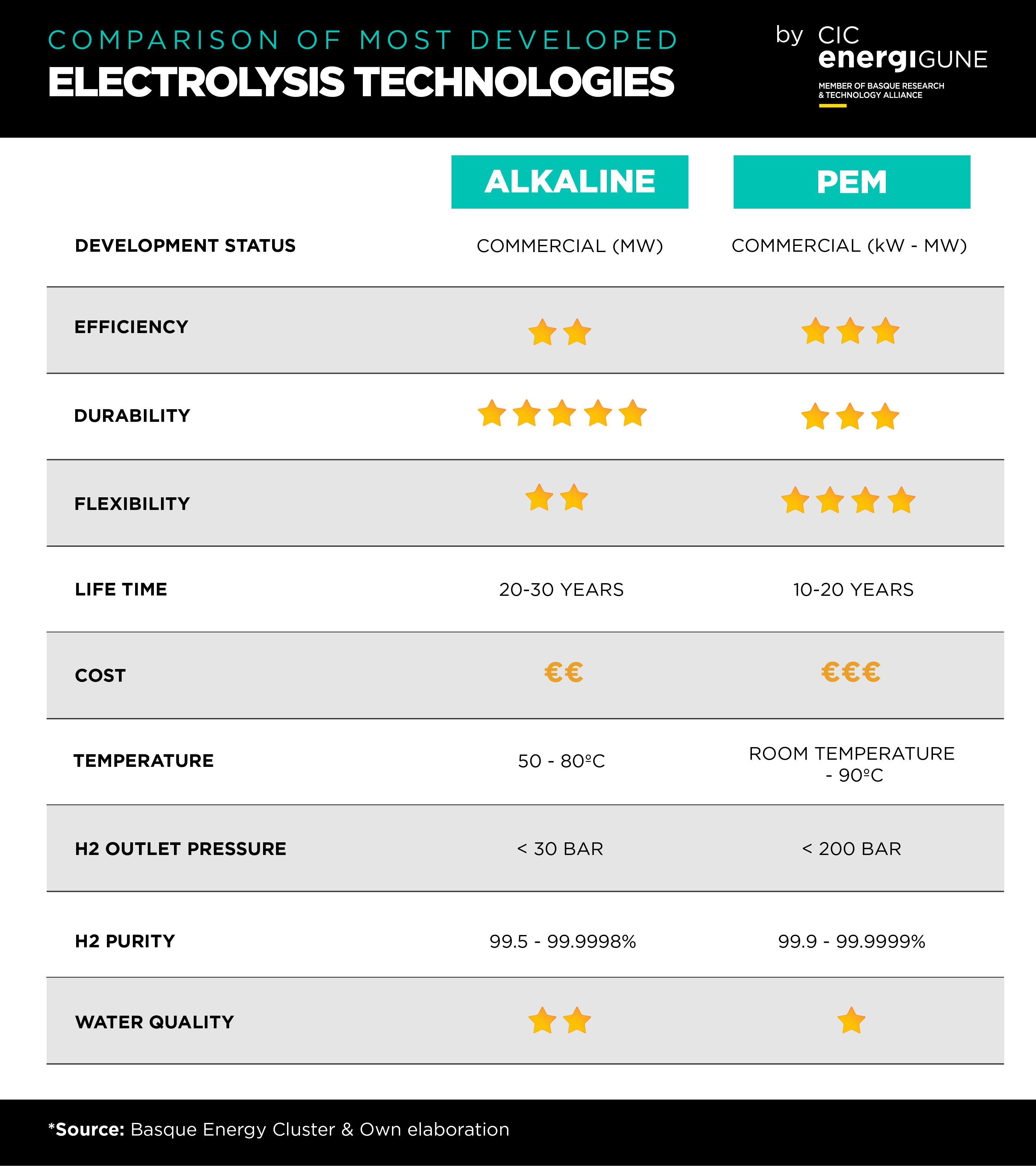

One of the best examples of this is the manufacturing industry associated with the production of electrolyzers, which are the key devices for achieving hydrogen production from what is known as electrolysis.

This chemical process separates the hydrogen and oxygen molecules that make up water through renewable electricity (or, at least, without carbon emissions). Thanks to this, the so-called "green hydrogen" is obtained, the only type of H2 that does not emit CO2 into the atmosphere during the production process.

