It is now a fact of life for everyone that the energy transition is a global priority whereby the transport, industry and buildings sectors will have to use more renewable energy. The International Renewable Energy Agency (IRENA) gives the keys to this transition in its annual report World Energy Outlook (WEO) 2018: the dominance of renewable energy and energy efficiency.

In this sense, the electricity sector is increasing its share of renewables to be the primary energy vector in this transition. Apart from the transport sector, which has been focused for some years on the vehicle fleet´s electrification, the industrial and residential sectors are key points to carry out this energy transition. The presence of renewables as a source of energy in both sectors is still below the necessary levels, so it is vital to promote their electrification. The direct use of renewable energies such as solar thermal and increased energy efficiency would be ideal for reaching where electrification cannot.

Whether for the electrification of these sectors, the direct use of solar thermal energy or the increase of energy efficiency, thermal storage appears as an essential pillar. Thermal storage makes it possible, among other things, to improve the flexibility of the electricity grid, overcome the intermittency of renewable energies, such as solar thermal, or take advantage of waste heat in industrial processes.

One of the biggest challenges to boost the market penetration of thermal storage lies in developing versatile systems, with a considerably higher thermal storage density than current ones, especially in applications where space is limited, and all this at a contained cost. For this purpose, thermal storage systems based on phase change materials (PCMs) are an interesting alternative.

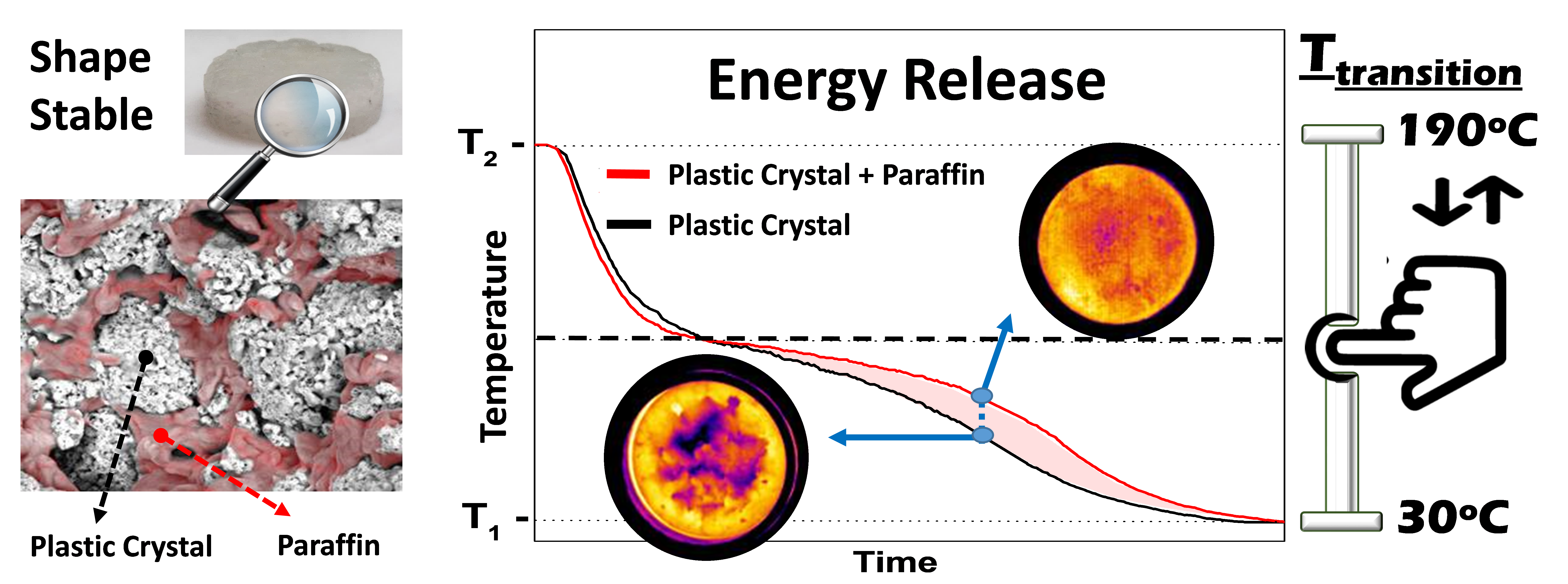

PCMs make it possible to store a large amount of thermal energy (in the form of latent heat) thanks to their phase changes (solid-liquid or solid-solid) while maintaining a constant temperature during the transition process. These systems offer a much higher storage density with a narrower temperature range between storage and heat release than those based on sensible heat, such as water tanks, prevalent in many of today´s building applications. Because of these properties, PCMs can be employed either as thermoregulating materials or as heat storage for narrow temperature ranges.

