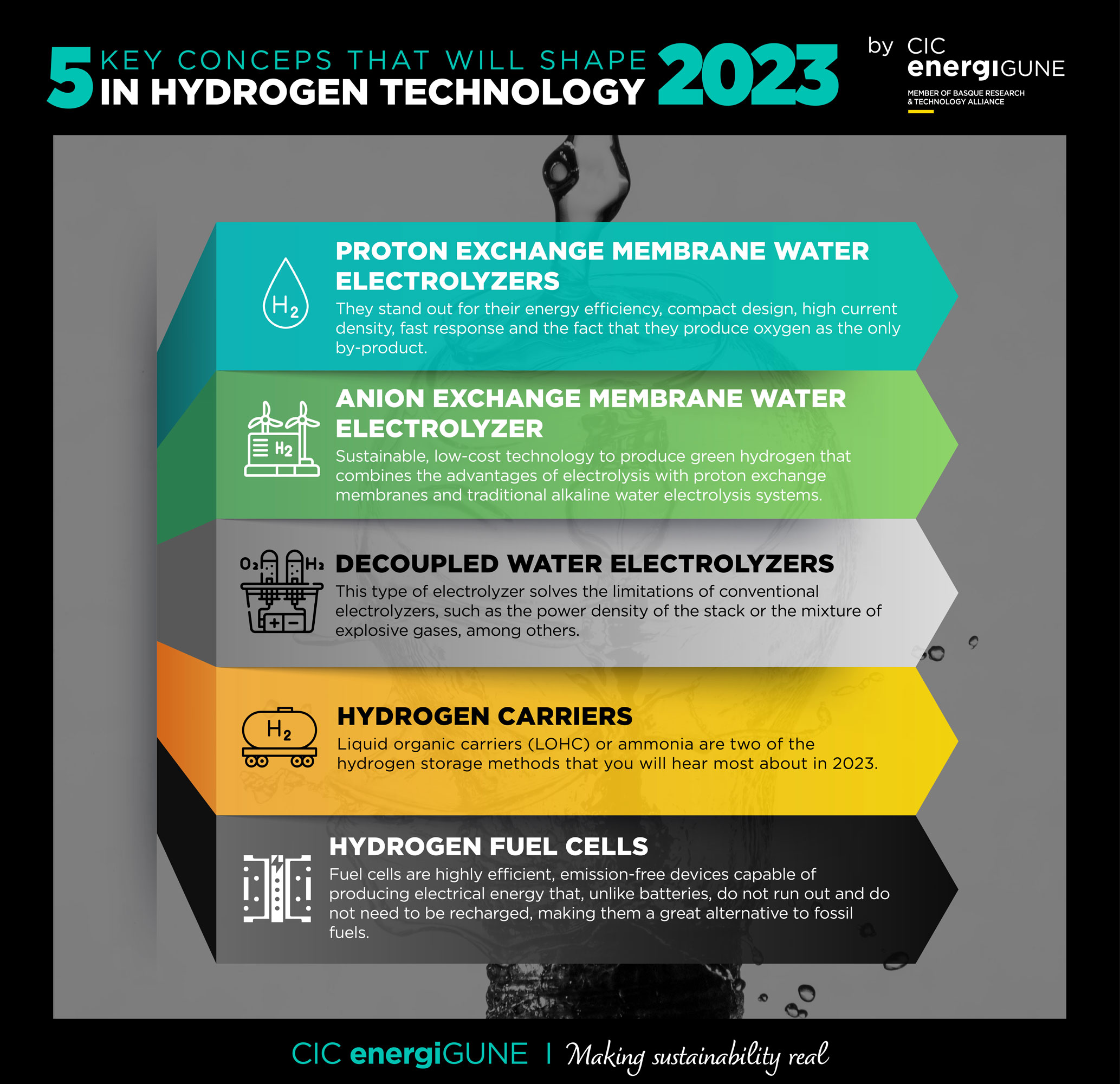

Proton exchange membrane water electrolyzers

Proton exchange membrane (PEM) water electrolyzers are capable of sustainably producing high-purity hydrogen for both chemical and energy storage applications.

These types of electrolyzers have attracted much attention in recent decades due to their energy efficiency, compact design, high current density, fast response and the fact that they produce oxygen as the only by-product.

However, the most popular PEM electrolyzers for hydrogen production by electrolysis are based on precious metals (Pt, Ir, Ru) whose high cost has an impact on the final investment of the PEM electrolyzer. Hence, the latest research is directed towards the search for materials that can reduce the final cost of the technology and thus contribute to the popularization of this promising hydrogen production system.

Anion exchange membrane water electrolyzers

Anion exchange membrane water electrolyzers (AEMWE) are a sustainable, low-cost technology for green hydrogen production that combines the advantages of proton exchange membrane water electrolysis and traditional alkaline water electrolysis systems.

Unlike proton exchange membrane water electrolyzers, the AEMWE uses transition metal catalysts instead of precious metals; in addition, the membrane used in the AEM is less expensive and the titanium of the PEM can be replaced by stainless steel.

Thus, overall, anion exchange membrane water electrolyzers show greater potential as they can produce green hydrogen at a competitive price.

However, it is critical to understand the limiting factors associated with durability that restrict the long-term use of these devices, as the membranes used turn out not to be durable in industrial environments.

Hence, research in 2023 will focus on improving the long-term efficiency of the membranes of this technology.