Modern devices, from cell phones and computers to electric vehicles and servers, generate an enormous amount of heat. Without proper temperature control, the accumulated heat can compromise performance, reduce efficiency and shorten the lifespan of electronic components.

Thermal management, i.e., the ability to dissipate this heat effectively, has become a priority in the technology industry. Device designers are faced with the challenge of maintaining adequate temperatures in an ever-shrinking space, making the need to dissipate heat a key determinant of device efficiency and performance.

Current Solutions in Thermal Management

Today, the industry employs various solutions to control temperature in electronic devices, which fall into three main categories:

- Passive cooling systems: These systems do not require external power to operate. Heat sinks and thermal pastes are common examples. They work by channeling heat to larger surface areas or materials with high thermal conductivity, allowing it to dissipate into the air. However, passive solutions, while efficient in terms of energy consumption, have limitations in terms of the amount of heat they can dissipate and are often ineffective in situations of high component density or in environments with low airflow.

- Active cooling systems: These systems use fans, pumps or even advanced technologies such as liquid or compressor cooling. Although they are more effective in handling large amounts of heat, they have disadvantages such as additional power consumption, noise and larger size, making them difficult to integrate into compact and portable devices.

- Hybrid systems: Combine the advantages of active and passive systems. For example, a passive heatsink can be used in conjunction with a fan to improve heat transfer. While this can improve heat dissipation capacity, there remains the challenge of adapting to increasingly smaller devices, where limited space makes it difficult to include multiple cooling systems.

Despite these solutions, the reality is that many of them fail to fully adapt to the demands of modern devices. The reduction of space and the increase in power density generate the need to develop more efficient and versatile technologies that can manage large amounts of heat in diverse environments and in a customized way for each device.

