Rechargeable batteries are the key to transitioning away from fossil fuel dependence. Today’s Li-ion batteries use carbonate-based liquid electrolytes and intercalation-type graphite anodes.

However, these components have important drawbacks which hinder their future market penetration. On the one hand, carbonate-based liquid electrolytes are flammable and can leak (which makes them inherently unsafe); and on the other hand, graphite anodes provide insufficient capacity for high-energy-density applications.

Not surprisingly, then, the search for better battery materials has become a thriving research field.

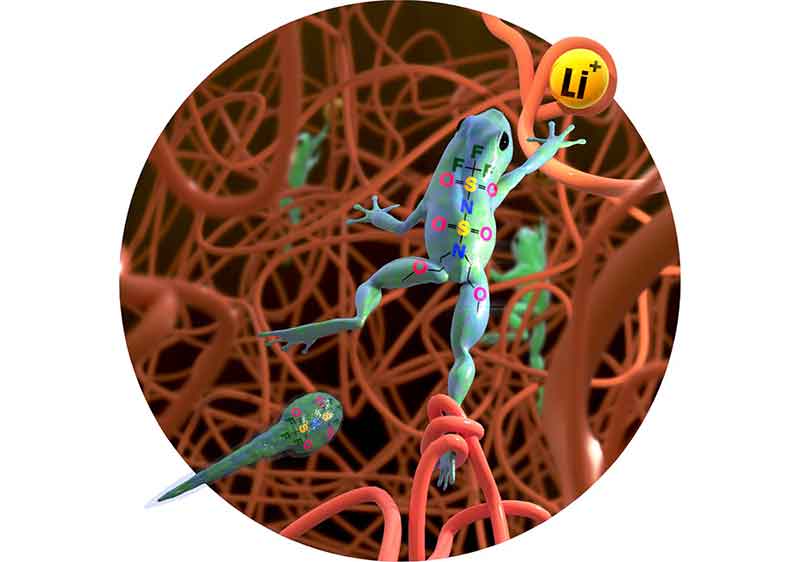

Solid polymer electrolytes, which comprise a lithium salt and an elastic polymer matrix, are considered promising alternatives to liquid electrolytes. Moreover, these solid-state Li-ion conductors have highly desirable characteristics for scalable fabrication.

First, they are easily conformable, which allow the successful manufacturing in geometries not accessible with conventional materials. Second, they have the ease of processing inherent to plastic materials. And finally, the fabrication is cost-effective, which boosts their commercial application.

In addition, solid polymer electrolytes are often less reactive towards Li metal compared to liquid electrolytes. This beneficial characteristic enables the use of high-energy-density Li metal anode as alternative to graphite. Li metal is an ideal anode because of its extremely high theoretical specific capacity, low density, and low electrochemical potential.

Solid polymer electrolytes hold therefore the potential to improve simultaneously the safety and energy density limitations of current Li-ion batteries.

Solid polymer electrolytes were first proposed by Michel Armand in 1978 within the concept of all solid-state lithium metal batteries. Since then, these materials have been deeply investigated. And the automotive industry has already brought their applicability to the spotlight.

In particular, Bolloré Bluecar® and Bluebus® electric vehicles have been introduced as public car-sharing services in cities such as Paris, Indianapolis, or Singapore. This represents a clear example of the viability of the technology.