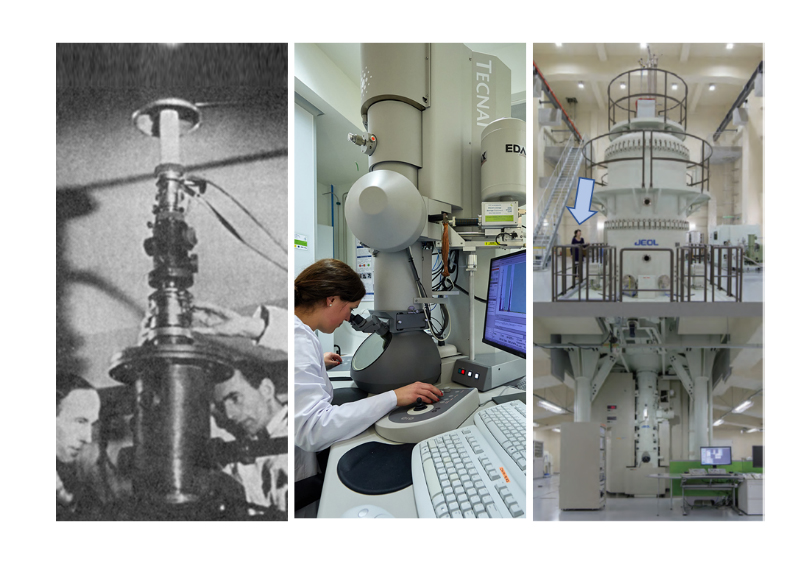

Since the first prototype of an electron microscope was invented in 1932 by Max Knoll and Ernst Ruska, electron microscopy has opened a window into the atomic world. In fact, equipment such as those available at CIC energiGUNE has allowed to study in the nanometric scale and to correlate different physical and chemical properties of a wide range of materials used in batteries.

Among the most powerful electron microscopes we can find the JEM 1.25 MeV UHV (ultra-high voltage). With more than one million electron volts as acceleration voltage and a size that can occupy two rooms, this equipment is able to obtain high spatial and temporal resolution on materials and biological samples of a few micrometers thick.

