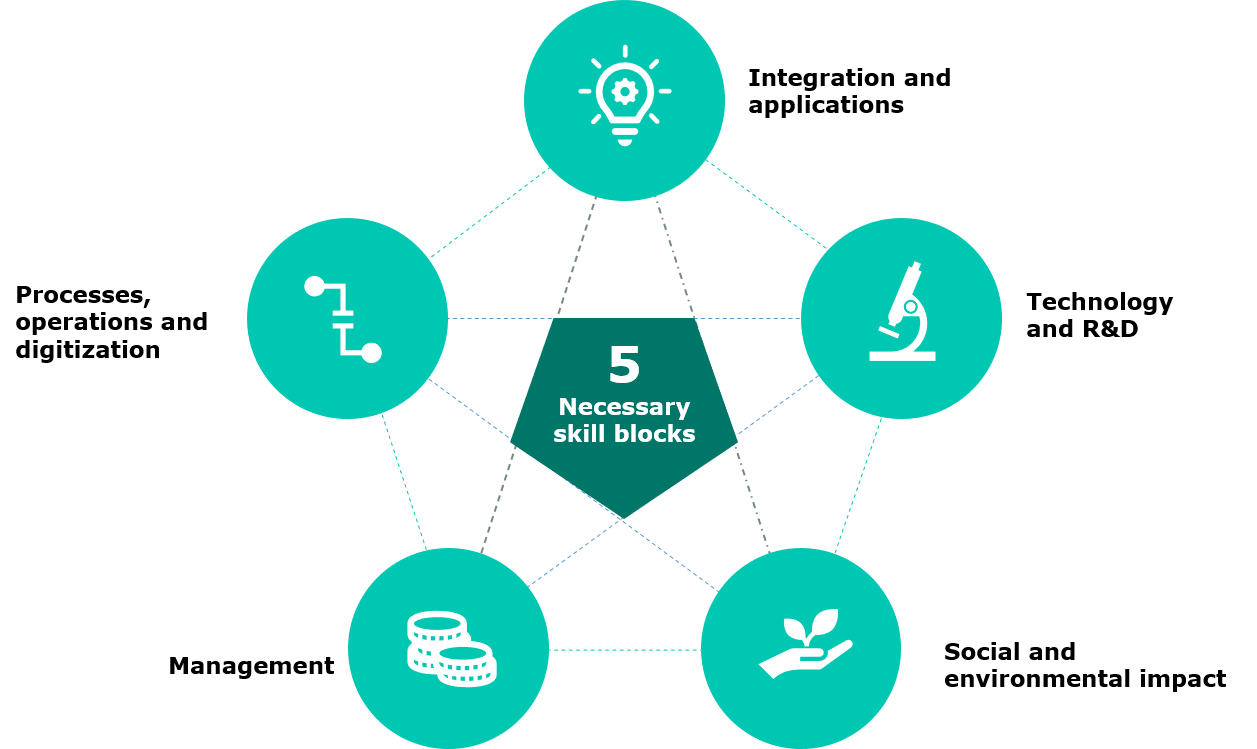

- Integration and applications:Includes those profiles associated with the development and identification of solutions to implement in the different applications / needs identified in the battery market.

- Processes, operations and digitization: Includes those activities related to the development and implementation of processes and operational activities to be developed within the value chain and continuous improvement processes linked especially to digitization.

- Technology and R&D: Includes those jobs and activities associated with the technological and scientific development of the value chain.

- Management:Composed of profiles linked to the management, from an economic, legal, human, etc., point of view, of the different activities included.

- Social and environmental impact: Contains those profiles and activities associated with the effect of the value chain stages on its environment.

