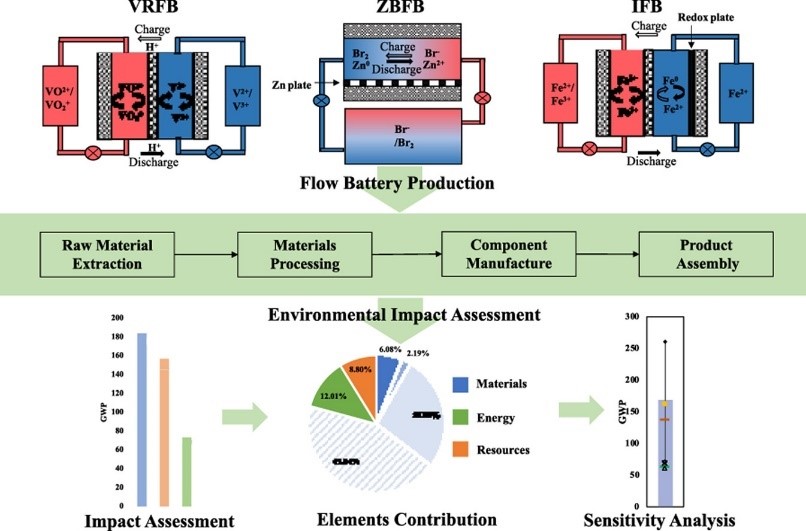

Their ability to decouple power and energy makes them a suitable option for grid-scale stationary applications in terms of scalability, moderate maintenance cost and recyclability. In addition, these batteries based on highly stable redox active materials have a long cycle life (>10,000 cycles) and calendar life (10-20 years), as components can be replaced independently.

The European Union´s commitment to sustainability

The battery industry in Europe is undergoing an important process of evolution aimed at achieving compliance with the European Commission´s proposed amendment to the regulation on batteries and battery waste, repealing the Directive 2006/66/EC and amending the Regulation (EU) No. 2019/1020. The ultimate goal is to ensure that batteries placed on the EU market are sustainable, high-performing and safe throughout their entire life cycle.

Since the launch of the European Battery Alliance, EBA250, in 2017, stakeholders along the value chain have called for this regulation as an important tool to build a truly sustainable European battery industry that supports Europe´s transition to electrification. Thus arises the battery passport whereby from January 1, 2026 every industrial and electric vehicle battery placed on the market or into service whose capacity exceeds 2 kWh must have an electronic registration, which "shall be unique for each battery and identified by a single identifier," according to the regulatory language itself.

The redox flow battery sector driven by the recently created FLOW BATTERIES EUROPE, which was created to set up a long-term strategy for this sector, has included in its roadmap to comply with the sustainability criteria required for their use, not forgetting the equally necessary technical and cost requirements.

The environmental impact of redox flow batteries, as with other batteries, depends on the components used as raw materials, the associated manufacturing process, their lifetime and end of life, in other words, their life cycle.

Life cycle analysis, such as the one led by CIC energiGUNE in the HIGREEW project that it coordinates, is a recognized tool for assessing the environmental impact during the entire life cycle of stationary storage systems, i.e., their sustainability.