INTRODUCTION

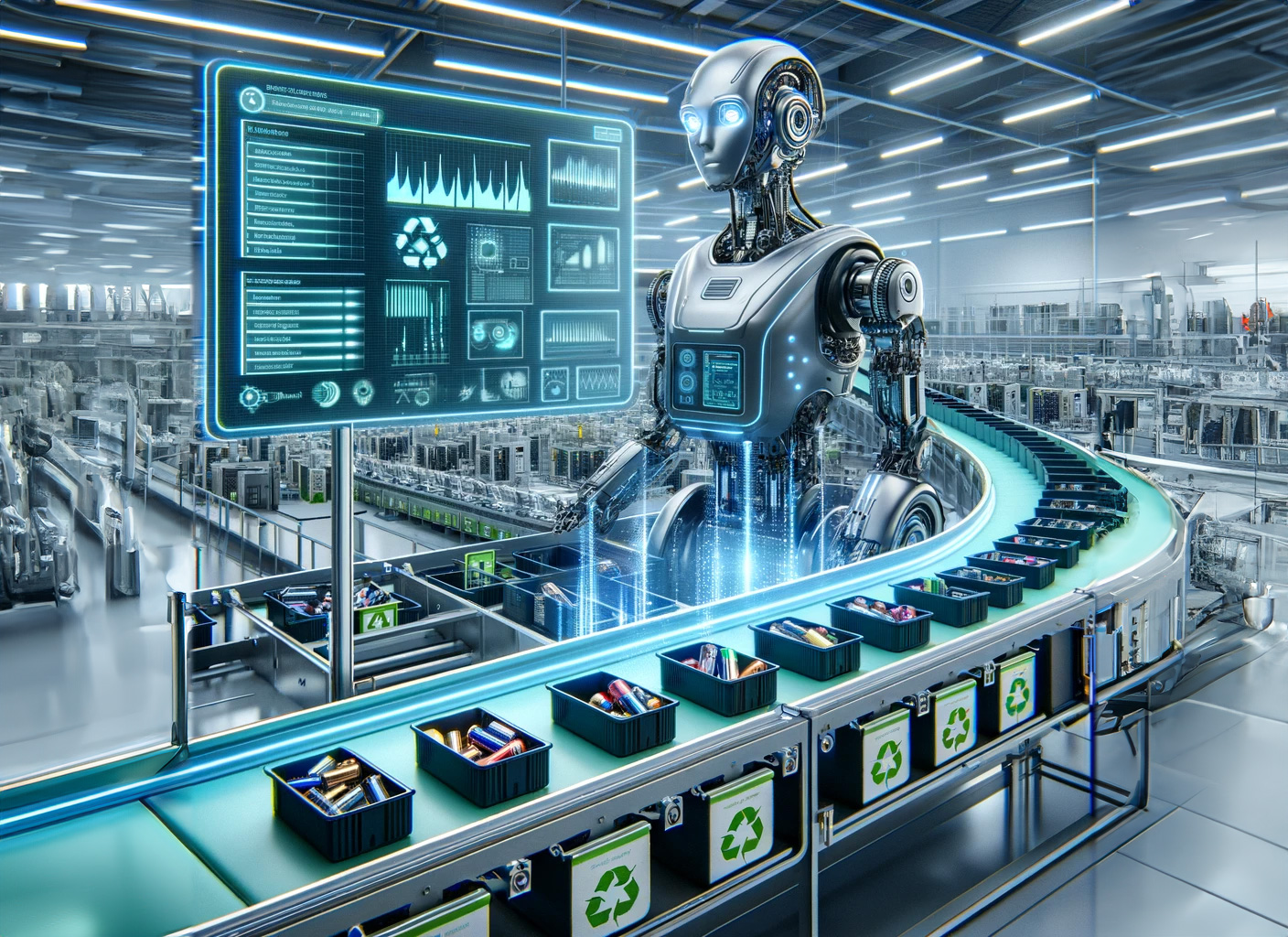

Due to the expected demand in the battery sector in the coming years, the industry´s efforts are focused on the technological evolution of the different stages of the value chain, such as, for example, the recycling of these devices at the end of their useful life.

This phase is a critical activity, since its deployment will determine whether the industry is truly "circular" and meets the expectations of the sector in terms of competitiveness, guarantee of supply and sustainability.

For all these reasons, it is necessary that the technological recycling routes that are developed are profitable, industrializable and sustainable; achieving, quickly and efficiently, the necessary economies of scale to ensure the viability of the activity.

Hence the importance of taking advantage of the new approaches that digitalization and the solutions that compose it (such as Artificial Intelligence, also known as AI) can offer to battery recycling plants, with the corresponding advantages that in terms of time, cost and efficiency present this type of tools.

This document makes a high-level identification of this set of opportunities presented by AI for the two main activities that make up the recycling of this type of devices: on the one hand, the management of waste once the useful life of the battery is over and, on the other hand, the recovery of materials from these wastes through the different existing technological routes.

|

Two main stages in the battery recycling process |

||

|

Phase 1 Waste sorting |

Phase 2 Recovery of materials |

|

|

Description |

Initial stage aimed at classifying existing waste in order to identify potentially recoverable waste and materials. |

Treatment stage of previously sorted waste, in order to recover the available materials through the different existing technological routes. |

|

Summary of opportunities presented by AI |

|

|

Table 1: Summary of phases of the battery recycling process and potential opportunities for AI in these phases.

POTENTIAL OF THE AI IN THE FIRST STAGE OF WASTE CLASSIFICATION

As indicated above, the battery recycling activity starts with a first phase associated with the classification of waste in order to identify which waste and materials are potentially recoverable.

With this objective, this first initial stage can count on a great ally in AI, offering, through its different algorithms, very useful pattern recognition solutions in this phase of categorization and grouping of the different wastes. All this, with the added benefit of enabling a higher degree of safety in waste treatment, as we will see below.

In relation to the classification capacity, there are studies [1] that have shown how, through image recognition techniques, the AI is able to determine the location and type of waste to be treated. This makes it possible to determine which method or route may be the best for "managing" that waste according to its nature (taking into account, for example, aspects such as its toxicity or other key aspects associated with safety in its handling). All this not only results in greater efficiency in waste classification, but also reduces the risk associated with the process by selecting the most optimal one.

This first categorization is complemented by the possibility of automating the process of grouping waste into "batches", performing the corresponding groupings according to their characteristics in order to unify their subsequent treatment and recovery. In this case, there are approaches [2] that have demonstrated the use of convolutional neural networks for this purpose, which allow, from a sufficient set of labeled data, to perform this grouping. It is also expected that this categorization capacity will be increased and polished as the number of data and references available to the AI for this purpose increases, through approaches such as those proposed by A. Abucide-Armas et al [3] and Azurmendi et al [4].

Beyond these advantages, another key element of the use of AI in this phase of the process is the ability to capture data to predict the potential amount of waste to be treated (for which it is key that they work in real time [5] [6]). This involves planning the activity in advance (determining and optimizing possible recycling routes), and quantifying how much material can be recovered for subsequent reuse in new batteries.