A picture is worth a thousand words

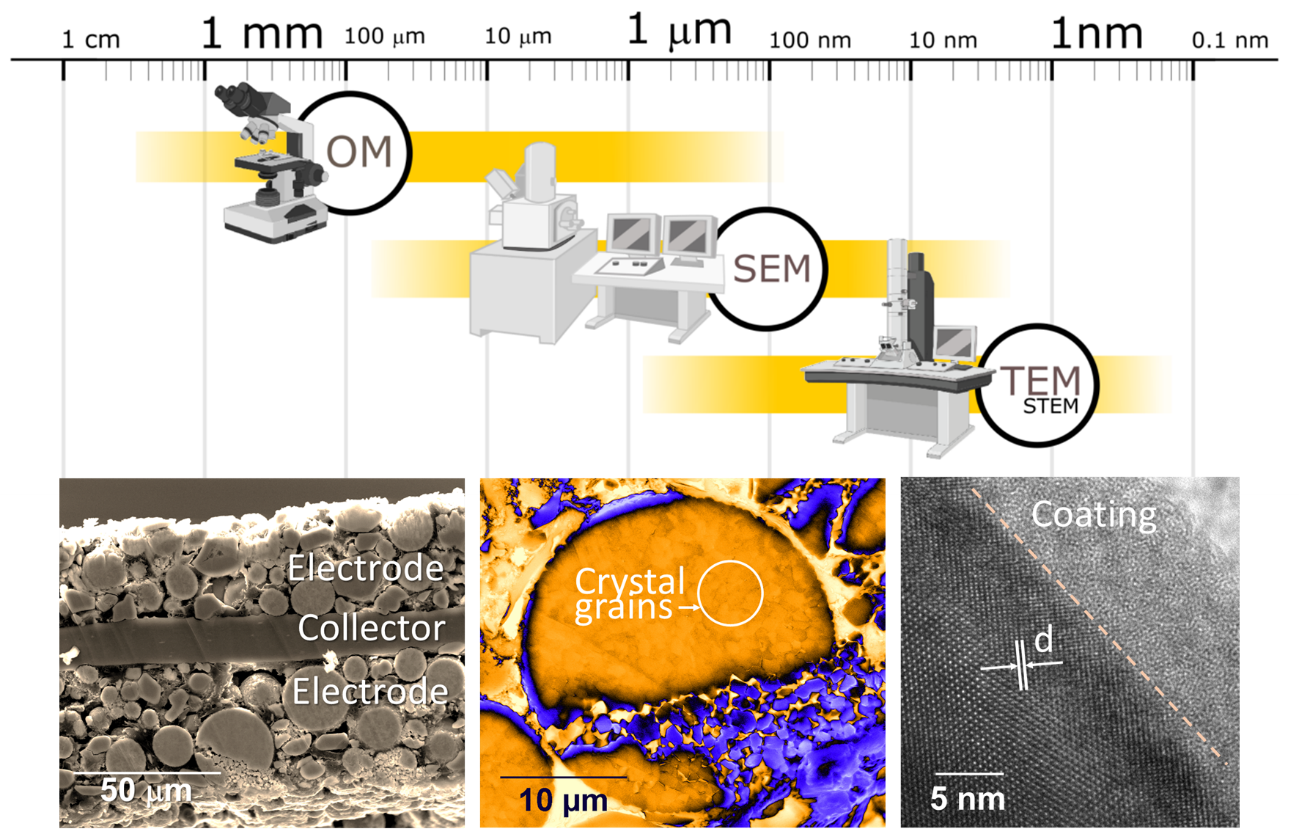

Unlike conventional optical microscopes, electron microscopes use electrons instead of light to create an image of the samples, giving them a higher magnification and spatial resolution.

The two fundamental electron microscopy techniques are the Scanning Electron Microscopy (SEM) and Transmission Electron Microscopy (TEM), and they can provide deep structural information at the nanometer scale of materials. Nowadays the capabilities of SEM are better than optical microscopes and even better the capabilities of TEM allowing to achieve resolutions up to atomic level (up to 0.17-0.2 nm by using the spherical aberration correctors).