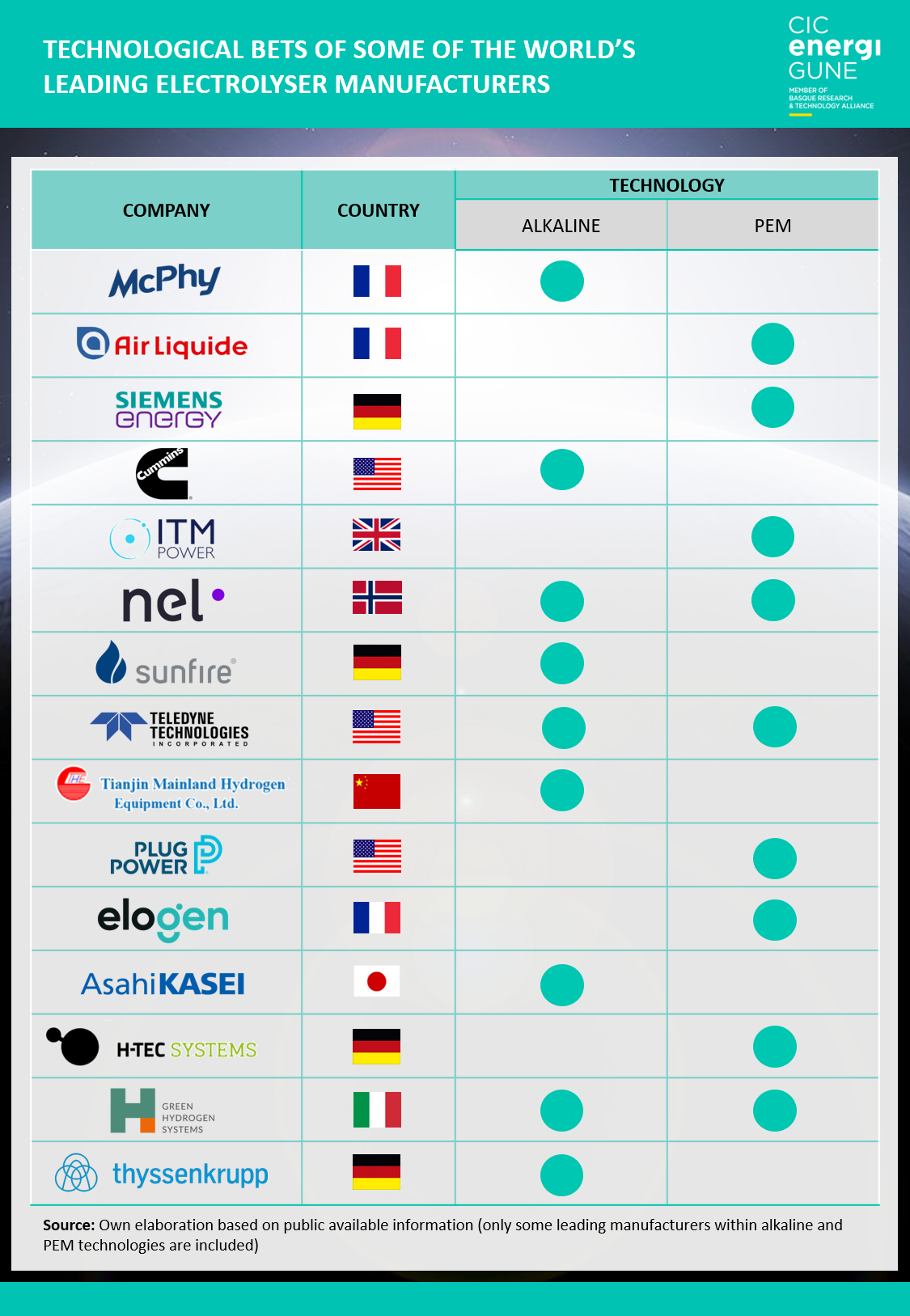

Due to such characteristics and the importance of developing a "green" hydrogen industry, the manufacture of electrolyzers is gaining more and more prominence. Not only because the subsequent deployment of H2-based applications will depend on its technological advances, but also because the different countries and regions of the world are seeking to dominate this stage of the hydrogen value chain to ensure their future supply and independence in energy terms.

