In December of 1962, a young Ph.D. student, John S. Newman, published the article Theoretical Analysis of Current Distribution in Porous Electrodes. Maybe thinking that it will be like any other average paper… maybe without knowing that this mathematical model for a battery electrode will become the basement for sixty years of electrochemical modelling. However, that article was very far from the current predictive computational models or the modern concept of Digital Twin, considering that the most powerful computer at that time had the equivalent of 96 KB of RAM and 576 KB of storage.

From the lead-acid battery, invented in 1859, to the first Lithium-ion battery in 1991, the development of rechargeable batteries has mainly been driven by trial-and-error experimental approaches. Thanks to the high potential offered by these new devices, rechargeable batteries penetrated in the market very fast, without the need for a deep theoretical understanding of their operation principles. This situation has started to change during the last decade and nowadays multiscale modelling has become one of the main actors in the rechargeable batteries R&D.

In the domain of battery modelling, there is a big family of computational models, such as equivalent circuits, volume averaged, mesoscale, and atomistic models, among others. Each of of them address different physical phenomena at different length scales. In particular, acting as a bridge between the macro and micro scales, we find the so-called mesoscale level models. With a resolution of tens of micrometres, mesoscale models are able to account for the influence of the spatial heterogeneity of the phases constituting the battery electrodes, i.e., active materials, conductive additives, binders, and pores.

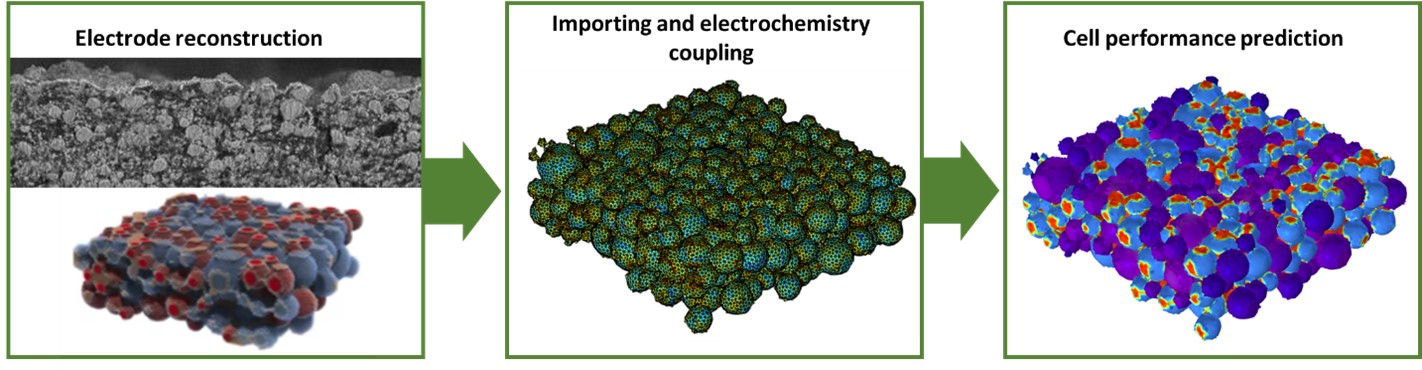

The workflow of mesoscale modelling is the following. In a first step, a fully resolved electrode structure is needed, i.e., a 3D representation of all the previously mentioned phases. This is a critical step because obtaining structural models that reliably represent the properties of the real electrodes is key in order for them to have any predictive power. The electrode structures can be obtained from micro-computed tomography experiments or generated in-silico, using stochastic algorithms, manufacturing simulations, or machine learning.

These structures are then imported into the simulator and, after the implementation of the electrochemical equations for each of the domains that represent the abovementioned electrode components, simulations are performed using numerical solvers. The mathematical models that are used consist of a 3D extension of the original formalism developed by Newman and co-workers.

What is the added value of a detailed mesoscale model?

Mesoscale model is crucial for a better understanding of the working principles of a battery at the level of the electrode structure. The main contributions of this kind of models in the field are:

- Realistic and accurate representation of the electrode. Both using tomography data or experiment-based electrode reconstruction, is it possible to predict the behaviour of a real battery cell under different operational conditions, thus saving time and resources.

- It allows a direct study of electrode heterogeneity influence on the final battery performance. While averaged or surrogate modelling can provide a very fast validation tool for the electrochemical behaviour of rechargeable batteries, mesoscale modelling is used for predicting the influence of the electrode structure in the battery performance, helping to a better understanding of the working mechanisms of the electrochemical behaviour.

- Mesoscale modelling has the capability to predict the influence of the electrode formulation in the battery performance. It means that, playing with the electrode composition, it provides a computational tool for proposing improvements in the electrode fabrication and paving the way towards rational battery design.

- It is possible to estimate observables which are difficult or impossible to measure with experiments. Spatial distribution of lithium concentration in the active materials, synergy between different active materials in blended electrodes or the current distribution on the electrode surface helps to understand the cell electrochemistry optimizing the experimental testing.

Challenges

Some of the challenges that mesoscale modelling needs to address are:

- During several years the computing time was the main limitation for the mesoscale modelling, nevertheless this trend is slowly changing, and while it is still far from being applicable for any real-time battery diagnosis system, thanks to the increasing computing power together with the optimization of numerical solvers and it is possible to simulate a full charge or discharge in a couple of minutes using a desktop computer.

- The electrode reconstruction remains a real challenge. The access to electrode imaging is limited to few research institutions and the reconstruction techniques are for the moment inaccurate to capture all the details of a real electrode mesostructure. However, significant progress is being achieved in the imaging techniques using artificial intelligence. On the other hand, there are available libraries for image reconstruction free of access, making these techniques more accessible to the scientific community.

- The computational modelling of the degradation mechanisms, like solid-electrolyte interface, dendrite formation or active material fracture is still in the infant stage, mostly due to the need of a better understanding of the electrochemical and mechanical processes at the microscopic scale in order to find a predictive model for these mechanisms. Nonetheless, there is a big effort in the scientific community from both, the experimental and computational approaches for the development of this research line.

In short. Electrochemical modelling has recently become a main actor in the R&D of rechargeable batteries. Together with the increase in the computing power, fully resolved 3D electrochemical models have demonstrated during the past few years to have the capability of providing a rational understanding of the working mechanisms of a battery. In addition, the battery performance prediction is a reality nowadays and allows to guide experimental research, reducing time, environmental impact and economic costs.

Here at CIC energiGUNE, we are working in the development of multiscale models of rechargeable batteries, leveraging the capabilities of our research team to perform electronic structure, molecular dynamics, mesoscale and macroscale simulations on a wide variety of interesting systems for battery research. This gives an added value to the cooperative spirit of the center and to the competitiveness of Basque industry.