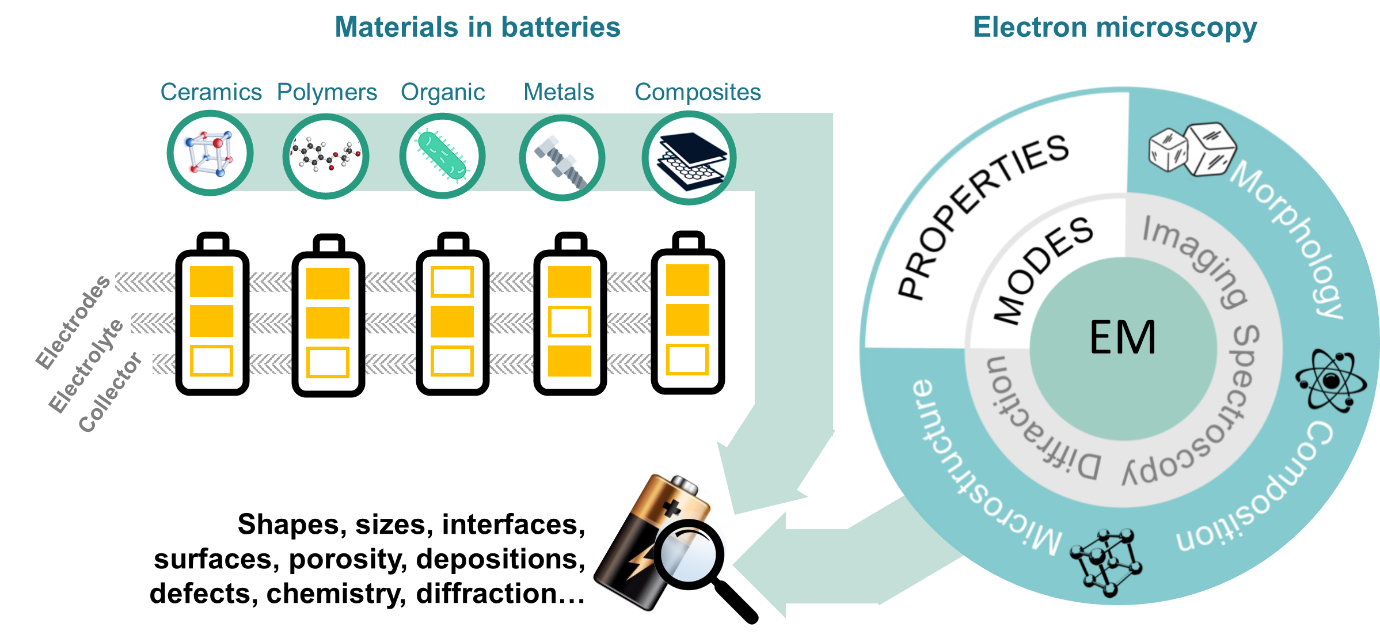

At CIC energiGUNE, electron microscopy makes part of the basic morphological analysis techniques for solid samples and it is carried out at different stages of the production and research of materials for batteries.

The diversity of commercial batteries arises from the number of materials that can be implemented or combined within each of the three fundamental parts of a battery: electrodes, electrolytes and collectors. This, together with the current trend to optimize the capacity and size of these devices, makes them complex systems that demands the use of advanced analysis techniques such as SEM and TEM microscopies.

For this reason, the electron microscopy platform at CIC energiGUNE has specialized in basic and advanced morphological, compositional and microstructural analysis of different types of materials, and it has focused on the study of a wide variety of topics such as: sizes, shapes, counting of particles, surfaces and interfaces, porosity, depositions, defects, composition, diffraction, among others.

