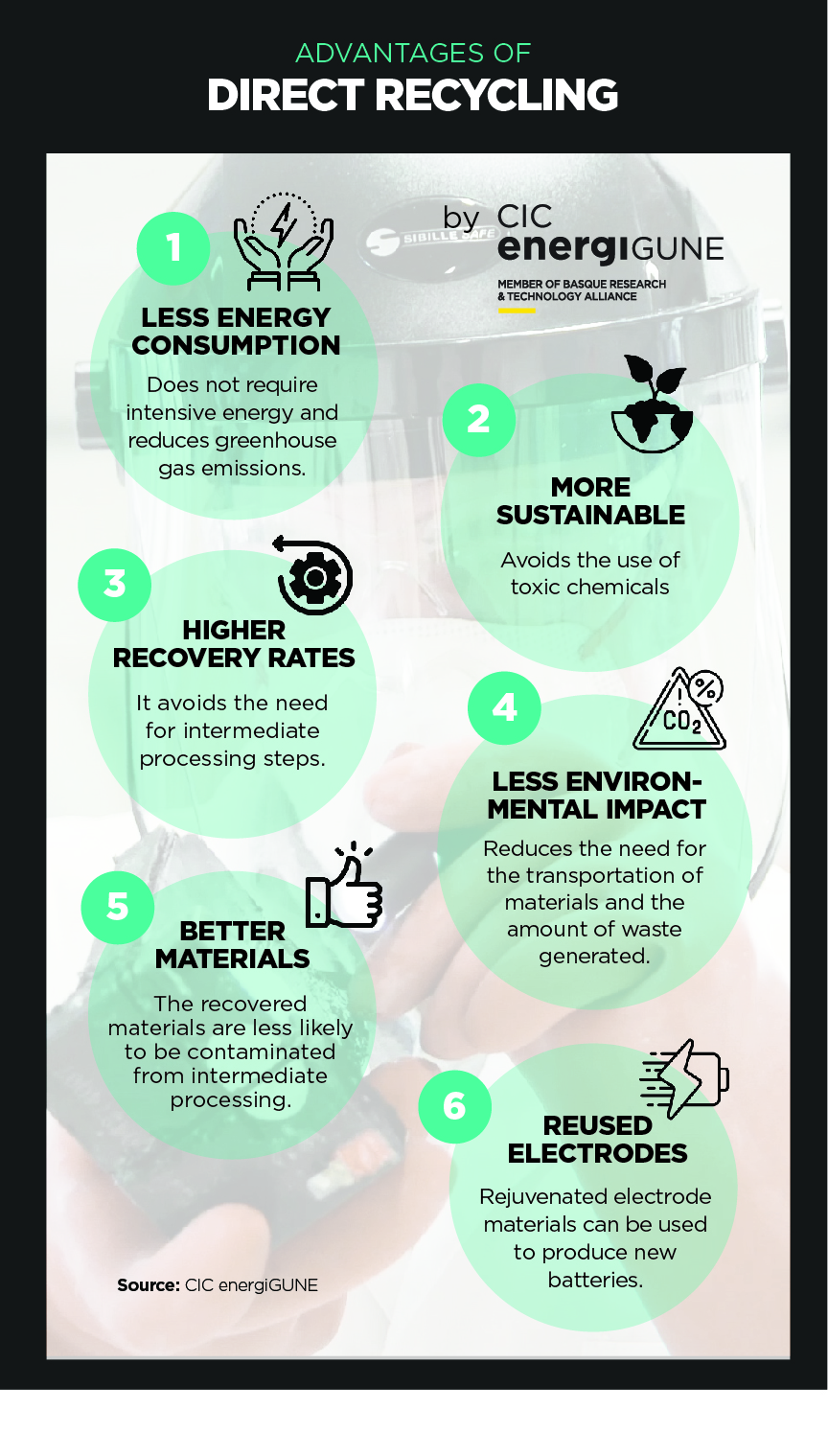

The advantages of direct recycling

Direct recycling, instead, aims to be a mild and green process that does not require intensive energy or chemicals, avoids the destruction of spent battery materials, and directly rejuvenates degraded electrode materials.

This new recycling process can output well-defined cathode materials with high value that can be directly used to fabricate new lithium batteries. Also, the regenerated active materials from direct recycling might be more valuable compared to elemental products from pyrometallurgical and hydrometallurgical recycling methods. In addition, it may also reduce energy consumption and greenhouse gas emissions while avoiding the use of toxic chemicals.

Some other advantages of direct recycling of lithium batteries can be summarized in the following points:

- Higher recovery rates: Direct recycling allows for the recovery of a larger proportion of valuable materials from the battery compared to other recycling methods. This is because direct recycling avoids the need for intermediate processing steps, which can result in the loss of valuable metals and chemicals.

- Lower energy consumption: Direct recycling also requires less energy than other recycling routes, which can help reduce greenhouse gas emissions and other environmental impacts associated with the recycling process.

- Reduced environmental impact: Direct recycling can help minimize the environmental impact of battery recycling by reducing the need for the transportation of materials between processing facilities and reducing the amount of waste generated during the recycling process.

- Better quality materials: Direct recycling can result in the production of higher quality materials, as the recovered materials are less likely to be contaminated by impurities from intermediate processing steps.