For example, Europe, as well as other examples such as batteries, is working hard to develop its own industrial network around hydrogen.

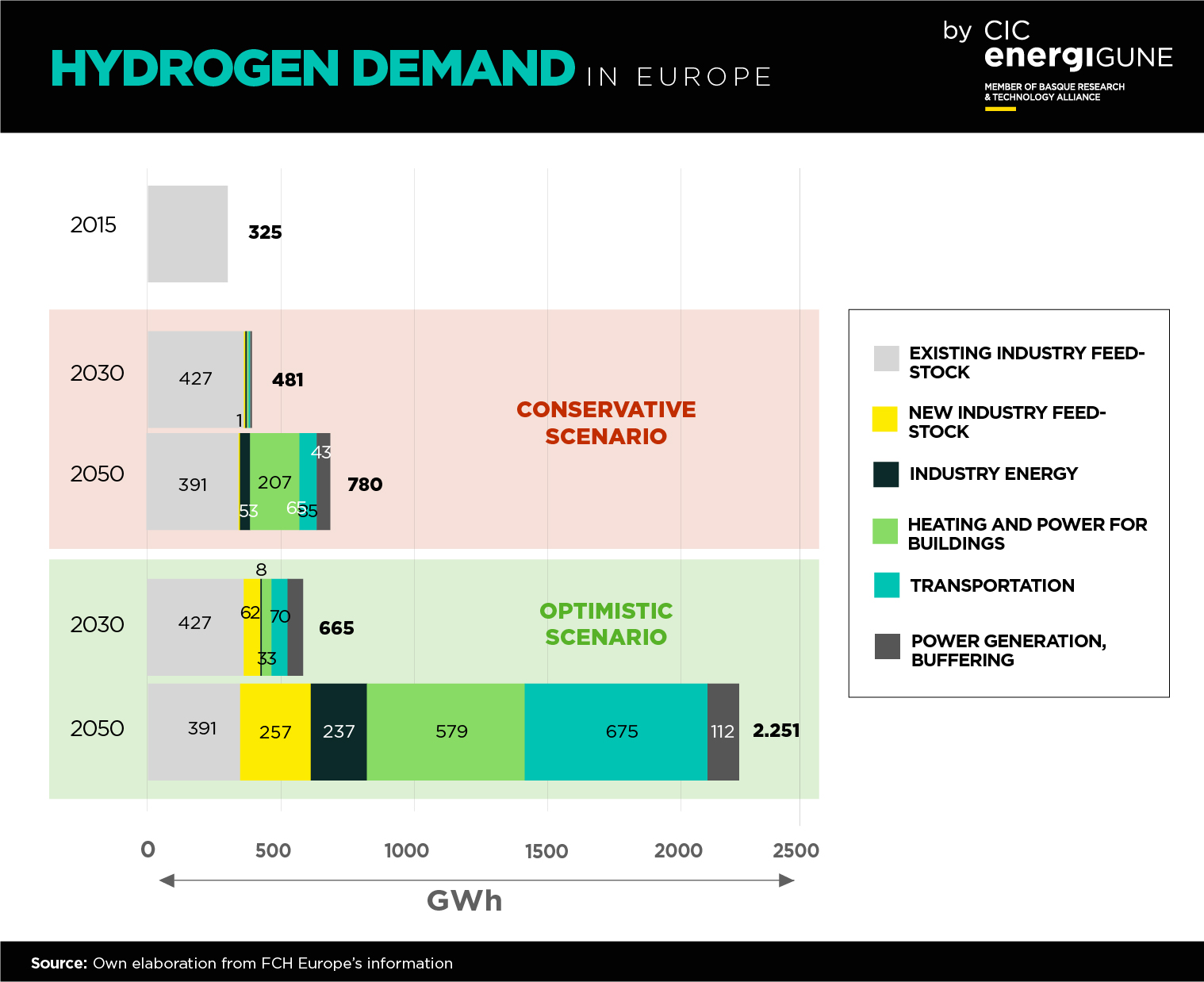

Not surprisingly, according to estimates by the Clean Hydrogen Partnership (the main EU public-private initiative related to the H2industry), it is expected that by 2050 the demand for hydrogen on the continent could exceed 2,250 TWh in an "ambitious" scenario, in which the continent has been able to boost the different stages of the hydrogen value chain in its territory, including the capacity to produce it.