The European Union united for electric vehicles

The European Union aims to be a benchmark in the electric vehicle battery sector, aiming to be responsible for 30% of battery production by 2030 and to have at least 30 million electric vehicles on its roads by the same year.

The SAFELiMOVE project starts from this aspiration with the aim of creating a competitive European solid-state battery technology. The main competitive advantages of the SAFELiMOVE technology are:

- The increase of driving range by an additional 300 kilometers on a single charge.

- Reduced charging time.

- Increased safety due to the absence of the potentially flammable liquid electrolyte.

- The decrease in battery cost by 50%, thanks to the use of highly efficient materials and processes.

The outstanding performance of electric vehicles powered by SAFELiMOVE´s solid-state technology will increase the demand for electric vehicles, which will strengthen the European electric transport supply chain and protect our planet by decreasing greenhouse gas emissions from road transport.

This development is only possible thanks to the combined expertise and capabilities of the SAFELiMOVE consortium participants, which include many of Europe´s leading players in electric vehicle battery development.

The European consortium covers the entire battery value chain from companies specialized in materials development such as Schott (Germany) with their innovative inorganic materials, Umicore (Belgium) with the advanced cathodes, Hydro-Québec (Canada) with their state-of-the-art lithium metal; the battery modeling experts Avesta battery & Energy Engineering (Belgium); the battery manufacturer SAFT SAS (France); the OEMs Renault (France) and Toyota (Belgium); and finally the company in charge of life cycle analysis and cost cycle Life Cycle Engineering technology (Italy). These companies are supported by 5 leading European research centers in the field and led by CIC energiGUNE.

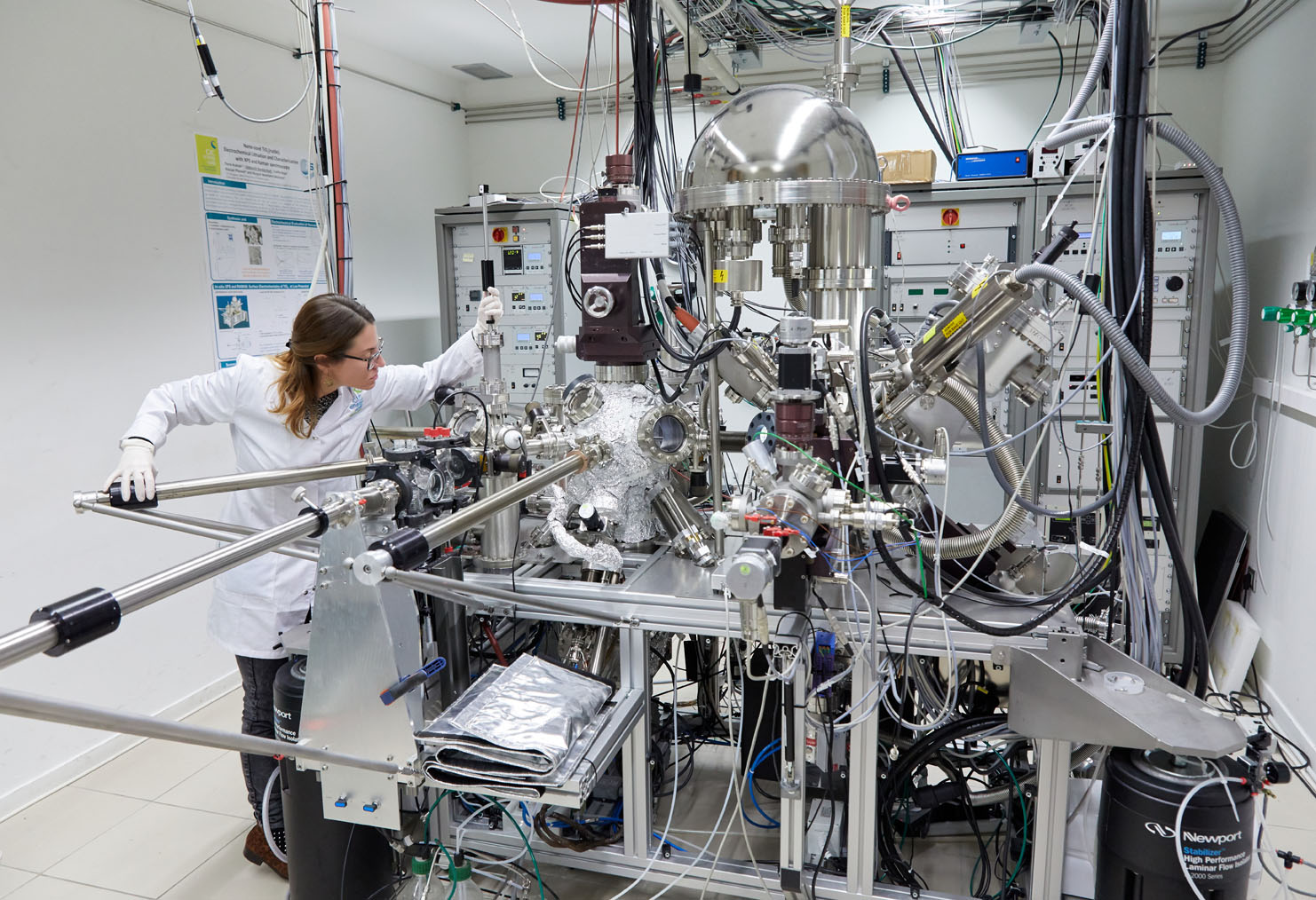

CIC energiGUNE´s role in SAFELiMOVE

CIC energiGUNE leads the project, which involves the technical-scientific and administrative coordination of the 15 partners that make up the consortium. In addition, the solid-state battery research line at CIC energiGUNE led by Michel Armand, a renowned pioneer researcher in the field, is responsible for developing the hybrid solid-state electrolyte of the project, first developing the polymer electrolyte and then carrying out the hybridization with the inorganic materials developed by Schott AG. Finally, CIC energiGUNE is coordinating the interface analysis work, a key aspect for understanding how the cells work.

During the first 18 months of the project, CIC energiGUNE has been a key player in achieving the first milestone of the project: the development of the first generation of SAFELiMOVE materials. Schott AG, Umicore, Hydro-Québec, Avesta battery & Energy Engineering and CIC energiGUNE have worked closely for this achievement. The partners developed an initial set of materials consisting of a new polymer developed by CIC energiGUNE, oxide electrolytes, NMC cathode material and an ultra-thin lithium metal foil. The materials were characterized and their compatibility has been demonstrated.

In the same time, CIC energiGUNE contributed to the achievement of the second milestone of the project: the manufacturing of the first batch of SAFELiMOVE technology coin cells and mono-cells. Specifically, CIC energiGUNE was involved in the definition of the processing for the electrolyte and cathode including issues such as the type of solvents to be used, the calculation of the polymer/solvent ratio, the optimal mixing, casting and drying conditions.