One of the most important challenges faced today is to respond to market requirements for energy storage systems. In this imminent energy transition context, users demand efficient, cheap and sustainable devices. CIC energiGUNE, as a research center in energy storage, works to meet all these requirements, and it does so from the most fundamental point of view: the improvement of the materials that compose these devices. That is why, betting on technologies that help us to understand the behavior of materials such as X-rays is vital to improve their properties in their subsequent application as energy storage systems.

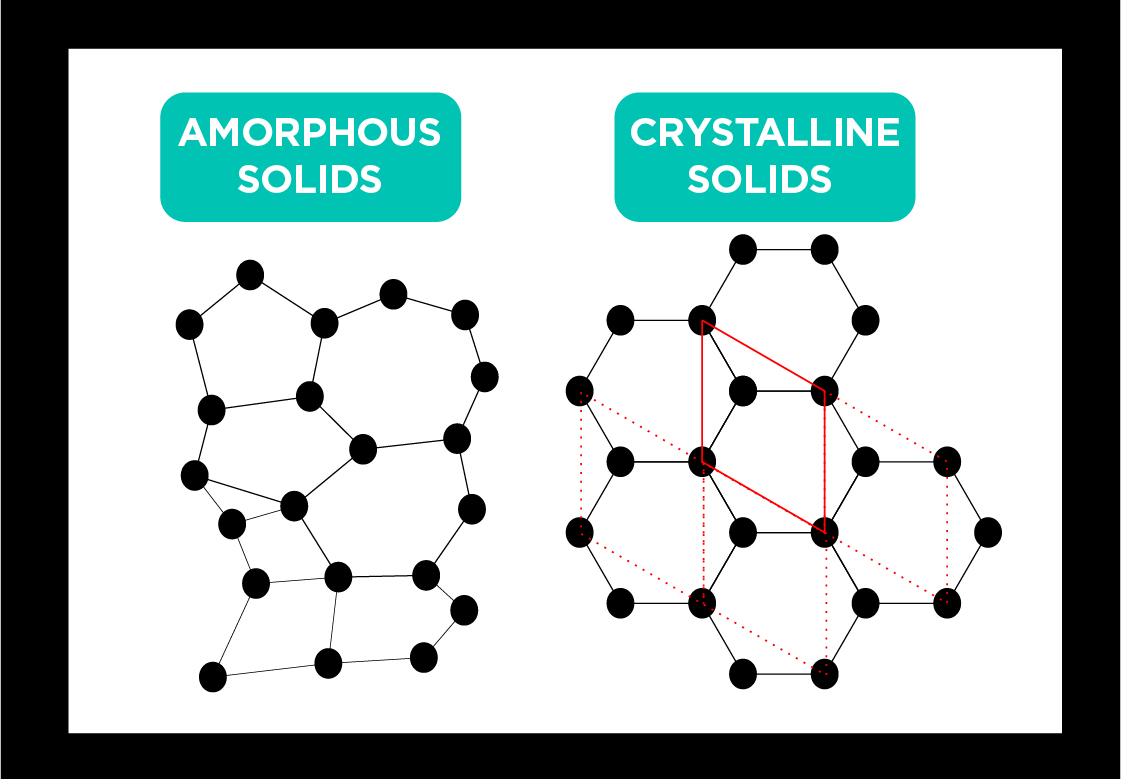

Amorphous and crystalline solid materials

Three are the most common material states with which everyone is familiar: solid, liquid and gas. While in liquid and gas the atoms (or molecules) have complete freedom of movement, in solids each atom has a specific position and its mobility is more limited. When these atoms are arranged in space in a disordered way (as we can see in the image below) they are called amorphous solids, while when they have a specific order and reproduce a pattern, they are called crystalline solids or crystals.

If you have ever looked at tiles while walking down the street, you will have seen how patterns are repeated and how, this effect is achieved by repeating a single tile infinitely. When we talk about a crystal structure, crystallographers use the unit cell to understand the structure of the material. And extrapolating again to the example, the tile would correspond to that unit cell. In other words, the unit cell is the smallest unit that, if repeated in all directions, generates the structure of the material. In the image the unit cell of the crystal structure is shown as a red rhombus and it reproduces itself in all directions (adjacent rhombuses with intermittent lines).

X-rays can give us some relevant information about amorphous solids. In fact, CIC energiGUNE has among its equipment a SAXS (small angle X-ray scattering) diffractometer which is used, among other functions, to know the short-range ordering or the porosity of amorphous or poorly crystalline compounds. In any case, X-rays are really relevant is in the characterization of ordered materials. Moreover, X-ray diffraction is a routinary technique for characterizing materials all over the world as they are used to determine the crystalline structure of solids by extracting information about how the atoms in the solids are arranged with high accuracy.

But, how are X-rays able to give us such information?

Max Von Laue predicted that, if atoms are regularly arranged in a crystal, when a sample is irradiated with an X-ray beam, some of the rays would diffract. And he was not mistaken because this theory was demonstrated in 1912 by Paul Knipping, Walter Friedrich and Max Von Laue himself. William Henry Bragg and his son William Lawrence Bragg studied this diffraction and developed Bragg´s law, which describes a series of conditions under which diffraction occurs and which allows us to correlate the angle of diffraction of X-rays with the positions of the atoms within the structure.

