Requirements from mobility and stationary markets

One of the key components in an electric vehicle is the battery. To be competitive with internal combustion engines, the battery must be safe, ensure a competitive driving range and be at a low cost. The automotive industry requires batteries with high energy density -so one can drive from Vitoria-Gasteiz to Barcelona on a single charge (600 km)-, and high-power density for safe accelerations. This, in figures, represents a cell of 450 Wh/kg and 900 Wh/L as well as more than 5000 W/kg as short current peaks.

At the moment, most lithium-ion batteries contain a liquid electrolyte which, although it is very efficient in transporting ions between the cathode and anode, has the disadvantage that it can react and become flammable in the event of physical damage or misuse. Solid-state battery technology is an advance over these disadvantages, as its safe, non-toxic electrolyte is capable of replacing its liquid counterpart.

Solid-state technology will not only benefit the mobility market but will also be integrated into stationary applications. The market predictions foresee an exponential increase of stationary energy storage for home utilization and larger industrial sites such as wind farms.

Solid-state batteries: what are they?

Thanks to the combination of metallic lithium anode with high voltage cathode active material, the solid-state technology is currently the only technology to reach the automotive requirements, the most challenging and demanding in terms of performance.

Li metal presents a capacity to accommodate lithium ions ten times higher than graphite -the anode material currently used in the Li-ion technology-. With a limited amount of cobalt, high voltage cathodes can reach high capacities but cannot be used safely in the current technology. The successful integration of this unique combination of materials will be a game-changer. Solid-electrolytes is, then, becoming the holy-grail.

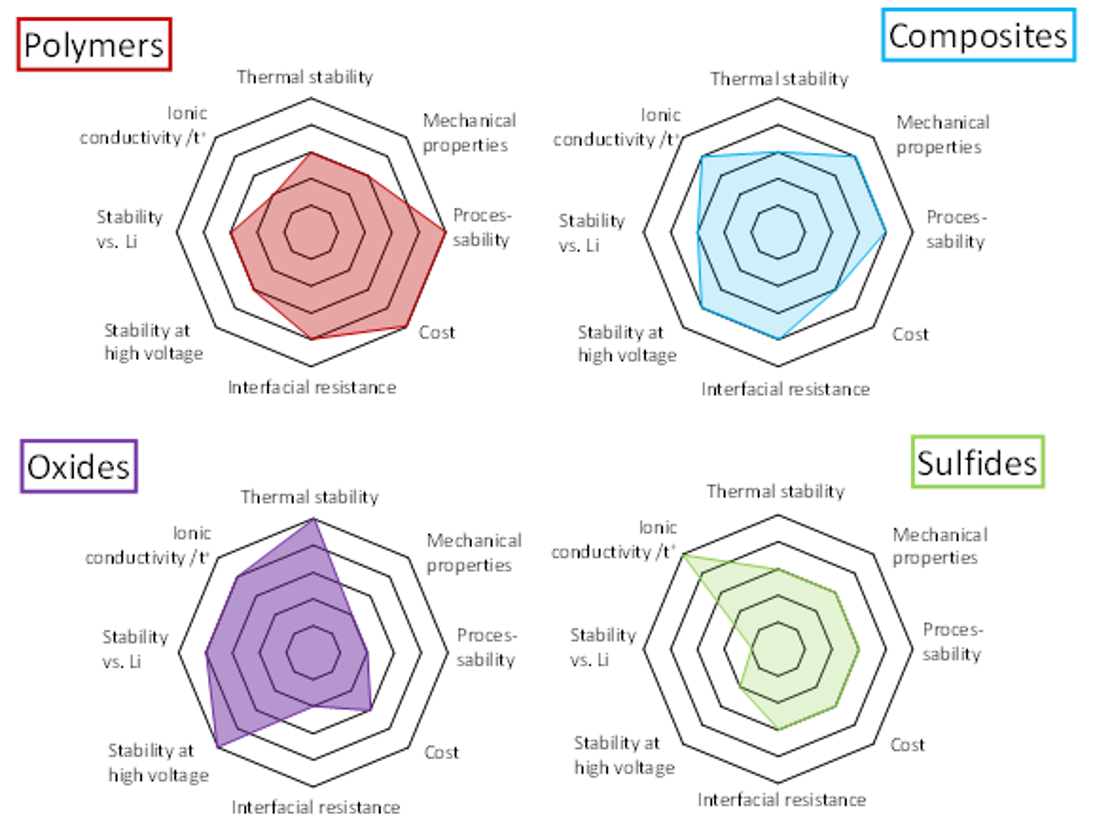

Different families of solid-state electrolytes have emerged and are competing to enter the market:

- Polymer electrolytes: are easily processable, present a low cost and are made of abundant resources. These materials are lacking on performance at low temperatures and for power applications.