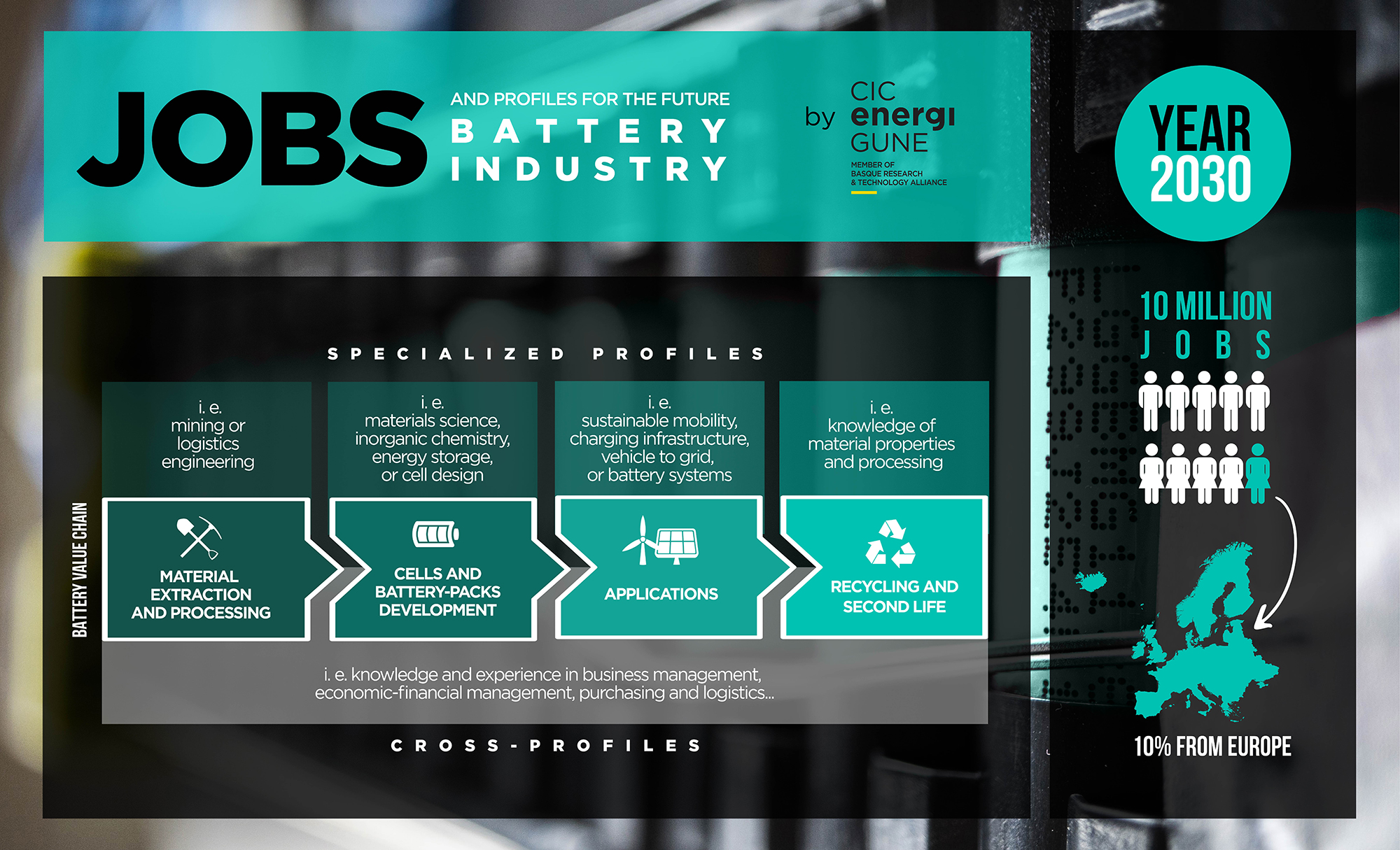

Variety of positions and profiles depending on the value chain stage

For each stage of the value chain, it is expected that, in one way or another, these profiles and skills will be represented through the activities to be developed and the jobs linked to them.

Thus, going into detail, we can find the following specialized profiles according to the stage of the value chain, as well as those "common" ones that all of them will need for their proper functioning:

A) Specialized profiles

Within this typology, we can highlight the following profiles at a high level:

1º Materials extraction and treatment

As this is the stage associated with obtaining and preparing the raw materials necessary for battery production, it includes profiles with a high technical aspect associated with extracting materials and their treatment.

