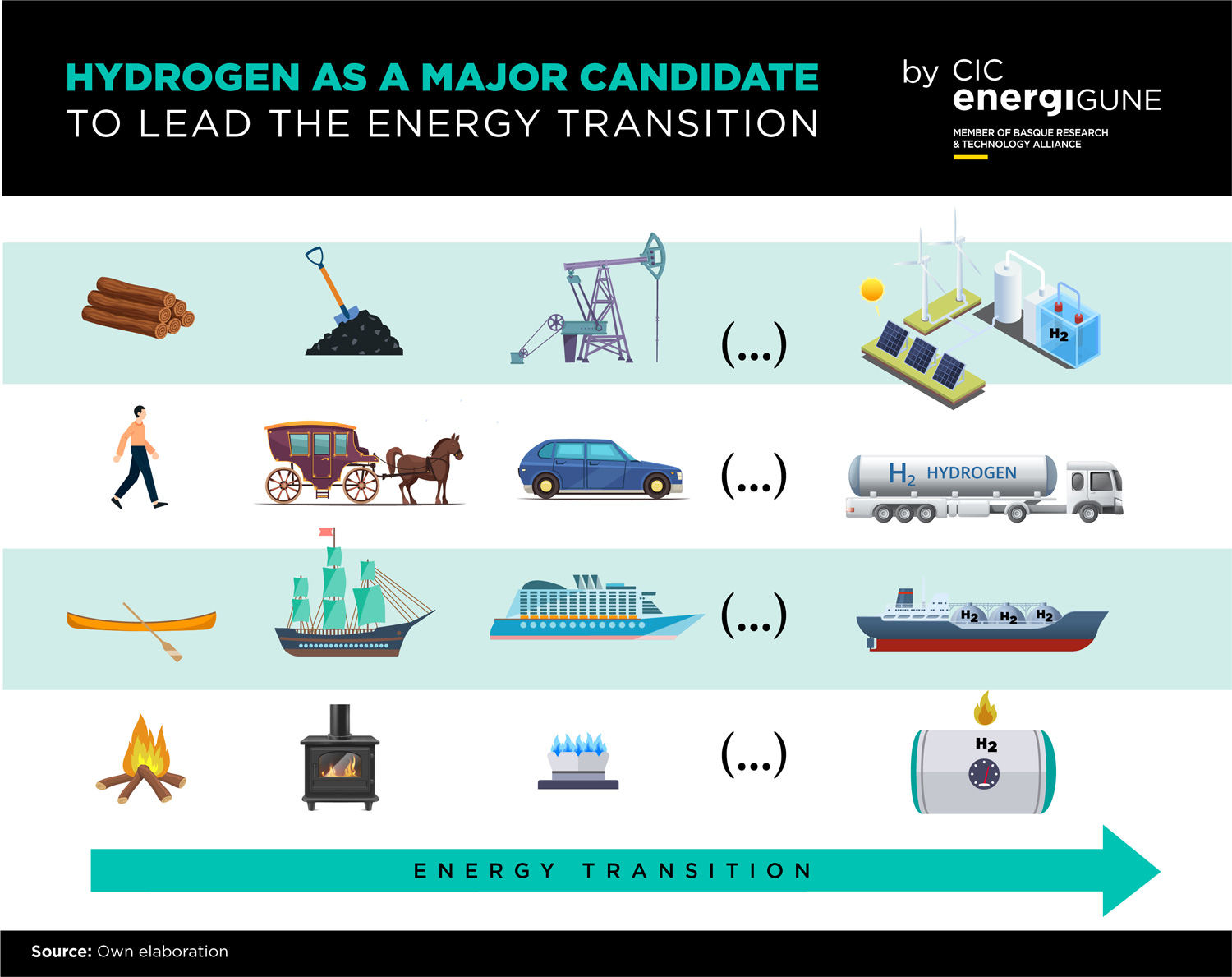

Let’s go back in time to learn from the past.

During the 19th and 20th centuries, horses were the broadly used means of transport, both in urban and rural areas. They moved the economy and controlled the supply chain. Horses were an extremely cheap and highly effective user of “energy”, achieving efficiencies more than triple that of coal-fired engines. Horses were even a source of job generation.

