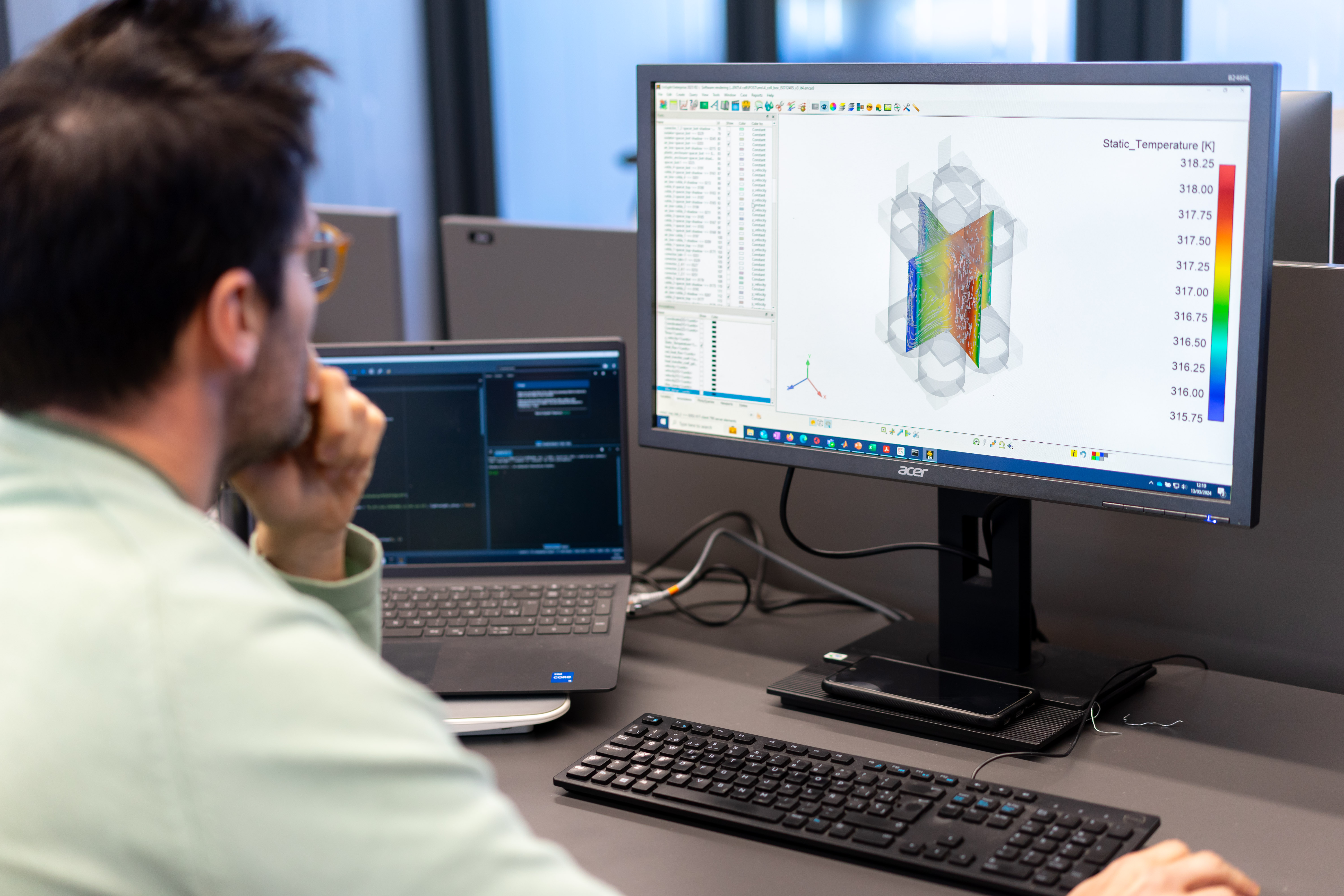

Thanks to advances in computing power, computational fluid dynamics (CFD) tools, and artificial intelligence (AI) techniques, modeling and optimizing an industrial thermal process is now faster, more accurate, and more cost-effective than ever.

At CIC energiGUNE, we apply these technologies with a different approach: that of applied engineering—combining the reliability of science with the agility that industry needs to achieve results in days, not weeks.

From Scientific Simulation to Industrial Results

Advanced simulation makes it possible to virtually reproduce the thermal behavior of a process, visualize energy losses, and evaluate alternatives without interrupting production.

What once required weeks of computation can now be solved in minutes, thanks to modern computing capacity and validated models.

This allows us to offer companies something concrete:

- Rapid diagnostics,

- Realistic solutions,

- And measurable economic returns.

In simple terms, modeling is no longer an academic task—it is now an immediate engineering tool for any type of industry.

Real Benefits: Less Energy, Fewer Emissions, More Competitiveness

The results are clear and measurable:

- Reduced energy and fuel consumption.

- Proportional decrease in CO₂ emissions.

- More stable, uniform, and safer processes.

The versatility of modeling tools allows easy multisector optimization. The following sectors have seen the greatest potential for savings:

- Cement and construction materials: CFD simulation of rotary kilns and precalciners allows combustion and gas recirculation optimization, achieving up to 8% fuel savings and 15% lower NOₓ emissions, while enabling the integration of alternative fuels.

- Forging, foundry, and automotive: Modeling metal flow and heat treatment in furnaces or molds improves temperature uniformity and reduces heating times, achieving around 20% energy savings and lower part rejection rates. In some plants, AI-based predictive models anticipate thermal deviations and automatically adjust heating curves in real time, increasing productivity without raising energy consumption.

- Chemical and pharmaceutical industries: Simulation of reactors, heat exchangers, or dryers combined with machine learning algorithms trained on plant data maximizes heat transfer and detects operational inefficiencies in real time. This hybrid CFD+AI approach has shown 10% improvements in thermal efficiency and up to 7% CO₂ reductions, optimizing operation without halting production.

- Ceramics and refractories: Flow and temperature analysis in tunnel kilns has reduced thermal consumption by about 12% and extended refractory lifespan, cutting downtime and maintenance costs.

- Food and beverage: Simulation of drying tunnels and pasteurization autoclaves has improved thermal uniformity and reduced steam or gas use by 10–15%, maintaining product quality. AI-based digital twins now dynamically adjust processing times according to moisture and load, minimizing consumption.

- Steel and metallurgy: In walking beam reheating furnaces, modeling has enabled burner and airflow redesigns, achieving up to 9% annual natural gas savings and better thermal uniformity. Advanced applications combine CFD with neural networks trained on operational data to create digital twins that predict part temperatures and adjust thermal power in real time, cutting energy use by an additional 5%.

- Paper and cardboard: In paper and corrugated plants, thermal simulation of drying sections and hot air recirculation has reduced steam consumption by up to 11%. Recent studies integrating AI with CFD have enabled predictive control systems that maintain target humidity with less energy, avoiding overheating and improving production stability.

- Power electronics and transformers: A thermo-fluid optimization study on a 50 MVA transformer reduced the hot-spot temperature by 2.8 °C, extending insulation life by 27% and reducing forced ventilation needs. Integrating AI with CFD has demonstrated the feasibility of real-time thermal monitoring models that detect cooling degradation or anomalies early, improving reliability and reducing corrective maintenance. These hybrid CFD+AI models are also being applied to medium-voltage cells, reducing hot spots and electrical losses by up to 5% and enhancing system reliability.

In all cases, the equation remains the same:

Lower consumption = lower cost = lower carbon footprint.

Beyond direct energy savings and competitiveness, current European frameworks offer additional economic incentives through official energy-efficiency mechanisms. Now is the time to take advantage.