PCMs in buildings

Of the total energy consumption in Spain´s residential sector, 42% is for heating and 27% for air conditioning, while in the European Union these consumptions represent 64% and 15% respectively. Thus, the use of PCMs in this sector contributes significantly to the reduction of total energy consumption. Concerning their application in buildings, thermal storage systems based on PCMs can be classified as passive systems or active systems.

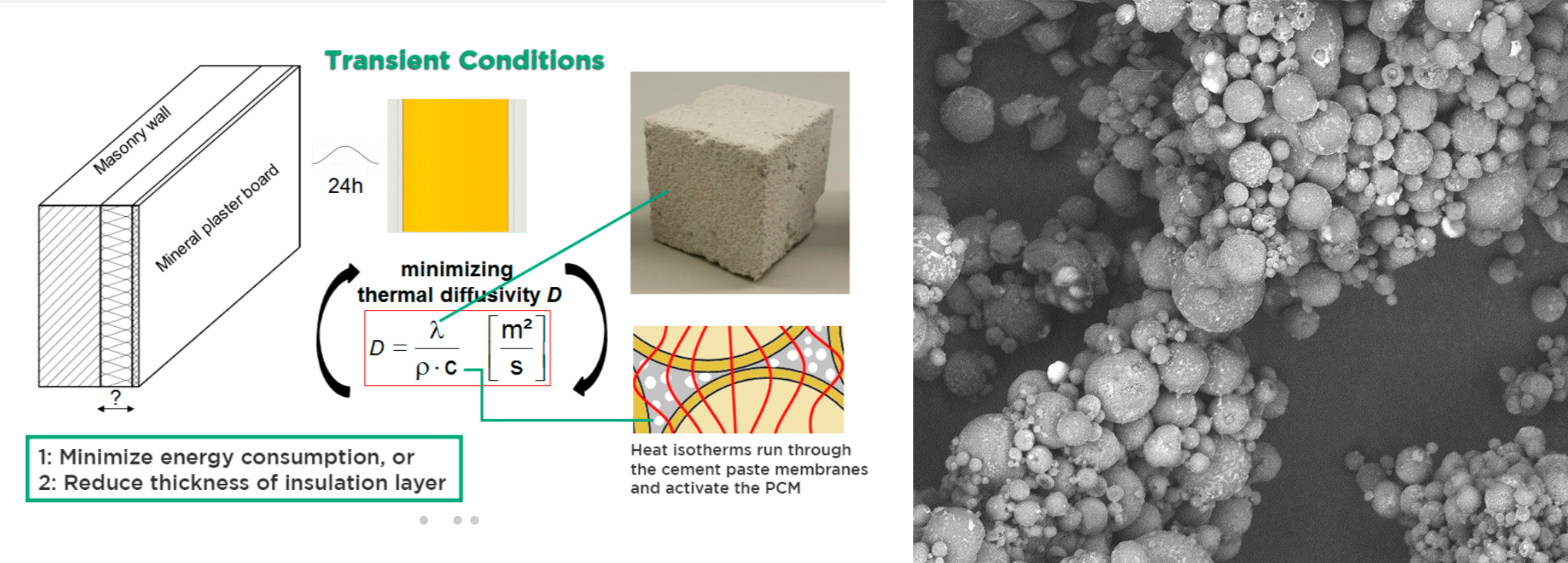

In passive systems, PCMs are usually integrated into the building elements themselves, such as gypsum panels, polyurethane foams, concrete or cement. These elements primarily have a thermoregulatory function, preventing rooms from overheating during the day in the warm months or reducing the need for heating at night in the winter. Passive systems can be combined with active ones to increase their effectiveness, thus favoring the complete charging and discharging of PCMs.