Electron microscopy at CIC energiGUNE: to batteries… and beyond

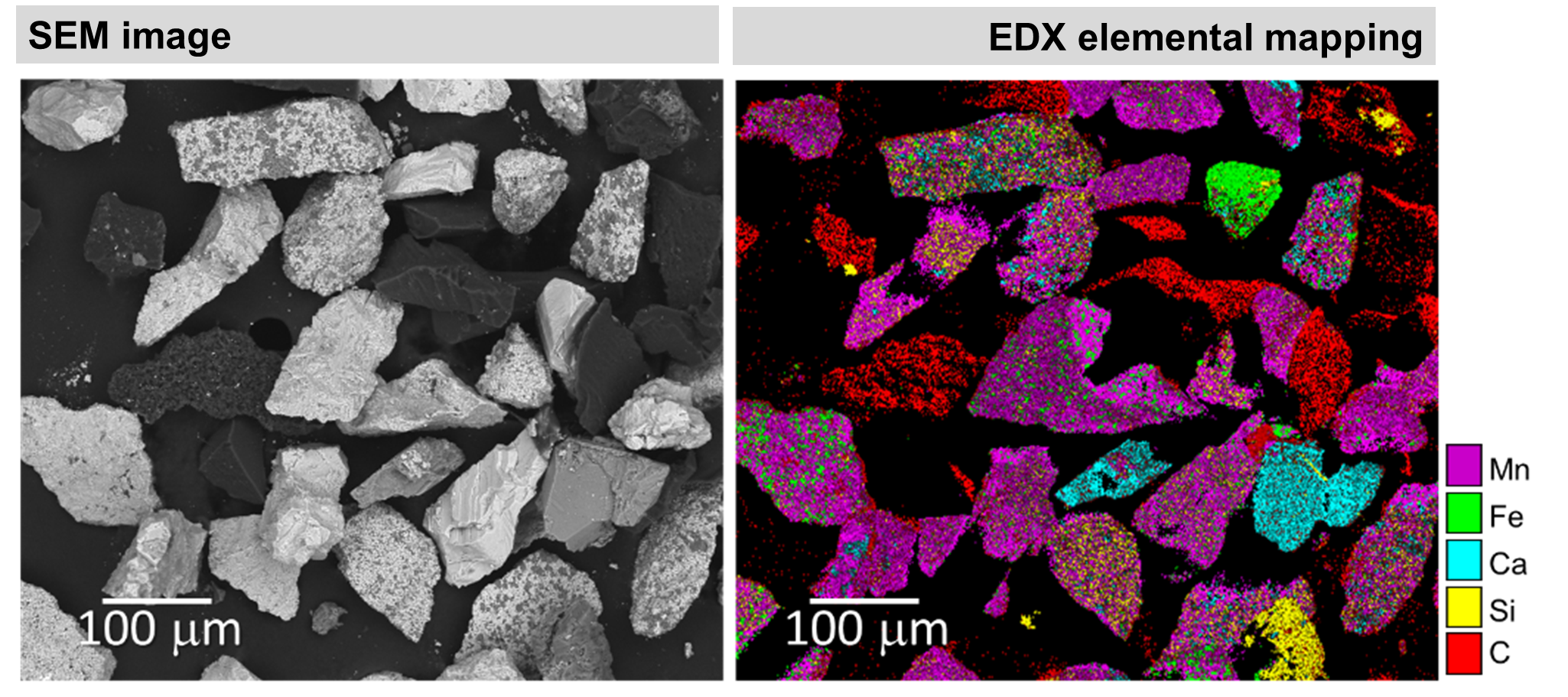

Electron microscopy, besides of being a very powerful magnification technique for the submicroscopic observation of materials, it is also a very versatile tool. Thanks to the interaction of the electrons in the incident beam with the atoms in the sample, it is possible to carry out chemical analysis of materials. Moreover, as a more advanced method, mappings allow to directly observe the distribution of elements in the selected area of a sample.

At CIC energiGUNE, compositional EDX analyses are continuously carried out on microscopes (TEM and SEM) during the different stages of development of battery materials. More specifically, morphological-compositional analyses are performed by comparing conventional SEM images with elemental analysis images obtained from the EDX technique.

Besides of giving the distribution of elements, EDX mappings allow to correlate the shape or size of the particles with their composition. In this way it is possible to study, locally or globally, the elemental composition on different parts of samples.

