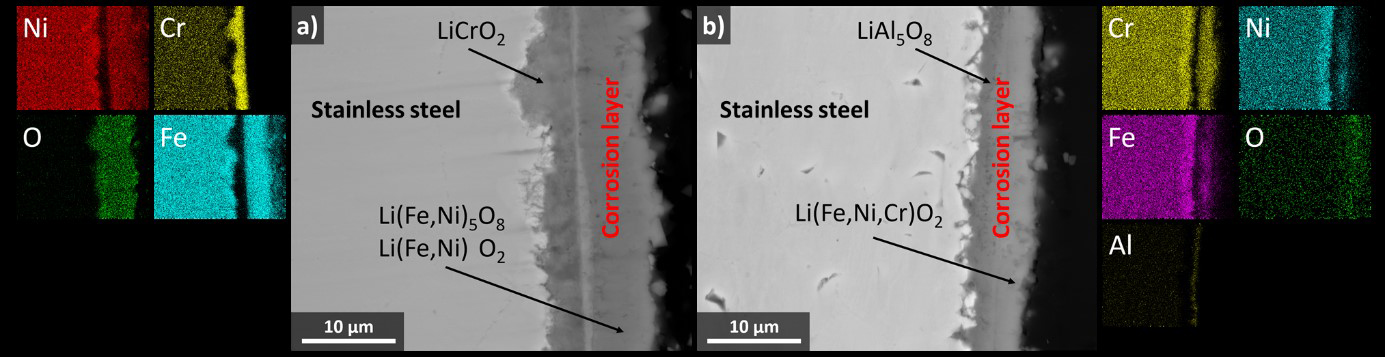

However, the compatibility of molten salts with construction materials at high temperatures is a significant challenge, which can put the feasibility of the whole technology in question.

This is particularly important for Thermal Energy Storage (TES) technologies, which implies thousands of tons of molten salt. Competitiveness and the final cost of large-scale TES solutions depend greatly on the use of low-cost construction materials, which is challenging due to corrosion. This is because molten salt is an electrolyte, which at high temperature poses high reactivity, particularly with metals, leading to sever oxidation.

The mentioned above challenges particularly manifested themselves within concentrated solar power (CSP) technology. CSP implies concentration of solar irradiation to generate heat, which later on can be transformed into electricity.

This renewable technology is particularly attractive when integrated with molten salt thermal energy storage unit. To reach high efficiency 3rd generation CSP is pushed to temperatures above 700ºC, which means use of molten chloride or molten carbonate salts for storing heat.

Nowadays, it became clear that successful implementation of this high-temperature CSP concept largely depends on resolving corrosion problems between molten salts and stainless steel at temperatures above 700⁰C, since the use of superalloys for TES storage tank increases the final price of the produced electricity beyond the market acceptable values.

At CIC energiGUNE we dive deep into the interfacial phenomena governing materials degradation to provide efficient practical solutions against molten salts corrosion for high-temperature thermal energy storage technologies.

To tackle this challenge, we rely on our state-of-the-art facilities and out-of-the-box approach, which resulted in several non-classical anti-corrosion methods.

Graphite: from problem to solution

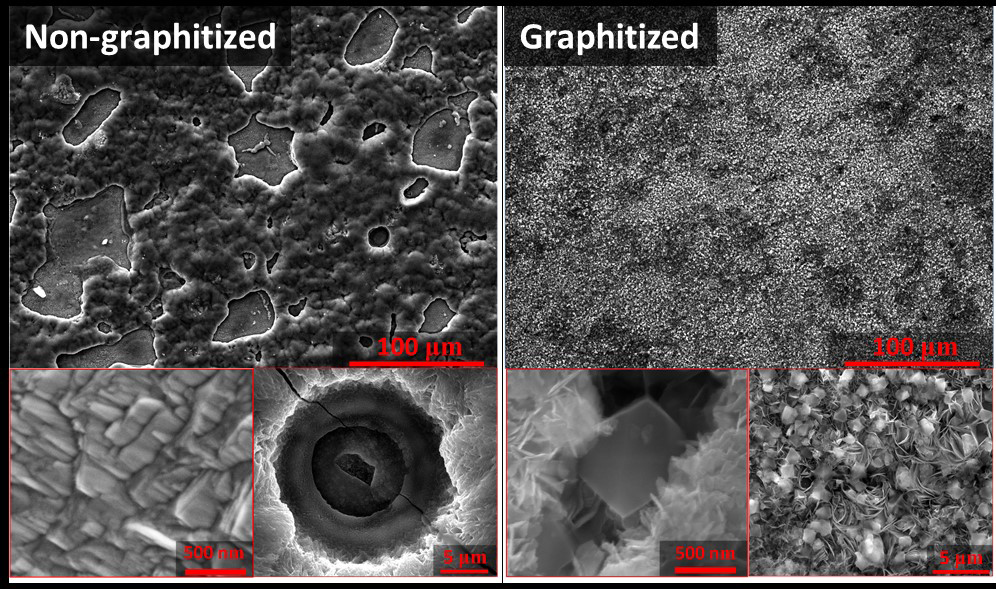

For example, by comprehensive analysis of the underlying chemical and physical phenomena, a Graphitization method to improve the compatibility of molten salts with a storage tank of concentrated solar power plants was developed.

It was not a trivial solution, as generally graphite is forbidden in the molten salt tank due to its decomposition at high temperature. However, the proposed method implies local decomposition of graphite at the “steel – molten salt” interface (the epicenter of the corrosion process) to form a protective layer and reach the passivation of the steel surface due to carbonates/carbides formation.

In this case, a very small amount of graphite is required to reach the protective effect, which does not affect the operational conditions of CSP plant and the properties of molten salts. Moreover, a highly undesirable localized corrosion was suppressed.