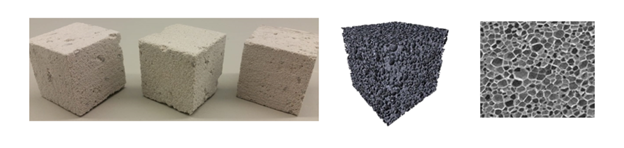

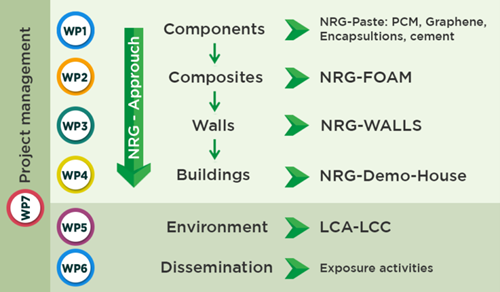

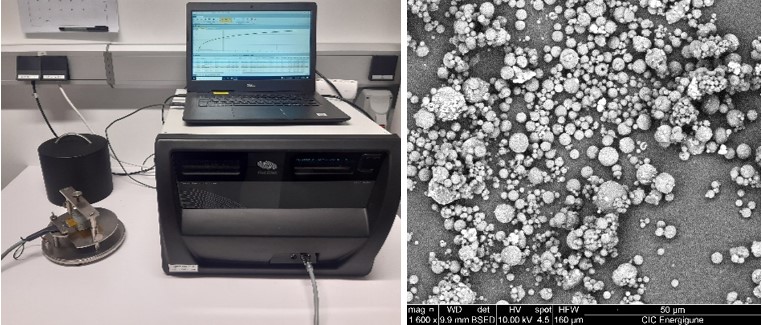

NRG-Foam composites are designed to achieve the best compromise between thermal insulating properties and heat storage capacity by incorporating Microencapsulated bio-based Phase Change Materials (bio-MPCMs) in the initial cement paste.

In addition, graphene-based nano-additives, added to both cementitious foam matrix and MPCMs fraction help to improve the composite mechanical properties and to reduce the hardening shrinkage phenomena and associated ageing effects.

Improvements in the energy storage capacity of the foam will also be achieved through two active systems which will work together in an optimized configuration as: (i) an active system at the material scale level, triggering the PCM melting by the electrical activation of the embedded graphene; and (ii) an active external full-scale system, developed in a previous EU project, which will recover the storage capacity of the envelope by re-solidifying the melted PCMs.

These complementary systems will be optimized to have the best performance among the three different climatic conditions (mediterranean, oceanic and humid continental) chosen as a reference for the demonstration sites. In this context, an improvement of, at least, 15% in energy-storage capability than actual solutions has been confirmed by preliminary simulations.

The project will ultimately contribute to the fast-growing market of building envelopes, for both retrofitting and newly built objects, by implementing the TRL levels 5 to 7 of the next generation of prefabricated NRG-Foam insulation material.

The proposed product aims to comply with a more than 25% improved insulation capacity, more than 10% higher energy-storage capacity, at least 10% higher water and air tightness, and less than 15% cost increase than the existing solutions based on synthetic materials, glass fibers or stone wools.

This highly efficient and sustainable solution also shows a reduced layer thickness (50% thinner than EPS), a non-flammability, a very low CO2 footprint, a non-toxicity, acoustic insulation/absorption capabilities, dimensional stability, without affecting the indoor air quality and it is easily recyclable.

Finally, the proposed NRG-Foam can be produced as prefabricated panels, with minimum manufacturing and installation costs, allowing its use in new buildings and for retrofitting purposes.

To reach these ambitious goals, the NRG-STORAGE project is based on a multidisciplinary consortium of 13 partners.