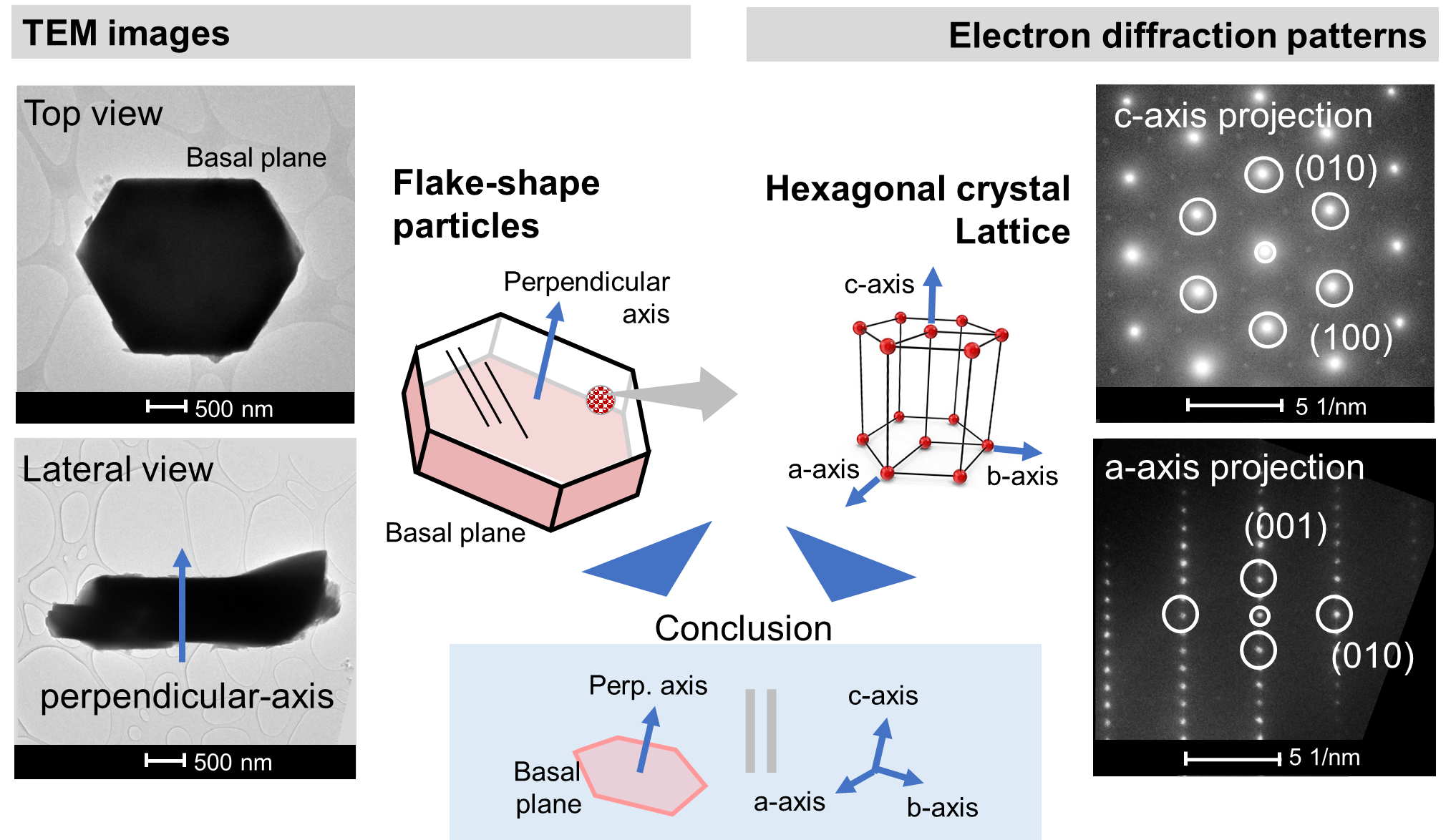

Another proof of the versatility of electron microscopy is its ability to give crystal information of materials using the electron diffraction technique. Due to the fact that electrons accelerated at high voltages interact with the arrays of atoms (crystal lattices) into the samples, they produce diffraction patterns directly related to the crystalline structure of the studied material. Thus, electron microscopy becomes a complementary technique to the X-ray diffraction technique.

For example, in the case of a crystalline electrode, TEM analysis exhibited the flattened-shape of the particles. On the other hand, electron diffraction studies have confirmed the presence of a hexagonal crystal lattice and have allowed to relate particle shape main directions with the crystal orientation. Thus the crystallinity, microstructural defects and crystal lattice/morphology correlation are studied by TEM and allow control the synthesis of new materials studied at CIC energiGUNE or to understand the failure rate of materials implemented in commercial batteries (in line with Postmortem analysis).

Therefore CIC energiGUNE, besides of counting with advance equipment, materials and experts for battery research, also provides custom solutions adapted to the needs of its collaborators, including expert advice on prototyping and characterization platforms (EMP, XRD, NMR...) for the resolution of problems associated with energy storage and other challenges related to the sector such as solutions for hydrogen or thermal energy.