- Inorganic electrolytes: these materials, composed of oxides or sulfides as the most representative, are undoubtedly serious contenders. Their competitive performances are very attractive, but major challenges remain for processing and decreasing these materials´ hazard level.

- Composite electrolytes: a combination of polymer and inorganic electrolyte that take profit of the advantages of each other’s. The correct combination may most probably be the winning electrolyte technology.

Researchers at CIC energiGUNE have more than 10-year experience developing solid-state batteries and are closing the gap between research and development and cell production. The father of solid-state battery technology, Professor Michel Armand, is part of our research team, a mentor and an example that our young research team is imitating.

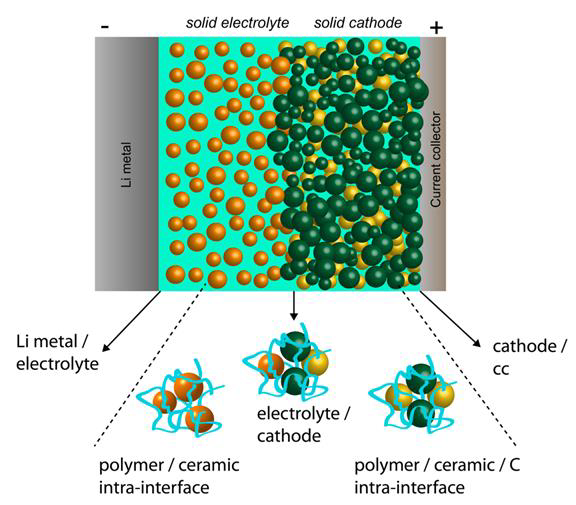

The integration of solid-electrolytes in a multilayer cell raises many technological challenges. Not only a high ionic conductivity at room temperature is required to facilitate fast Li-ion transportation and to deliver power, but also controlled engineering of the electrode-electrolyte interfaces and stabilization of high loading cathodes.

Understanding the role of interfaces is a real challenge as it corresponds to the point where the electrochemical reactions occur. It is the strategic place where the electron and ion are meeting, and that permits, this combination of materials, to become a battery.

Towards Li-metal free anodes

The interface must be highly efficient, present a low resistance and should accommodate the different materials. In this sense, and as an example, the lithium metal-solid electrolyte interface should be stable to permit fast electrodeposition (electrostripping) without generating battery-killing dendrites. With an adequate engineering of the interface, our researchers are also developing a lithium metal-free anode (also known as anode-less concept) which is foreseen as a further technological advancement.

The cathode loading is detrimental to the unsure high energy density of the battery and for its competitiveness. While integrating a solid electrolyte inside a cathode electrode, transport issues are arising and are solved by our teams. Our ideal cathode electrode has high ionic and electronic conductivities maintaining active materials´ content at the highest values. We pay extra care that the full capacity of the cathode active material is optimally used.

At CIC energiGUNE, we are taking the lead toward this revolution establishing strategic collaborations with private partnerships and European projects. We are coordinating the ambitious project SAFELiMOVE along with 14 other partners such us Renault, Saft or Toyota to integrate our solid-state electrolyte technology into a 60 Ah demonstrator-pack. We are also a key participant in SUBLIME project in which sulfide solid-state batteries are developed. Not only research and development matter to us as illustrates our participation in IMAGE in which we define the production roadmap towards solid-state battery industrialization at a European level. We even developed highly energy-efficient solid-state batteries, within the framework of the MONBASA project, to be used in space for small satellites.

We are and we will stay active at European initiatives such as Batteries Europe and Batteries 2030 to make our technology stronger and closer to the end-user.

In summary, in order to meet the requirements of the electric vehicle industry for safe, high energy density and low-cost batteries, it is necessary to bet on high-performance solid-state batteries. At CIC energiGUNE, we are dedicated to make a reality the total decarbonization that all European organizations demand.