However, this engine of public life soon became a source of waste, with horse manure becoming a massive negative impact on society and the environment. The growing population and the need for more horses caused huge health and environmental problems and were logistically complex to manage. Let’s consider, for example, diseases associated to dried manure dust and soaked manure mire, not to mention the smell, the flies and the deaths related to horse traffic.

Thus, the transition from horse transportation to automobile was a reasonable and seemingly positive environmental choice.

Moving forward in time to 1952, the smog produced by industry, residential heating and transport caused serious air pollution that killed as many as 12,000 people in London. Such an event was the driving force for the 1956 Clean Air Act, which restricted the burning of domestic fuels in urban areas.

This was a cornerstone for the progressive transition away from coal at the railways, in gas manufacturing, in many homes and in most industries.

250 years after the coal-driven industrial revolution and 140 years after the first patent for a vehicle powered by a gas engine, we are now facing similar public health and environmental challenges.

Different alternative energy sources have been proposed to lead the energy transition having all advantages but also challenges associated to cost, implementation or widespread distribution. One of the alternatives called to lead the new energy transition, it is the use of green hydrogen, obtained from electrolysis, as energy vector. But, could hydrogen lead this new transition to a cleaner economy?

Hydrogen offers a large number of advantages over other energy vectors to lead the energy transition:

For all these reasons and more, wherever we go today “Hydrogen Economy” (as the concept that entails all the supply chain -production, storage, distribution and utilization-) is the chosen buzzword.

But the question that follows is: When is going to happen?

For many years, during the late 90’s and early 2000’s, the transport sector was believed to be the engine for a transition to Hydrogen Economy; however, the upsurge of the plug-in and fully electric vehicles has mostly changed the electrification paradigm of mobility in the past five years. So, what’s next? If battery cars are the present, why the surge of the Hydrogen Economy vocabulary in the last years?

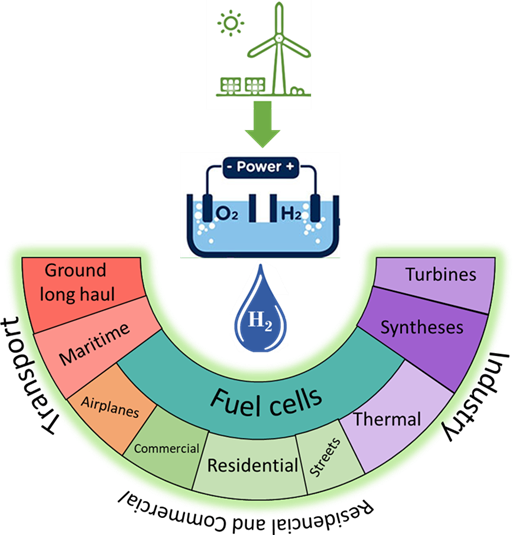

We believe the transition to Hydrogen Economy will be driven by something other than personal vehicles. While batteries are the most immediate answer for electrification of light-duty transportation, hydrogen focuses on providing solutions to a key sector like the heavy-duty and long-haul transport. In fact, trucks, trains, boats and planes constitute 68 % of the CO2 emissions of the transport sector.

In addition to the transport sector, hydrogen has the potential to lead the energy transition to a clean, secure and affordable energy future in industry and in urban areas, but must then be adopted in energy-intensive industries (e.g. steel and cement), urban heating and illumination. In some of these cases, hydrogen will be use in a fuel cell to generate electricity; in other cases, hydrogen will be use as a fuel in a combustion oven to generate heat free of CO2 emissions.

Regarding the scenario where hydrogen is used as a fuel in a fuel cell to generate electricity, for a few decades, scientists and industry have been developing fuel cells that will enable the use of hydrogen and hydrogen-containing fuels in not only transport, but also off-grid stationary applications (e.g. electricity generation for buildings).

Even though fuel cells are not fully deployed in the market like batteries, fuel cells are commercially available, as evidenced by the following cases. The major car manufacturers have hydrogen fuel cell electric vehicles available in the market including the Toyota Mirai, Hyundai Nexo, Mercedes-Benz GLC F-CELL, Honda Clarity and BMW fuel cell iX5.