Thus, degrees such as mining or logistics engineers will be in demand to cover this first part of the battery value chain. Likewise, the need to refine and purify these materials will require specialized profiles in both chemical and physical processes.

2º Development of cells and battery packs

Within this second stage, the technical profiles in demand are much more closely linked to the electrochemical branch, as this is the phase in which the cells and packs that makeup batteries are produced.

Thus, specializations associated with materials science, inorganic chemistry, energy storage or cell and pack design will meet the profile needs of this second stage.

Likewise, since these are production processes, training related to the implementation of production processes, their scaling and continuous improvement will also play a significant role.

3º Applications

In this case, the use of the different batteries determines the type of specialized profiles required at this stage. Thus, the knowledge required will vary depending on whether we are talking about electric vehicles, stationary applications or other uses such as, for example, construction (buildings or production plants).

Focusing on the first two cases, electric vehicle applications will require professionals in fields related precisely to these means of transport. In other words, technical profiles with knowledge of the fundamentals of each vehicle (cars, heavy transport, trains...) will be needed to complement this knowledge with the application of batteries in these industries.

Thus, professionals with training or experience in sustainable mobility, development of charging infrastructures, vehicle to grid, battery systems or diagnosis and repair will be highly demanded in the future concerning this use.

In the same way, stationary uses will also demand profiles that can combine both knowledge in energy storage and each energy source to which the batteries would be associated (mainly solar and wind energy). Along with them, professionals with knowledge in control and optimization of systems will also be needed to supervise the management of this stored energy and its access to the grid.

4º Recycling and second life

Finally, in this last stage, the profiles associated with the electrochemical and materials branches become essential again. The reason is that, once again, the management of the resources used to make batteries comes into play, in this case, intending to recover these materials, giving them a new life or treating them appropriately for their use in other applications.

Therefore, this stage requires professionals with knowledge of material properties and their processing to be able to carry out the chemical recovery of these resources (either for recycling or for a second life).

In addition, it will be necessary to have profiles with knowledge in materials separation technologies and processes (both hydrometallurgical and pyrometallurgical and new advances that may arise).

B) Common profiles

As indicated at the beginning of this section, all this specific knowledge required by the different stages of the value chain will be accompanied by another series of "cross" profiles, common to all of them, which will complement the set of skills necessary for the correct operation of each one.

On the one hand, we find profiles related to the management of the "business" of each of the stages. Thus, professionals with knowledge and experience in business models, economic-financial management, purchasing and logistics... will be necessary for the proper functioning of each activity.

Likewise, another profile that becomes very important in all stages of the chain are those professionals with experience in environmental impact assessment, both from a technical point of view (such as, for example, environmental engineers capable of measuring and managing environmental impact through LCA techniques) and regulatory (associated with legal profiles capable of analyzing the impact of environmental policies).

In addition, the preparation and knowledge of fields such as modeling, simulation or optimization based on data science will also be highly valued in the different stages, as they will be able to base the corresponding research and development on them to improve the activities carried out.

Finally, other professionals such as those responsible for logistics, processes, continuous improvement, safety and risk or quality will be needed to complete the puzzle of skills and knowledge that this value chain will require.

The upcoming training

Due to this high demand for jobs and qualifications that the sector is expected to generate in the coming years, different European countries and initiatives have been launched to train the future professionals.

In this sense, one of the most outstanding initiatives is the one recently launched by the "European Battery Alliance" (EBA), known as the "European Battery Academy Academy".

This program, which will soon be launched in countries such as Spain and France, seeks to train European workers in industrial battery and electric vehicle manufacturing projects.

There are also other initiatives at European and national level aimed at training and future qualifying professionals to meet the needs of the energy storage value chain. One of the most outstanding is the MESC+ program in which CIC energiGUNE collaborates and where large companies in the sector such as BOSCH, UMICORE, RENAULT or EDF also participate.

In short, as can be seen from these examples, the battery sector and its ecosystem has already begun to take its first steps to prepare these profiles of the future, in order to be able to satisfactorily meet the challenges and needs posed by one of the most promising industries of the future, the battery industry.