In order to be used in second-life applications, these batteries need to go through different stages and processes. These may depend on the level of dismantling (pack, module, cell or components) that is nowadays manually performed due to the lack of regulatory framework. It is also recommended to have the battery totally discharged for safe handling.

Finally, regarding disassembling – assembling, it is also necessary to consider that the cell comes in three different formats (cylindrical, pouch and prismatic) where each type have is one specificity. Therefore, the all-reconditioning process will require a highly qualified workforce and set off knowledge.

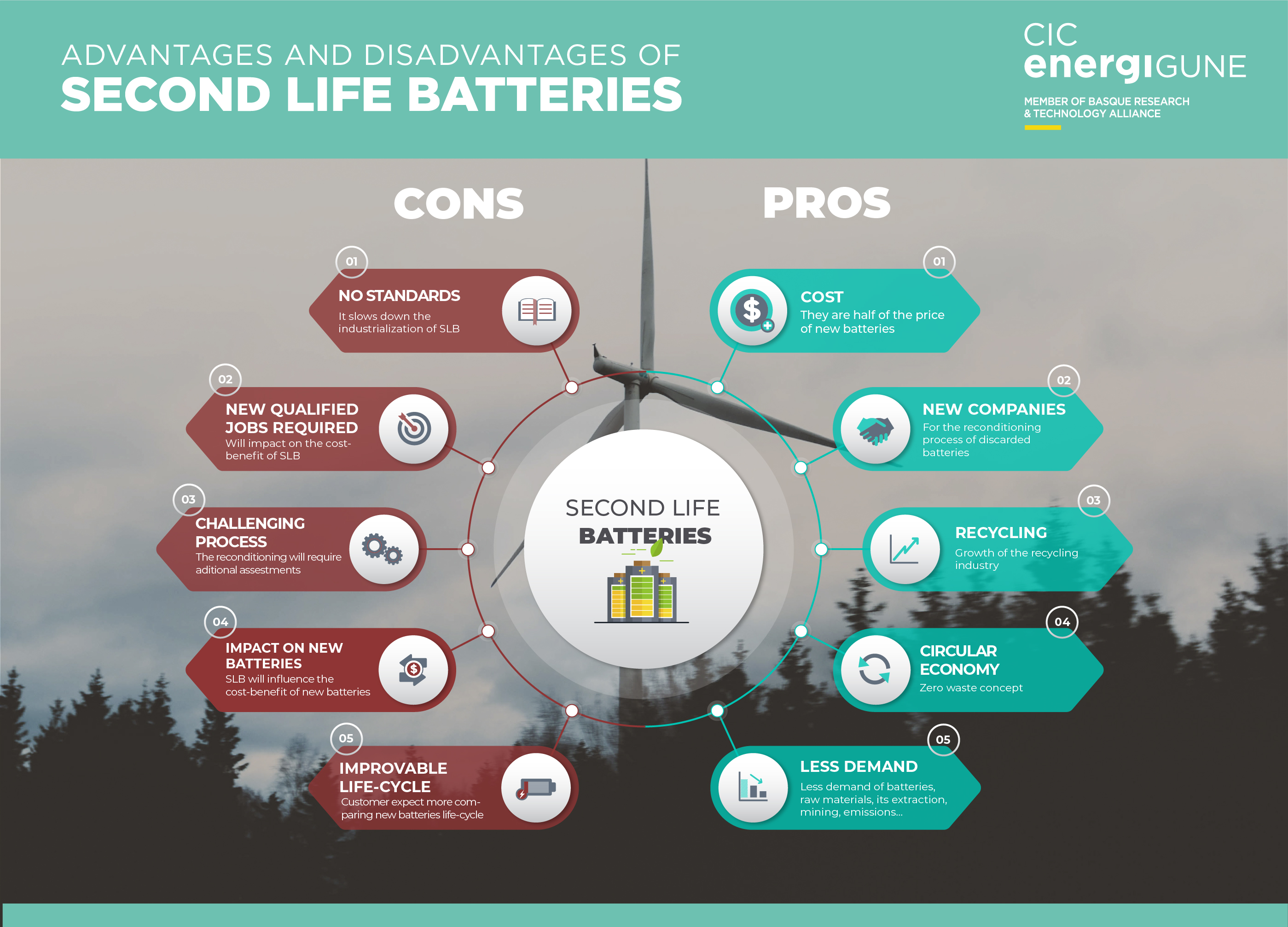

Advantages of Second Life Batteries

Despite all these additional steps, some study previsions have evaluated the cost of Second-Life Batteries might be half of the price of fresh batteries and potentially provide substantial financial opportunities for individuals and companies that in fine will help to reduce the cost of EV battery. Furthermore, new companies could be created that will take charge of the reconditioning process of the discarded batteries.

Second, the market of SLB in stationary applications could also benefit from cheaper solutions for their Electrochemical Energy Storage (EES). Finally, the recycling industry could also take advantage of batteries that don’t reach the requirements of the SLB application.

Apart from the economic perspective, the use of SLB will also have an impact from an environmental point of view. The concept of Zero waste management is applied by using SLB to prevent the creation of waste as well as to reach the circular economy. Besides, the use of Second-Life Batteries to Electrochemical Energy Storage for stationary applications will extend the life cycle of the battery.