The same happens with Hynova Yachts, based in France, which is adopting hydrogen fuel cells from Toyota to power 40-foot boats. Regarding stationary applications, fuel cell power for off-grid applications -from communication towers to electricity back-up for buildings- is also a reality. And in 2020, even Microsoft reported the use of hydrogen back-up generators supporting one of their data center’s servers.

On the other hand, Fuel Cell Systems, Ltd demonstrated the flexibility of hydrogen fuel cells to deliver power to essential communications equipment in the Antarctic. And PowerUP produces hydrogen fuel cells to power different applications in the maritime industry and in telecommunication infrastructure.

So now, the question becomes: Why are not broadly implemented?

Even though hydrogen is the most abundant element on earth, it does not exist in its readily available gas molecular form. That means that hydrogen gas needs to be produced. Hence, the so-called colors of hydrogen, which refer to the way hydrogen is produced. Thus, at the present, hydrogen is mainly produced from hydrocarbons (grey, blue or turquoise). However, producing hydrogen from hydrocarbon still results in the emission of CO2. In contrast, green hydrogen – CO2 emission free – is produced by electrolysis of water (H2O) using renewable resources. But, as of today, of the total global annual hydrogen supply, 59% is produced from fossil fuel-based steam methane reformation of natural gas, 19% is produced from coal-to-hydrogen gasification, and only 1% currently is sourced from electrolysis. That is why the production of green hydrogen has become a key area of focus at to top of the emerging technologies watch list.

Nevertheless, the core problem of the wider implementation of green hydrogen is the cost: green hydrogen cost 10-12 €/kg vs 5-6 €/Kg for hydrogen grey hydrogen. Regarding the average cost of a hydrogen electrolyzer, it is mainly driven by the power supply (28%), various power components (45%) and water processing and circulation (12 %). Therefore, reduction of the cost of the green hydrogen production can be addressed by reducing the cost of the renewable electricity and of the components of the electrolyzers.

Several analysts predict that the cost of producing green hydrogen from renewables should fall 30% by 2030, enabling the scaling up of green hydrogen production. In contrast, the cost of the components of the electrolyzers is more complicated: 5-10% of the cost of the electrolyzer currently depend on the volatility of the prices of the catalyst (Pt, Ir, Ni, Co, Ru) and is therefore dependent of the availability of this metals, on fluctuations in the supply/demand and on geopolitical factors. Therefore, reducing the dependence on these critical materials will enable widespread use of technology, and precisely, at CIC energiGUNE, we are working to overcome these barriers by developing electrolyzer’s catalysts based on more Earth abundant materials.

Hydrogen is also facing limitations in terms of storage and distribution. The development of hydrogen infrastructure is not keeping pace with the need. So, this shortfall is holding back the widespread implementation of hydrogen.

Since the price of hydrogen for consumers strongly depends on supply/demand, the lack of a network of hydrogen distribution for homes and industry and the scarcity of hydrogen refuelling stations result in uncertainty and high costs to the consumer. And planning and coordination between governments, industry and stakeholders is likely to help to solve this problem.

So, what do we need to do next? Research and development at research centers such as CIC energiGUNE, is essential to lower costs and improve the performance/durability of electrolyzers and fuel cells. However, this is not the main limitation. Government actions and public funds are critical in setting the research agenda, taking risks and attracting private capital for innovation.

In addition to improvements in hydrogen technology and reduction of its cost, it is also important that industrial hubs boost the production and utilization of green hydrogen. Industry and governments across the World, should adapt existing and built new infrastructure for the transport and storage of hydrogen. In fact, an increase in demand of hydrogen will reduce its costs. Likewise, Governments should also eliminate unnecessary regulatory barriers and should favor policies that create sustainable markets for green hydrogen, underpinning investments in production, suppliers and users, as these investments will also significantly drive down the cost.

Fossil fuels helped modern society to create an industrial power and transform transportation. Now, the time is right to plug into green hydrogen’s ability to play a key role in a clean, secure and affordable energy economy. The technology is mature enough and the global circumstances claim we take actions.

Author: Paramaconi Rodríguez, Head of the Electrochemical Hydrogen Technologies research group, Electrochemical Storage area of CIC energiGUNE.

If you want to know the latest trends in energy storage and new developments in research, subscribe.

If you want to join a top-level team, collaborate with specialists in multiple disciplines or tell us about your concerns, don't think twice...