Application areas of the thermal testing systems

Numerous industries benefit from this type of testing on the design and safety of high-temperature systems. Examples include the steel, foundry, automotive, chemical and ceramics industries, among others.

The following are some thermal test campaigns on industrial products that have provided relevant information for the design and optimization processes of these products:

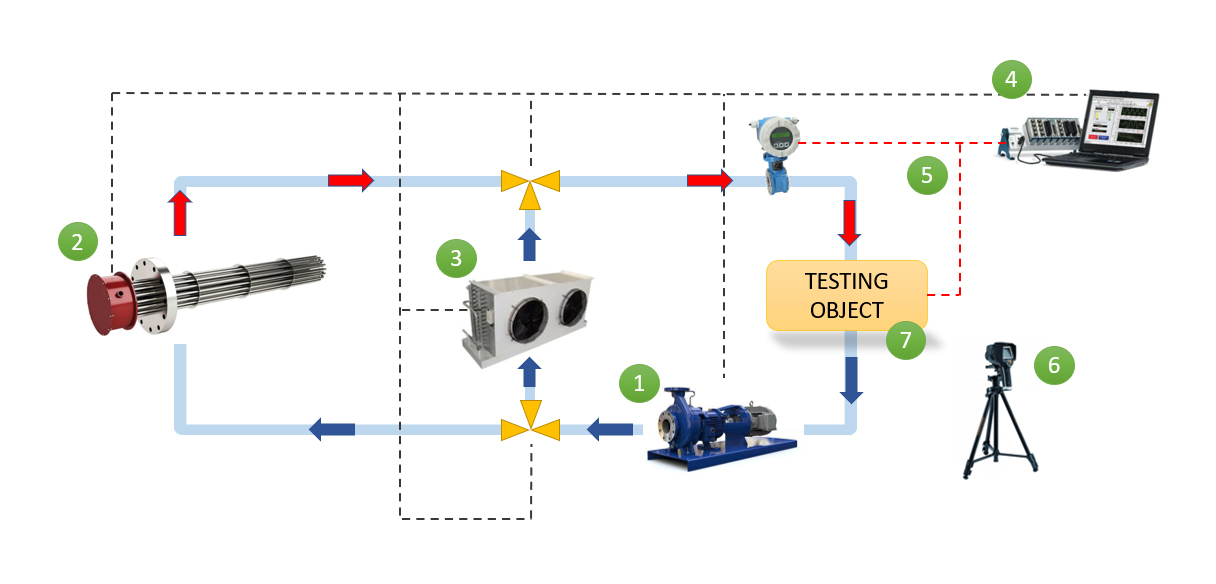

One of those case studies is the one carried out at the CIC energiGUNE facility with the oil loop. In this example, the facility was used to optimize and validate the design of a prototype of a thermal storage system for a solar thermal power plant using thermal oil with a temperature range between 180°C and 300°C. Accelerated life tests were carried out, determining not only the charging and discharging times of the storage, but also its behavior and mechanical deterioration. The results obtained made it possible to reduce the technological risk in the design of the commercial plant.

Regarding the air loop, as an example, the installation made it possible to compare the performance of two formulations of concrete for thermal heat storage, from 200°C to 600°C for industrial applications. To this end, two systems at a size close to real scale were exposed to thermal cycling, comparing their charging and discharging rates. The results made it possible to select the appropriate formulation within a very short time.

In another case, linked to the same air loop, it was used in conjunction with the thermography equipment to detect leaks in a plant supplying hot air at 700°C and showing flow rates way below the design points, which made it possible to optimize the plant´s operation.

Thanks to the steam loop, also, it was possible to validate a new steam accumulator design for cogeneration installations. For this purpose, the system was completely tested with steam at different pressure and flow levels, between 120°C and 300°C. As a result, both the operating ranges and the thermal capacities of the system were experimentally determined.

These examples demonstrate that the hydraulic loops offered by CIC energiGUNE are a way to obtain fast and reliable experimental results on products exposed to extreme thermal conditions. In this way, it is possible to drastically reduce product design times and achieve an early impact on turnover. In addition, the combination of these testing capabilities and the experience of our research team provides our partners with an additional way to introduce disruptive, efficient and low-cost advances in their designs.