CIC energiGUNE´s innovative approach: Advanced Materials for Thermal Management

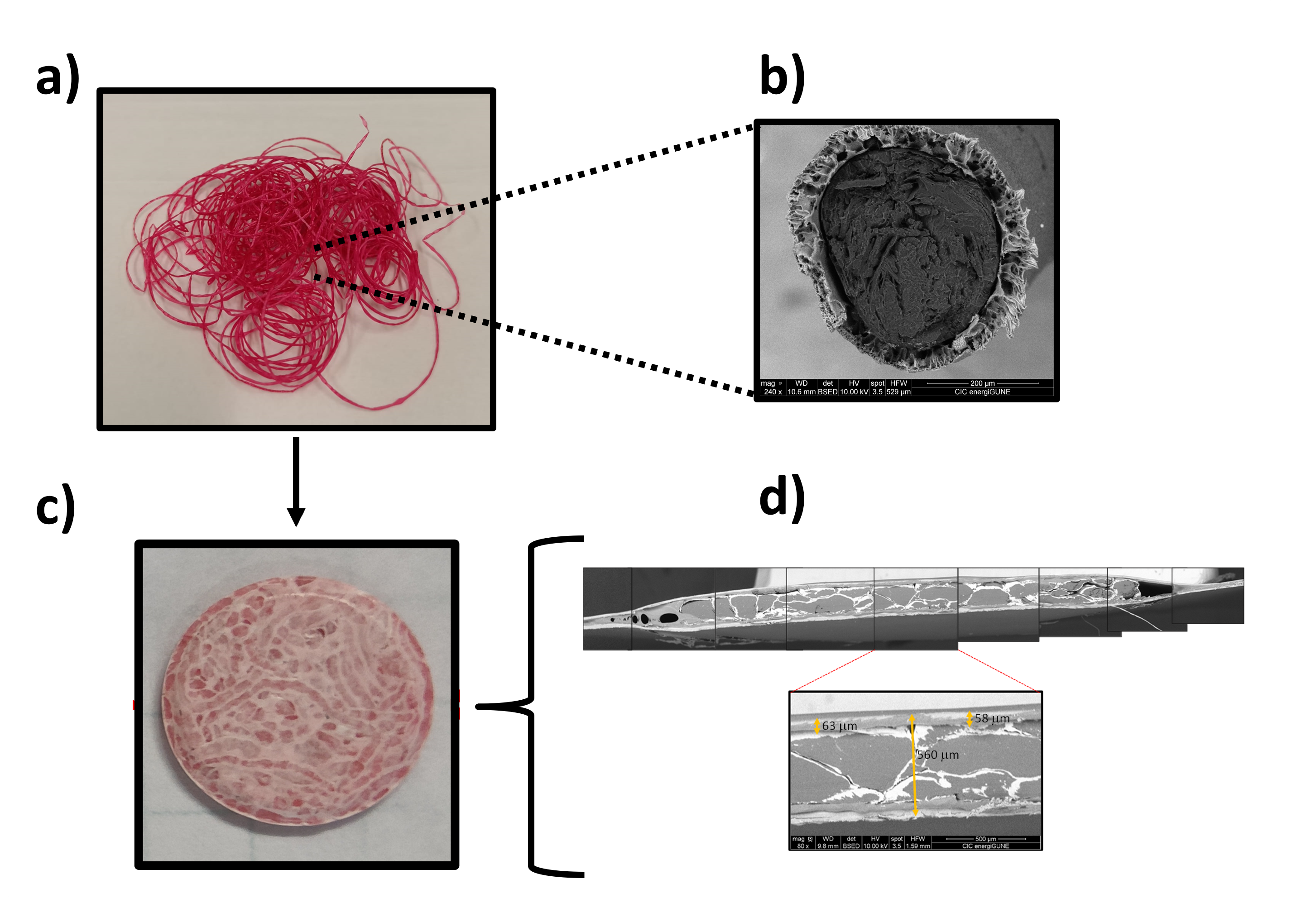

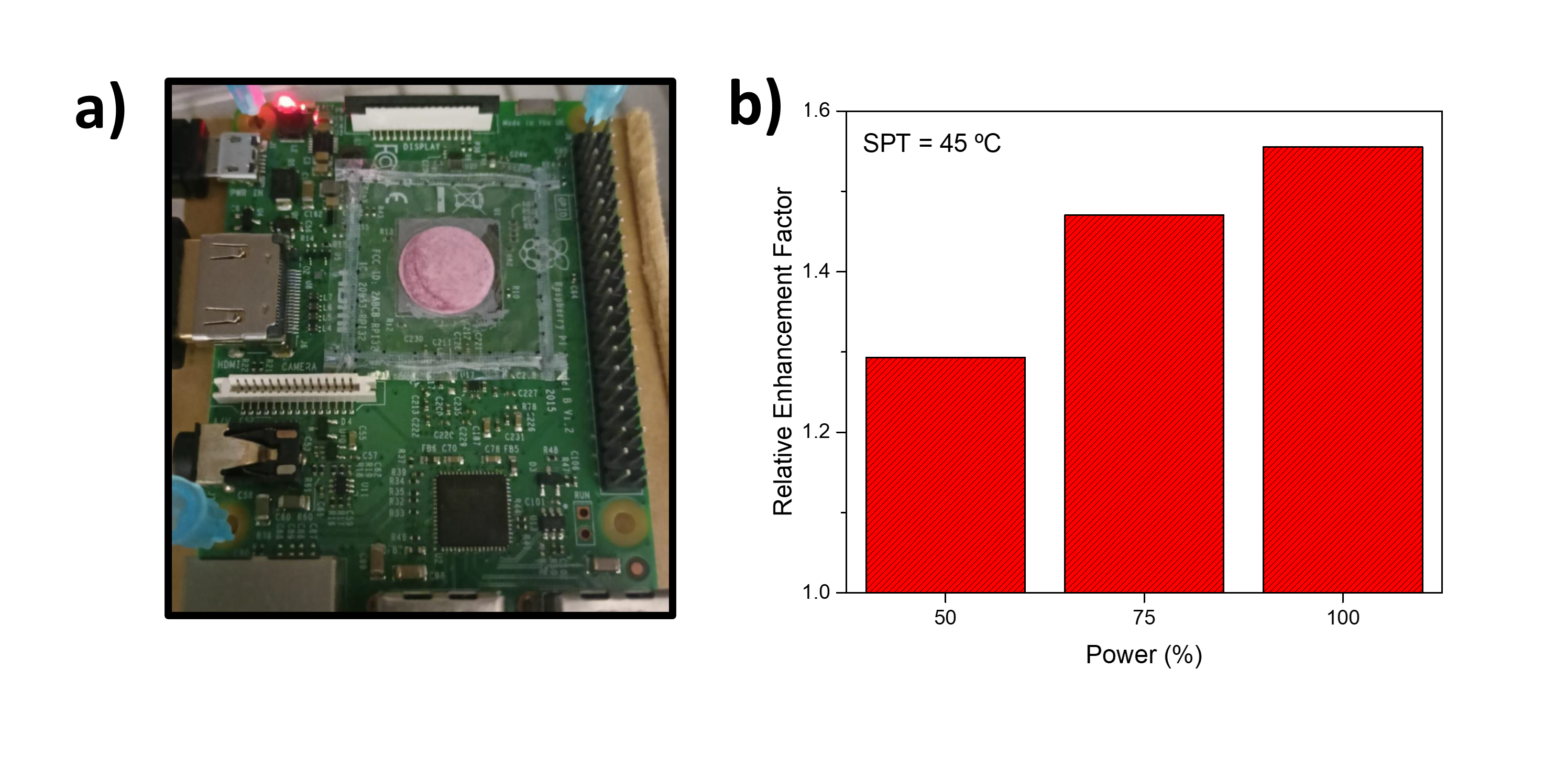

At CIC energiGUNE, we have developed advanced materials for thermal management, taking advantage of our deep know-how in the manufacture of fibers with thermal energy storage capacity. Thanks to this knowledge, we have been able to manufacture materials that not only dissipate heat efficiently, but also store it temporarily, delaying the heating of devices. This breakthrough has enabled us to develop flexible materials that can be molded in various geometries, adapting to the specific needs of different electronic devices and other industrial applications.