The additional environmental benefit is the impact of reduced demand for new batteries. Therefore, the gross energy demand will be decreased, as will global warming by potentially 15-70%. Also, lower demand for new batteries will reduce the need for raw materials, the environmentally harmful materials extraction process, water for mining, CO2 emission and electricity for cell fabrication.

Challenges of Second Life Batteries

Notwithstanding the potentials advantages of the SLB, the implementation needs to overcome some obstacles and challenges:

Regarding implementation, standards and automatization will speed up their industrialization, having a positive contribution in terms of safety and cost. As explained earlier, the dismantling process will require highly qualified professionals that can have an impact on the cost-benefit of SLB.

In addition, the battery comes in different shapes and forms together with different voltages and chemistries. This is a real challenge for the reconditioning process and might require additional assessment. Thus, it can further increase the reconditioning cost.

In that context, finding a similar cell and matching the good battery together is an important factor for the performance and lifespan of SLB. The commitment is that the full implementation of the SLB impacts the price of new li-ion batteries and their cost-benefit balance positively.

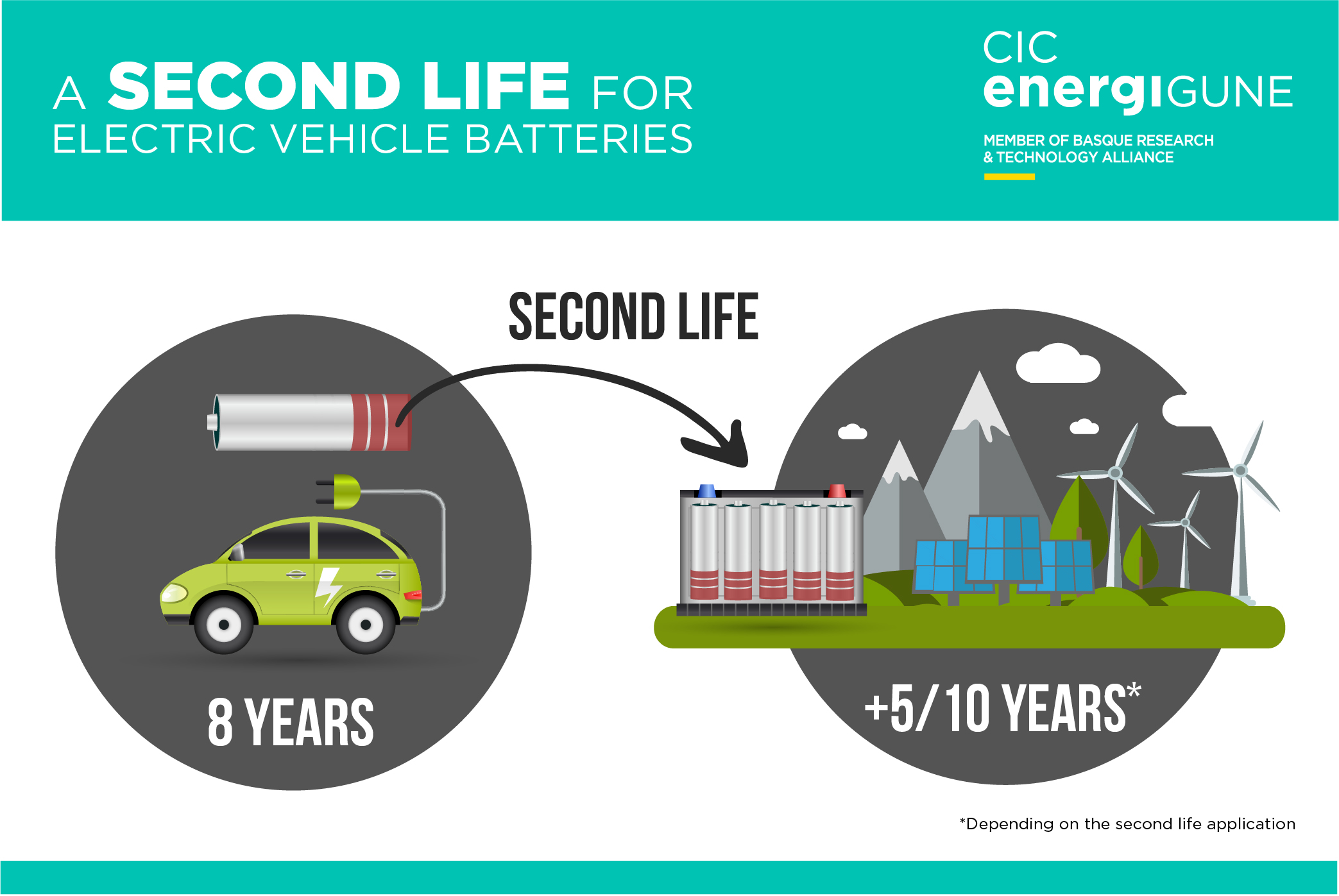

In addition to that, the critical challenge is to extend the life cycle of these SLB more than 5-10 years in response to what the customer may have in mind compared to new batteries.

In that sense, an ally is the accurate measurement of SOH and RUL, as advanced predictive models may give precise information about the remaining life of the cells for an SLB application.