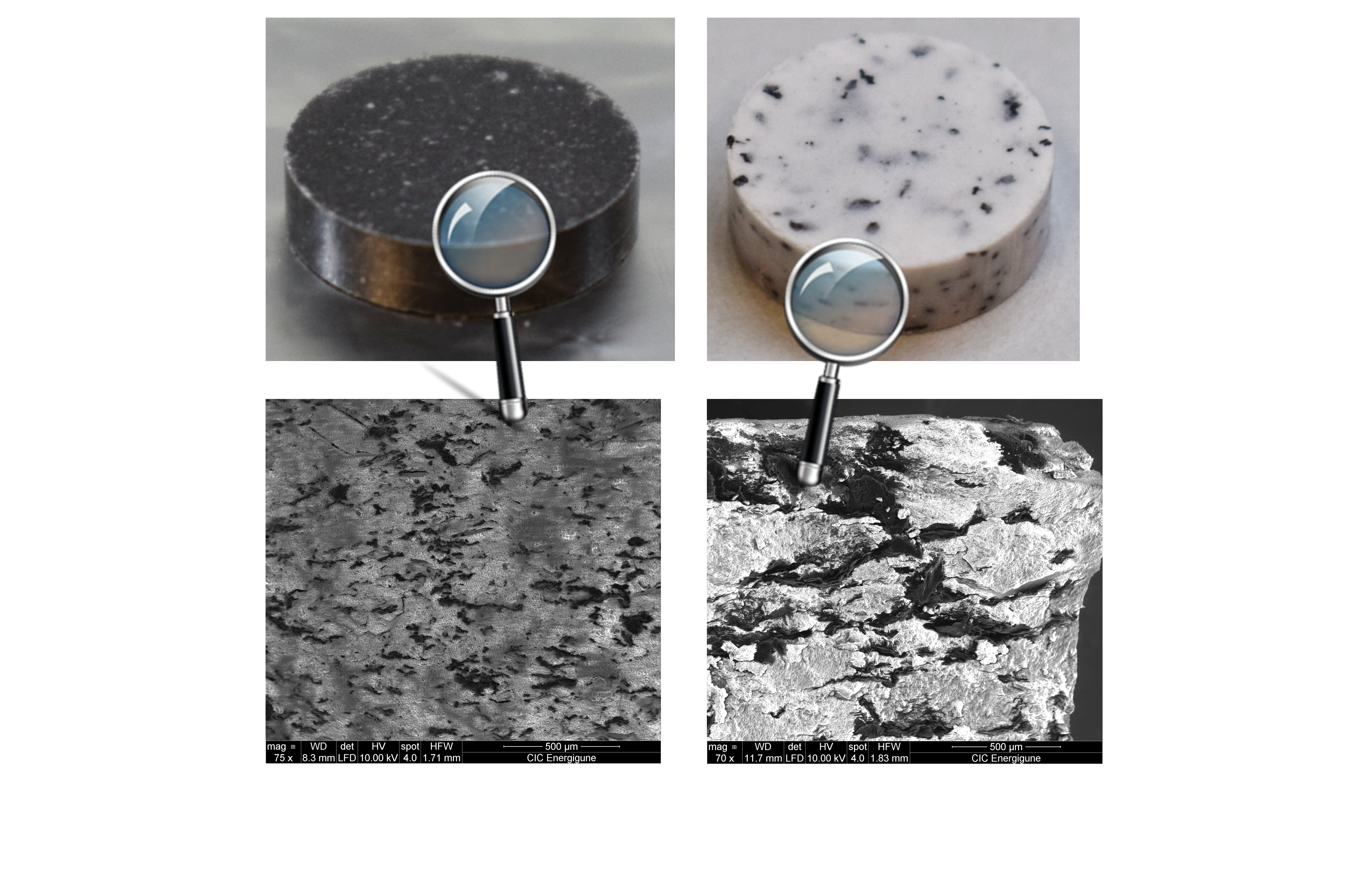

These types of solutions are present in CIC energiGUNE, as part of the NRG-Storage project, which aims to replace the current materials used in building envelopes with a novel, ultralight, non-flammable cementitious foam that allows active and passive energy storage. This is a highly innovative "green" option that combines the use of non-flammable and ultra-lightweight material with bio-based materials to create a multifunctional cementitious foam, called NRG foam.

CIC energiGUNE is mainly involved in the characterization of all the composite ingredients of this innovative material (cementitious paste doped with graphene nanoparticles and microencapsulated phase change material) to achieve the best fit between thermal insulation properties and heat storage capacity. The following image shows a conceptual scheme of the material developed in the framework of this project, as well as the microcapsules used in the doping of the foam.