Lacking better strategies, the search for new materials has traditionally consisted of relying on chemical intuition to first select the systems with the best properties, then synthesize them in the laboratory and finally measure their viability in a process of trial and error that was not very efficient, essentially based on a serendipity that was not always there.

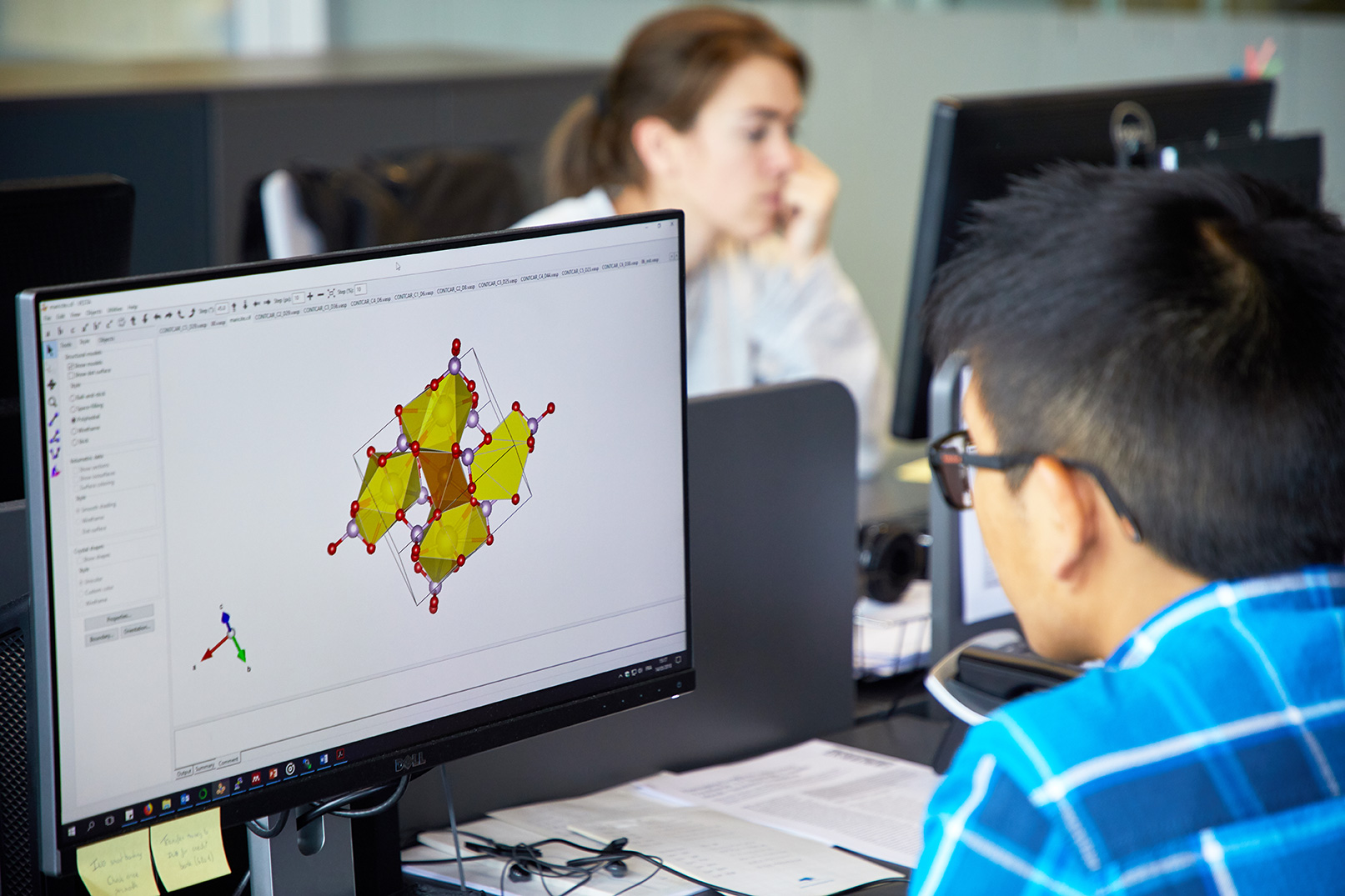

Today´s theoretical chemistry makes it possible to turn this process based on intuition and serendipity into a rational search, based on real calculations and without discarding potentially valid structures a priori.

This is possible thanks to the physical basis of current quantum-chemical theories, which allow us to describe, theoretically, the behavior of materials and their properties. In other words, it is possible to predict how a given material may respond without the need to physically dispose of it.

This optimized prospecting of new materials for energy storage represents a cost advantage, and is, at the same time, the cornerstone to improve competitiveness in a key sector for society and crucial to achieve the objectives of the energy transition.

