DANIEL BIELSA LINAZA

TECHNOLOGY COORDINATOR

TECHNOLOGY COORDINATOR

Thermal analysis platform is aimed to the thermo-physical characterization of a wide spectrum of samples (solid (bulk, powder), liquid). The platform includes high tech instrumentation such us Simultaneous Thermal Analysis (STA) coupled with a Mass Spectrometer and Differential Scanning Calorimetry (DSC) for thermodynamic characterization, Laser Flash Apparatus (LFA) and a Dilatometer for physical measurements. The services are provided for research groups within the center as well as to the external users like other research centers or other public organization, but also to commercial companies and private people.

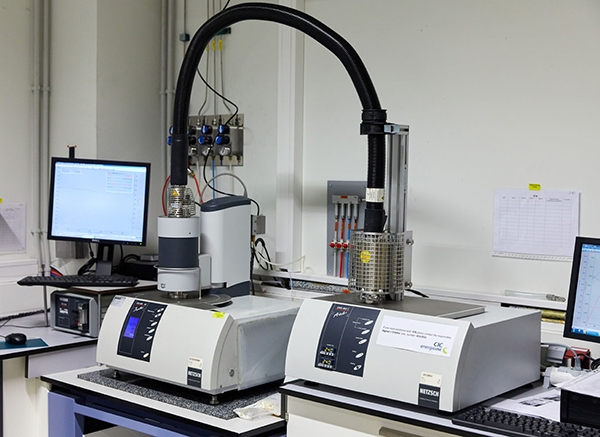

Simultaneous Thermal Analysis (STA) refers to the simultaneous application of Thermogravimetry (TG) and Differential Scanning Calorimetry (DSC) to one and the same sample in one instrument. Additionally, the system is connected to a Quadrupole Mass Spectrometer (QMS) in order to analyze gases, and in particular, volatile decomposition products of thermal analysis.

Features:

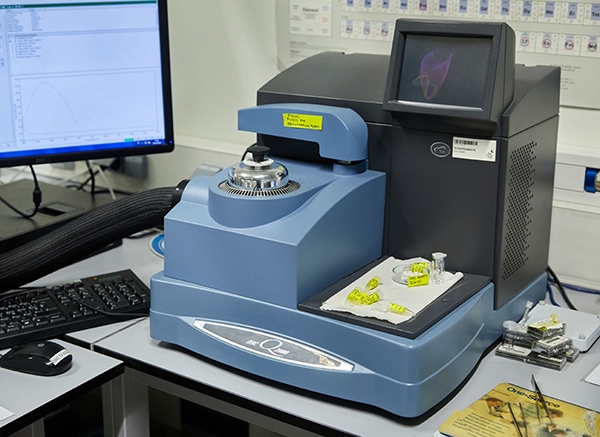

The Q2000 is a research-grade DSC with superior performance in baseline flatness, precision, sensitivity, and resolution. Advanced Tzero® technology and multiple exclusive hardware and software features make the Q2000 powerful and flexible.

Applications:

Features:

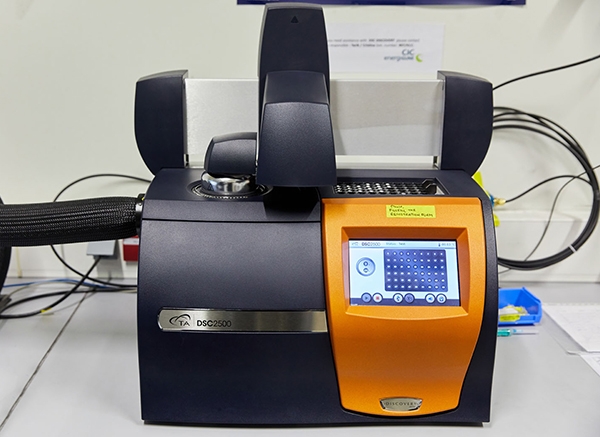

The Q2500 is the best on the market research-grade DSC with superior performance in baseline flatness, precision, sensitivity, and resolution. Advanced T4P Tzero® technology and multiple exclusive hardware and software features make the Q2500 exceptional option for high precious measurements of heat capacity and characteristics of phase transitions.

Features and Benefits:

The LFA 457 MicroFlash® is the most up-to-date and versatile Laser Flash Apparatus (LFA) system for research search and development of applications involving characterization of standard and high performance materials in automobile manufacturing, aeronautics, astronautics and energy technology.

Features:

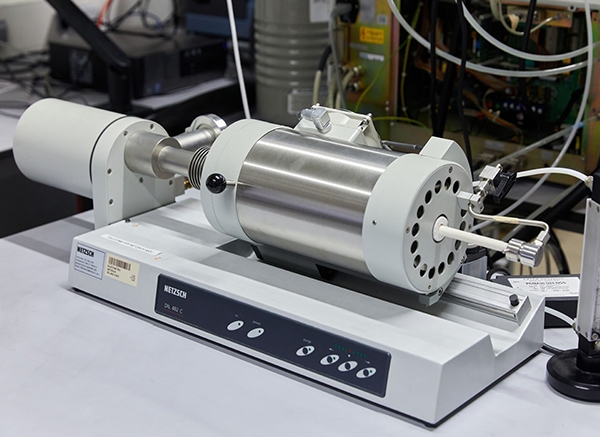

Pushrod dilatometry is a method for determination of dimensional changes versus temperature and time when the sample undergoes a controlled temperature program. The specific materials properties gathered from this are: thermal expansion, coefficient of thermal expansion, volumetric expansion, density change, sintering temperatures and shrinkage steps, glass transition temperatures, softening points, phase transitions and influence of additives.

Features:

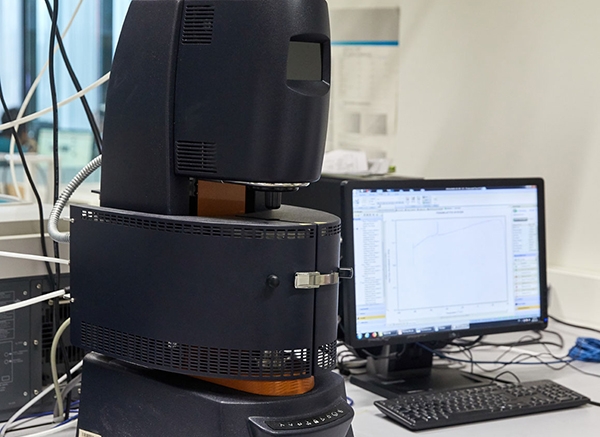

This rheometer uses FRT technology, provides the most accurate normal force measurement because the linear motor is driven to maintain zero deflection. The FRT and the patented magnetic bearing technologies enable axial Dynamic Mechanical Analysis (DMA) capabilities on every DHR, permitting amplitude-controlled oscillatory deformation in the axial direction. Now in addition to the most sensitive and accurate rotational shear measurements, the DHR can deliver accurate linear DMA data as well without the installation of external components

Currently we have two different heating systems:

If you want to know the latest trends in energy storage and new developments in research, subscribe.

If you want to join a top-level team, collaborate with specialists in multiple disciplines or tell us about your concerns, don't think twice...