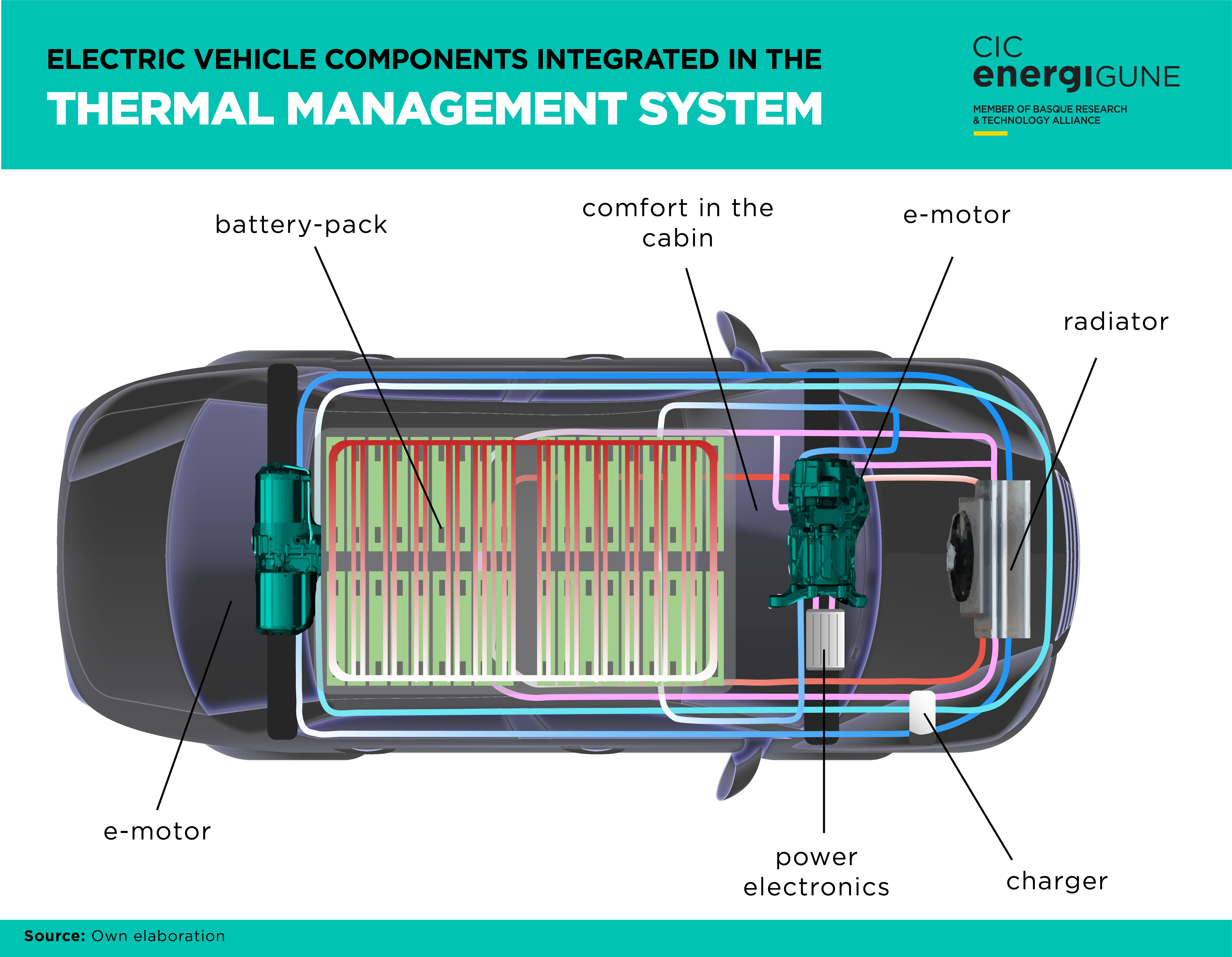

This article aims to identify the thermal needs and features of each of these components, analyzing the current and future trends in the sector in terms of integrated thermal management in electric vehicles.

Electric motor (e-motor)

Along with the battery pack, the e-motor is one of the critical components in the electric vehicle. When it comes to thermal management of the e-motor, there is no need to warm-it-up, so all the solutions proposed at a commercial level are aimed at cooling its components. In fact, the cooling of the e-motor is of great importance because the efficiency of electro-mechanical conversion decreases significantly when the temperature rises.

With this in mind, within the electric vehicle, the e-motor has to be considered as a heat generating component; heat that can be captured and reused in other systems that demand it within the vehicle, with the ultimate goal of improving energy efficiency and extending the vehicle´s range.

Analyzing the solutions proposed by companies in the sector such as Volkswagen AG, YASA or Punch Powertrain NV, there are mainly two cooling alternatives for the e-motor. On the one hand, there is the use of an external cooling jacket and, on the other hand, internally through the rotor shaft. In both concepts, the proposal is to use liquids as heat transfer fluid (water, coolants or thermal oils). The selection of the cooling technology of the e-motor depends directly on its power, being necessary a combination of both in the case of high power motors. Regarding the selection of the fluid, this will depend on the fluid used in the rest of the vehicle components. In extreme cases, such as competition vehicles, the need to immerse the engine in oil is even considered as the only method to achieve the necessary cooling power.

Thermal comfort inside the cabin

A debate that arises in the electric vehicle with the elimination of the internal combustion engine (ICE) is, how to fulfill the thermal demand of the cabin to achieve passengers´ comfort. In ICE vehicles, this heat is "free" as it comes from engine inefficiencies and is generated at high rates, with the excess having to be evacuated to the outside. However, heat generation due to inefficiencies in the different components of the EV is much lower, and in many situations it is not enough to meet the total demand. In this sense, it is necessary to have an auxiliary system that, using the energy stored in the battery, generates the necessary heat.

In this context, the focus is on the most efficient way to satisfy the comfort of the vehicle passengers. Among the options considered are the use of air to heat the cabin as has traditionally been done, heating only surfaces such as the seats, the steering wheel, etc., or a combination of both.

Regarding the use of air, the simplest and most economical way is to use electric resistances. However, this alternative presents low efficiencies compared to the use of heat pumps (more expensive). The use of direct surface heating is seen as an alternative to optimize energy use and ensure thermal comfort by heating only those areas of the cabin where there are occupants.

It appears to be no consensus on a standard solution. Nowadays, the industry´s current thinking seems to be different for small vehicles and premium vehicles. The first ones, in which cost reduction is a priority, usually include an air-conditioning system based on air heated by resistances as standard and, optionally, offer a heat pump, with the aim of minimizing electricity consumption and, therefore, increasing the vehicle´s range. In premium vehicles, however, the standard solution tends to be a combination of heat pump (air) and surface heating (seats and steering wheel).