Global demand for sustainable rechargeable batteries is expected to increase dramatically over the next decade as applications continue taking off. Lithium-ion batteries (LIBs) are the most powerful high-capacity rechargeable batteries on the market today, but they have almost reached their theoretical energy density limit and therefore exploration of new systems and chemistries is mandatory.

Taking on this challenge requires new disruptive approaches and better tools to accelerate the discovery and understanding of new electroactive materials. To this end, several research groups have proposed strategies to identify, theoretically, new potential candidates more efficiently through the use of computational chemistry.

Within the framework of the ION-STORE project, CIC energiGUNE has developed a computational tool based on Bond Valance Theory (BVT). This tool allows accessing crystallographic databases and identifying structures that have been previously used in other fields and that could be potential candidates to be used in the battery field. In this way, numerous families of compounds have been identified but, although they help to advance in the discovery of new materials, they cause a bottleneck during the experimental validation stage. Hence, having identified this limiting stage, the development of the ION-SELF project was proposed, which focuses on accelerating the ratio of synthesized samples.

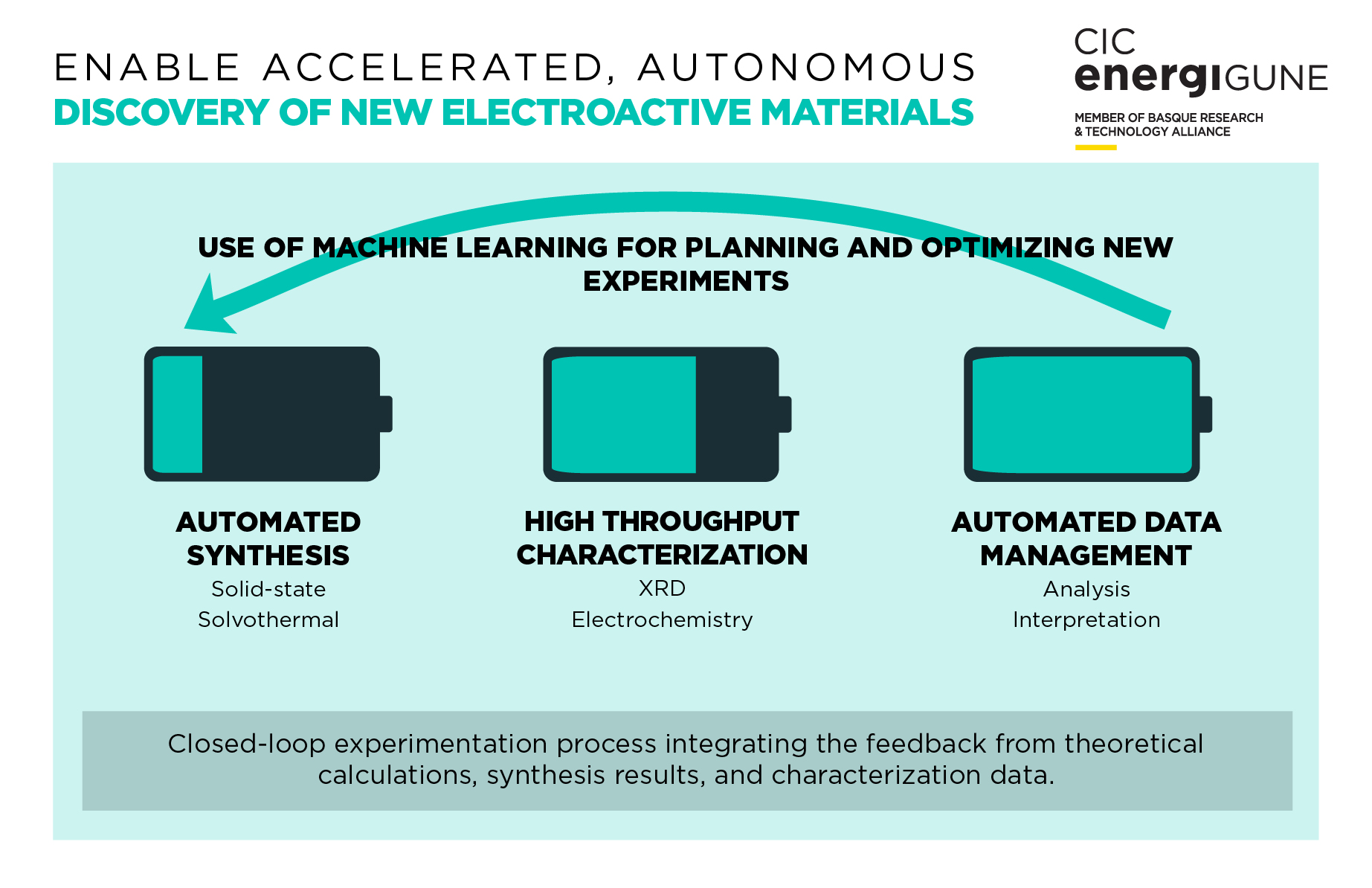

Within the ION-SELF project, we are working to enable the accelerated and autonomous discovery of new electroactive materials. To this end, we are focusing on the automation of the synthesis and characterization processes, of the data treatment itself and even of the planning of new experiments by using automatic modules and artificial intelligence. In this way, at the end of the process we will have a closed experimental loop integrating feedback from theoretical calculations, synthesis results and characterization data.

A novel, validated and reproducible sample preparation module

More specifically, at CIC energiGUNE, we have developed a novel, validated and reproducible high-throughput automatic module for laboratory-scale sample preparation of electrode materials. This module is intended to handle and mix precursor solutions at suitable stoichiometries to be evaporated prior to solid-state annealing treatment. This approach allows building a configuration compatible with a wide range of synthesis routes such as sol-gel, Pechini, co-precipitation based synthesis, etc., which itself allows morphological and size control and/or in situ carbon coating of the particles to improve ionic conductivity.

After establishing the design of experiments, we link this information with the module code that is written in Arduino -the open source electronics creation platform based on free hardware and software-. We upload this information to the Arduino Mega board installed in the automatic module and the reagents start mixing for each of the crucibles that we place under that module, with a wash of the system with distilled water occurring between each mixing phase. In addition, it should be noted that, after uploading the program to the system, the presence of the researcher is not required, who can dedicate himself to data processing without the need to be in the laboratory.

Depending on the complexity of the synthetic route, a researcher usually prepares between 1 and 20 samples in a week. However, with this automatic module we are now able to synthesize 60 samples in the same period of time. In addition to achieving a 10-20 fold increase in the ratio of samples synthesized, we have also achieved a more reproducible method by eliminating human error.

The use of this technology allows us to make a quick and efficient scan of the families of materials identified theoretically, which translates into an acceleration of the process of discovering new materials.

In addition, as we mentioned at the beginning, the next phase of the ION-SELF project is the automatic characterization of all the samples produced. For this purpose, we are working on two other modules that allow us to prepare in an automated way, both the samples to be measured by X-rays and the test cells that allow us to check the electrochemistry of the materials.

Thanks to the use of these modules, we are able to substantially reduce not only the time needed for experimentation but also the costs involved, which brings us closer to the discovery of alternative batteries that offer more capacity, safety and a longer useful life; an essential goal in order to achieve the total decarbonization of the economy and a more sustainable future.

Note/acknowledgements: Related research works developed at CIC energiGUNE have received funding from the Spanish Ministerio de Ciencia e Innovación and Agencia Estatal de Investigación (MCIN/ AEI /10.13039/501100011033) through the project ION-SELF (ref. PID2019-106519RB-I00).