Regarding the European battery manufacturing strategy, recently the 2006 EU regulatory framework of batteries was revised. New carbon footprint rules, a minimum recycled content, performance and durability criteria, end-of-life management requirements, due diligence obligations, or safety and labelling (e.g., QR for battery passport) requirements were set. These kind of regulations will allow to develop not only batteries with good performance, but also those that will kept the sustainability of the technology. As the batteries of the future will not be those that performs better, but those that are able to keep the performance and sustainability well-balanced.

Artificial Intelligence

Nevertheless, cost and safety are still the major concerns of the EV in our society. One of the key points to reduce the cost of the battery manufacturing and later implementation in the EV, comes across the Artificial Intelligence (AI). It is known that will play an important role in our early future, as it is able to accelerate human discoveries in a 5-10-fold rate increase.

In this regard, under the Battery 2030+ initiative, BIG-MAP project, where CIC energiGUNE takes part through the FullProfApp tool, already works on AI in order to accelerate the discovery of new materials, electrolyte/electrode interphases or materials’ formulation among others, to boost the cell production and their integration in the EVs.

Digital Twins

Meanwhile, digital twins of manufacturing processes, being a virtual replica of an actual physical and complex system, will also play a significant role on the better understanding and optimization of physical parameters and processes, predict, and understand malfunctions of the equipment’s. Specifically, digital twins of the EV, will allow to predict why and how problems such as breakdowns occur, or will analyse the overall vehicle performance allowing to deliver a personalized service to the customer.

Electrode processing

Another aspect on battery manufacturing that will reduce the cost of batteries and make them more sustainable is focused on the electrode processing. The necessity of moving from toxic organic solvents towards aqueous or solvent-free processing has become of major importance. As it will allow to reduce the energy consumption along the battery manufacturing and to move towards more sustainable processes. Among different active projects on this topic, GIGAGREEN was recently granted by the EU commission, where CIC energiGUNE leads the wet and dry processing pathways development activities.

Safety

One of the main points discussed regarding the improvement on safety was to focus on battery sensoring. Under the Battery 2030+ initiative, different projects such as Sensibat, Spartacus or Instabat are already working on that. BCare, the spin-off of CIC energiGUNE also works to maximise the device performances by diagnosis and prediction of health, and fault identification and analysis by the introduction of sensors in the cells. Furthermore, introducing self-healing processes in batteries, as made in the projects of Hidden or Bat4Ever under Battery 2030+ initiative, can also ensure the fabrication of safer, and longer-lasting batteries.

Communication between Academia and Industry

Despite the challenges across cost and safety, from the perspective of the Young Scientists, we need to improve communication between Academia and Industry. Cooperation can help to bridge the gap between fundamental scientific research and industry demand, which is of key importance to achieve high-impact battery development. Certainly, industry needs the fundamental insights arising from academic research, while academia would strongly benefit from industrial feedback to guide future research paths.

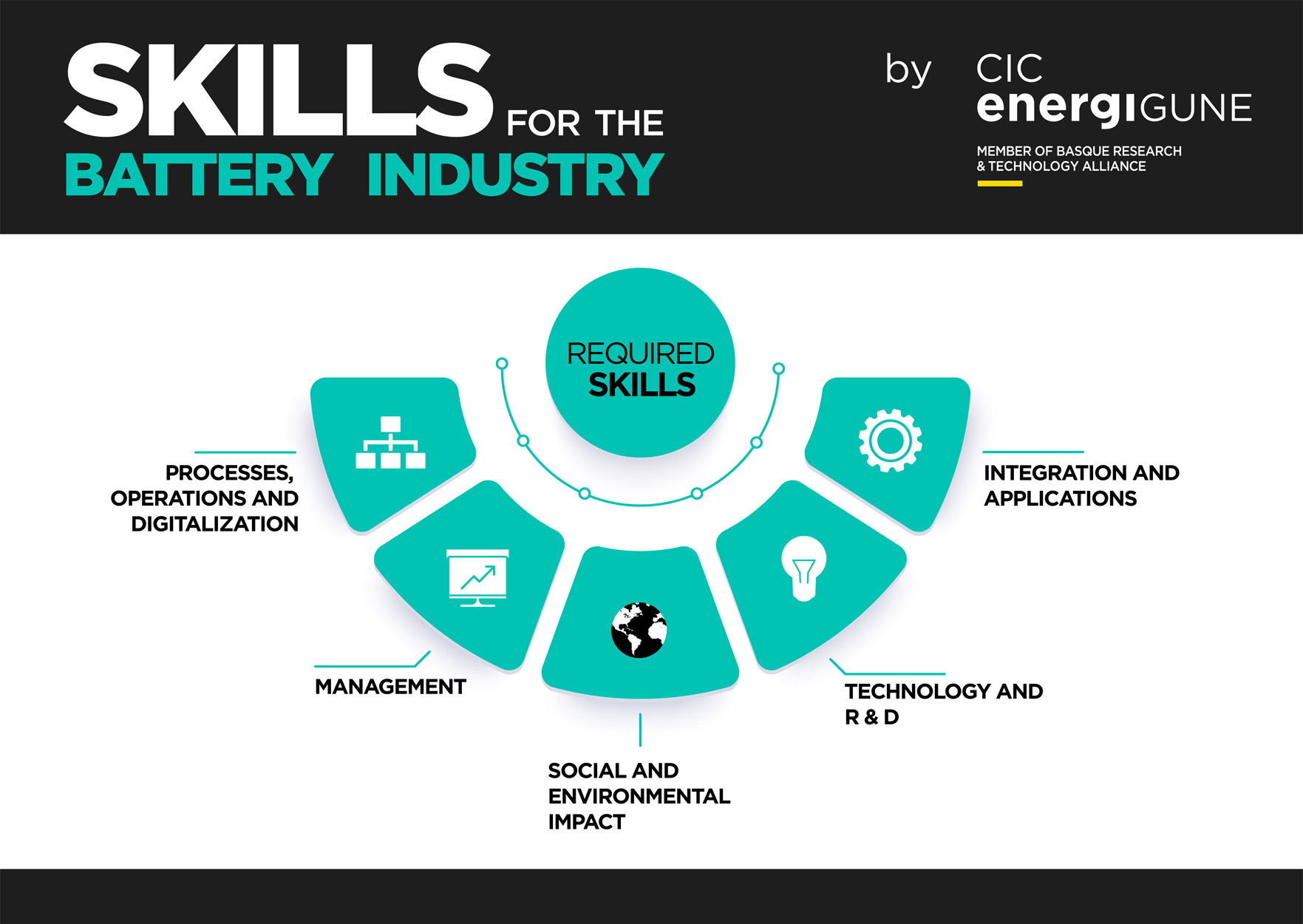

Multidisciplinary teams

Moreover, in the last and most innovative steps defined towards the batteries of the future, the necessity of gathering researchers from different fields has been identified. Creating multidisciplinary teams for the battery production, research and innovation, and recycling industries could make use of already existing scientific and other human resources from other sectors and provide new innovative perspectives on the field of batteries, covering the knowledge along the whole battery value chain.