WHAT ARE THE CHALLENGES TO ACHIEVE THIS MODEL?

In view of these perspectives and advantages, the industry is working to respond to two of the major challenges posed by the widespread implementation of this model within the industry.

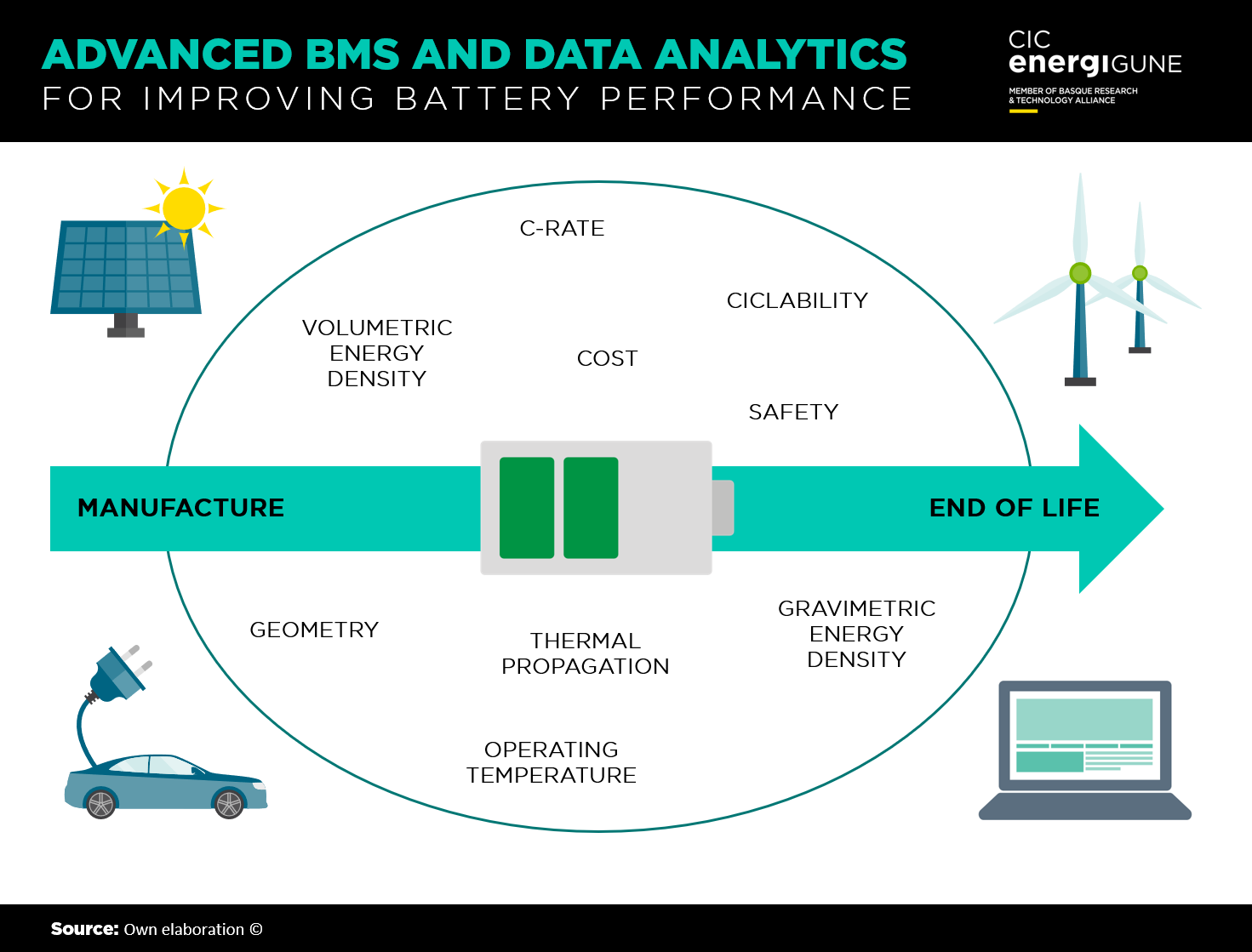

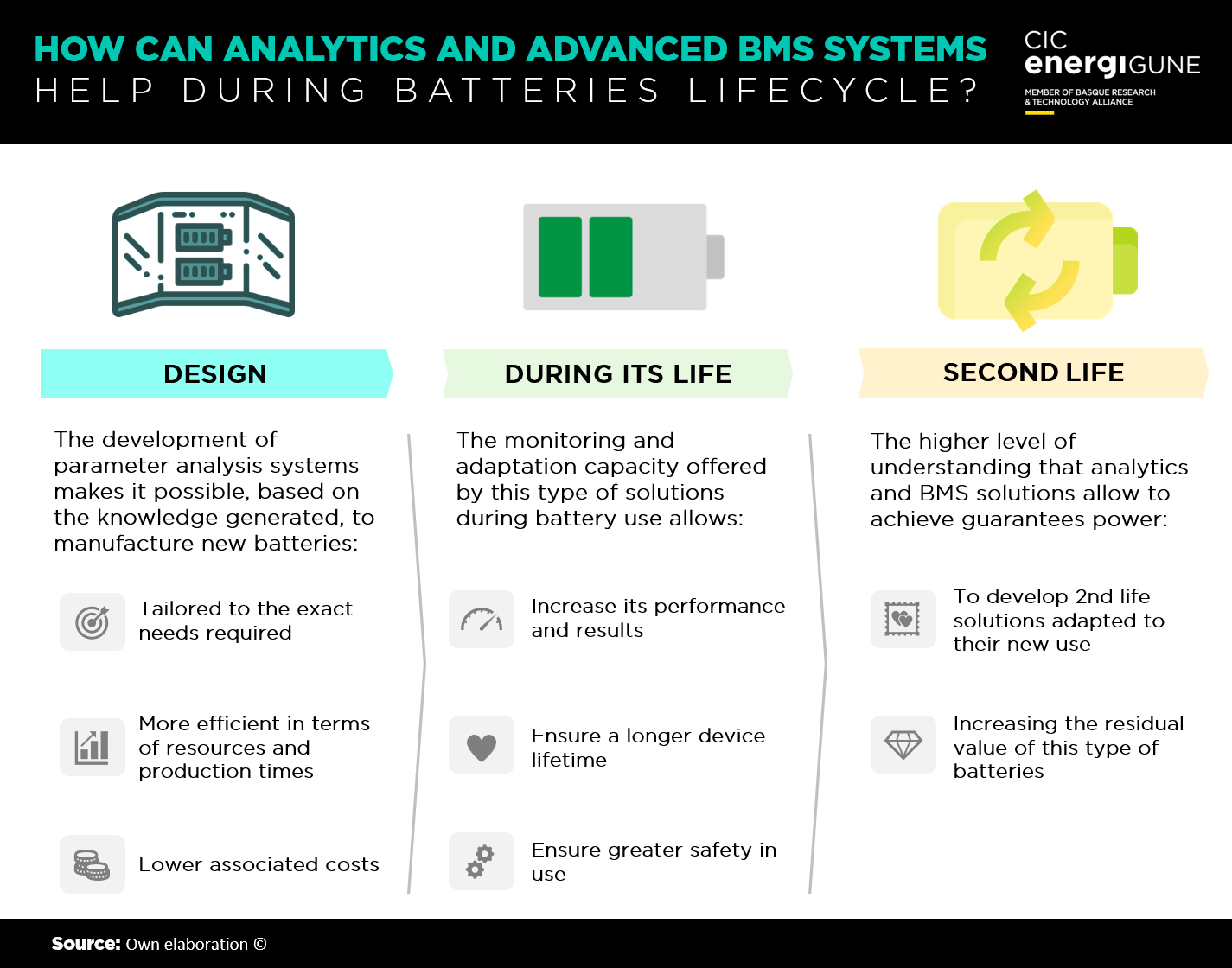

The first of these, and perhaps the most pressing, is to develop BMS systems that have the appropriate software to capture and exploit information.

It must be taken into account that the BMS itself is a "base" device that exists in all batteries to ensure their correct operation in terms of safety and performance. Hence, it needs the incorporation of new software solutions that allow it to go beyond the current state of the art, making this system a real "brain" that not only manages the information, but is able to "understand" it and get, through the system, the most out of it.

In addition, the other major challenge for the coming years is the development of advanced BMS capable of adapting to any generation of batteries. In other words, this type of solution should advance at the same pace as the energy storage technology itself, being able to adapt to different configurations, chemistries or approaches (such as those based on solid state).

In this sense, there are already different agents in the market that are working to promote this type of solutions. Large companies such as Bosch, Intel, Panasonic or Continental are working to develop new advanced BMS technologies based on data analytics, as are start-ups like Brill Power and Novo.

These are only international examples, but there is no need to go that far to find companies that are committed to the development of this type of key solutions to boost the energy storage industry. An example of this is Bcare (first spin-off of CIC energiGUNE) that offers today in the market different solutions and products aimed at maximizing the life of the batteries, anticipating the various incidents and problems that may present any storage system.

All this, with the support of CIC energiGUNE itself, which is also working on the development of new solutions and approaches to deepen the knowledge on battery management and its modeling and simulation based on new technologies.

In conclusion, we can see once again how key sectors for the future (such as batteries) can also boost the application and use of new digital innovations (such as big data and data analytics), taking advantage of the range of opportunities they offer. Hence, as we have previously analyzed in our blog, it is said that the commitment to the energy transition goes beyond sustainability, and is also a way to accelerate technological and digital development that will have a positive impact on our environment and society.