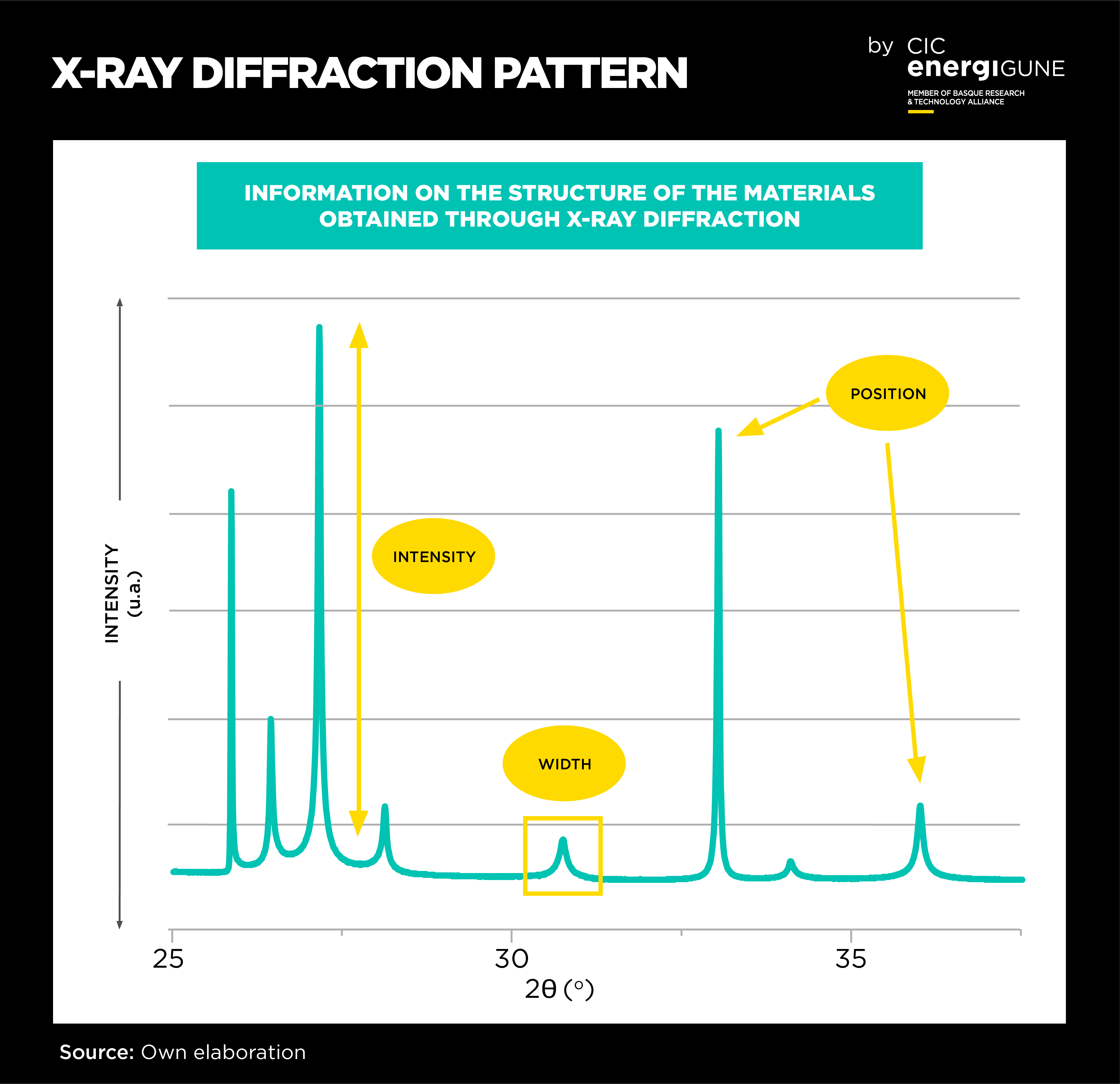

Generally, when a material is exposed to an X-ray beam the diffracted rays generate a diffraction pattern consisting of a series of peaks with different intensities and shapes, as shown in the following image. Using complex mathematical operations carried out with specific software such as FullProf, it is possible to obtain very relevant information about the structure of the material. Roughly speaking, the position of the peaks is determined by the size of the unit cell; the intensity of the peaks by the nature of the atoms and their position within this cell; while the peak profile (i.e., the width and the shape) gives information about the size of the crystallites and other considerations such as defects. The importance of defects in crystalline materials and how the FAULTS software helps us to describe them has already been covered in a previous article written by Dr. Marine Reynaud.

Operando X-ray diffraction

A characterization technique that is very much in vogue due to its great usefulness is operando X-ray diffraction . This technique consists of acquiring X-ray patterns at the same time as the material is exposed to a particular use. In the case of battery materials, these measurements are taken while charging and discharging them. In this way, we can observe what is happening to the material at the different states of charge and this helps us to know how the battery behaves during their use, something essential to be able to improve them.

In addition, since the speed of data acquisition is of vital importance, high intensity X-rays are very convenient (the higher the intensity, the less time is needed to obtain quality data), so it is very common to perform these measurements in synchrotrons such as ALBA in Barcelona or ESRF in Grenoble, which are scientific facilities where X-rays are generated at substantially higher intensities than in conventional laboratories.

At CIC energiGUNE, the X-ray diffraction platform is composed of three state-of-the-art equipments that allow us to cover the analysis of a very wide range of lengths, from the atomic crystal lattice to morphological information at the nanometer scale. In addition, we collaborate assiduously with scientists from ALBA and other synchrotrons and we have developed a special cell to make operando measurements both in synchrotrons and conventional X-ray equipments.

As it has been shown, X-ray diffraction is an ideal characterization technique to obtain a large amount of structural information that is absolutely necessary for the development of advanced materials. This is why CIC energiGUNE has a team of experts in diffraction that can help to improve the materials to be at the forefront of research. In addition CIC energiGUNE provides service and support to those centers, both academic and industrial, that need it.