In inventory or asset tracking such as cold chain in food or medicine, one of the technologies that has emerged in the last decade is radio frequency identification (RFID). These chips or tags are very small devices that can be attached to products, animals and people, and are capable of uniquely identifying "items" without the need for physical or visual contact. In fact, in the last decades it has been replacing the well-known bar codes and magnetic stickers. Commonly, these types of tags are either active or passive, the latter carrying a battery as a power source for the internal circuits. Depending on the different features required of an RFID, its price can be very different, and thus its market penetrability.

For certain applications, the passive tags, cheaper, do not have a good enough reading range to identify the objects you want, but at the same time the semi-passive or active tags, which would give the necessary benefits, are not used because they are too expensive. In particular, semi-passive tags are particularly interesting because they are stronger in the read rate than passive tags and have reliability comparable to that of active tags as well as longer duration without losing operating range. Semi-passive tags use a "reader" to supply the necessary energy to transmit the information, reducing consumption and extending their useful life. The problem is cost, since the semi-passive tags used have a cost up to 180 times higher than the passive ones, which limits their use to applications with high added value products.

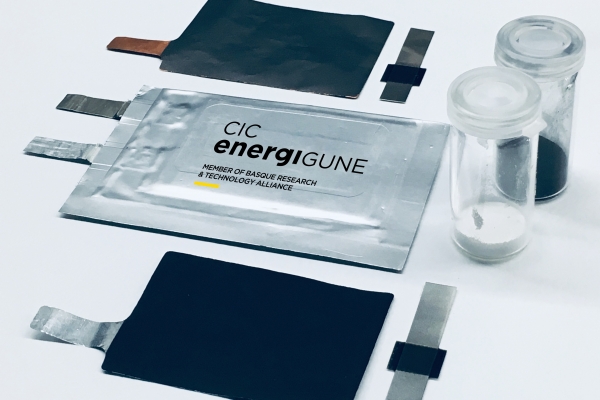

Design and develop a family of low-cost semi-passive tags based on radio frequency identification (RFID) technology. This solution is composed of an integrated circuit (IC) to process and store the information from the associated sensor or sensors, a flexible primary flexible battery miniaturized and embedded in the system, and an antenna to transmit the information to a receiver.

The key to addressing cost, in addition to material selection, would be the development of a device manufacturing line with strategies for optimal component integration.

An economically viable adaptation of the battery components to the complete system has been achieved for correct operation under the established working conditions. In addition, the sealing parameters of the battery have been correctly optimised, which is critical for operation in different temperature and humidity conditions. The flexible battery has a lower cost than the ones known in the market and provides the necessary features for the optimal operation of the semi-passive tag for a wide range of applications.

In addition, a pilot line has been designed to manufacture semi-passive tags with an optimized battery to integrate the components at a competitive cost.

Business Development Manager: businessdev@cicenergigune.com

If you want to know the latest trends in energy storage and new developments in research, subscribe.

If you want to join a top-level team, collaborate with specialists in multiple disciplines or tell us about your concerns, don't think twice...