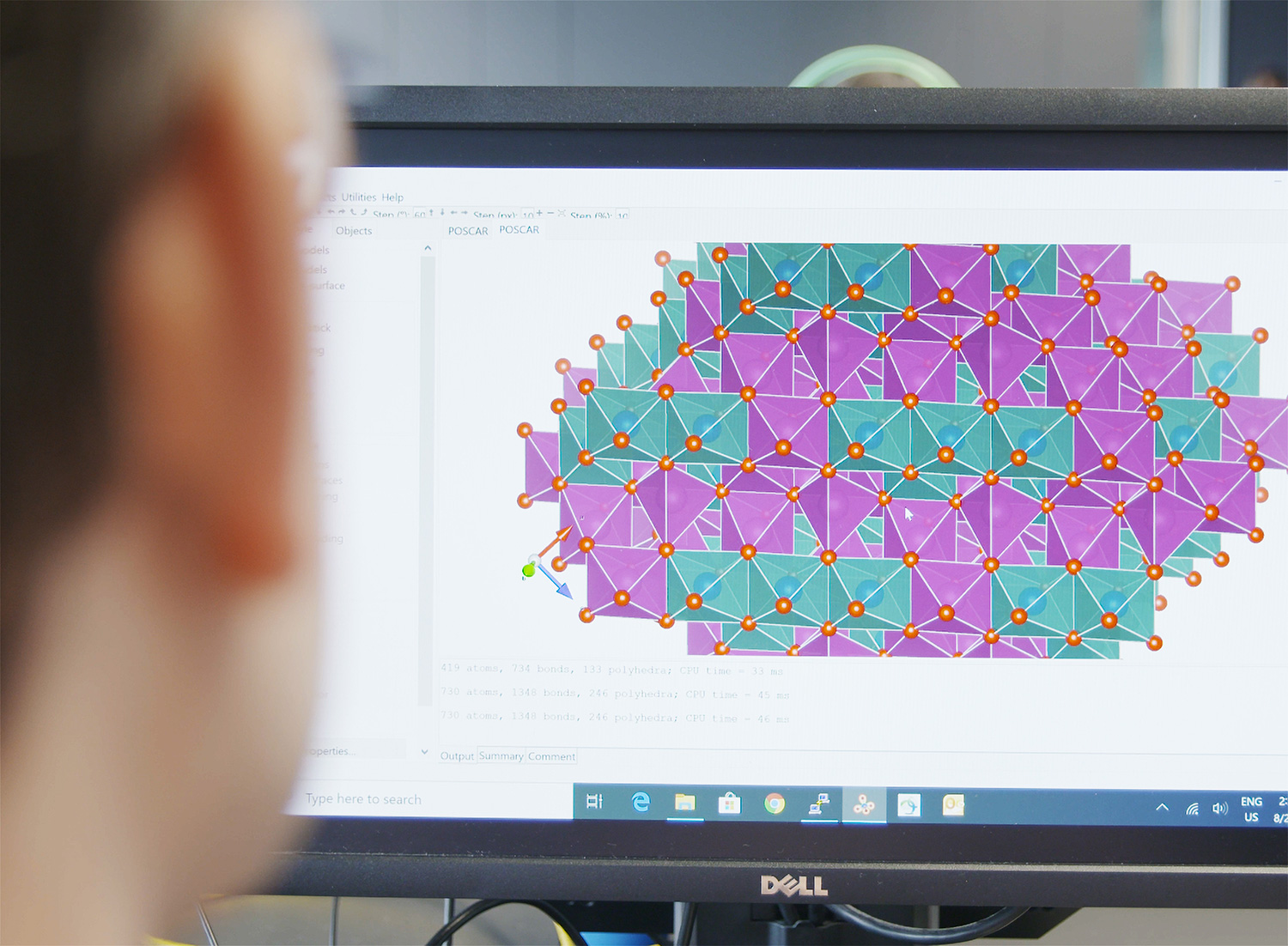

In order to better explain what these techniques consist of, we can use as an example the argyrodite, a mineral that CIC energiGUNE works with and on which there are numerous theoretical works. It is a crystalline solid with interesting properties to be used as electrolyte in solid-state batteries. This is because it contains channels in its structure through which the migration of ions such as Li+, in the case of lithium batteries, is possible.

Argyrodites, as found in nature, are canonically made up of one or two metals, typically silver (Ag) and germanium (Ge), and a chalcogen which is usually sulfur (S). However, would combinations between other metals also be stable? And with other chalcogens, such as oxygen (O) or selenium (Se)? Could the latter be replaced by halogens (F, Cl, Br or I)?

If we do not exclude in advance any metal, halogen or chalcogen, there are millions of possible combinations, which makes it impossible to comprehensively synthesize all these structures in the laboratory and measure their properties.

This is where the potential of computational simulation studies comes in, allowing the efficient identification of new combinations with new properties to open up a range of possibilities for the industry.