Above all, considering their characteristics and properties, they justify the suitability of proposing technological development paths that make both solutions go hand in hand and complement each other.

This approach is endorsed by the strategies that entities such as the EU itself have been launching in recent years, where the joint and coordinated deployment of both technologies can be seen.

Thus, the first strategy deployed by the EU in this regard dates back to 2017, when the initiative known as Batteries Europe was launched. Through it, the EU seeks to move from 3% of the European market share of batteries in 2018 to 25% in 2028.

In addition, the EU has also launched its own green hydrogen strategy, which aims to produce hundreds of tons of renewable hydrogen per year by 2050, with a strong presence in sectors such as transport, building and industry.

This plan has been defined with a clear vocation to "complement" the battery strategy already defined by focusing on the decarbonization of sectors of the economy that could not achieve the desired energy transition only through electrification based on batteries and renewable energy sources.

This is demonstrated, for example, in the first "Green Deal" call published in May 2020 at the EU level, where it already speaks in its area 5 ("Sustainable and Smart Mobility") of hydrogen and battery hybridization in demonstrators for future maritime and air means of transport.

Similarly, the International Energy Agency (IEA), in its document "Batteries and hydrogen technology: keys for a clean energy future", reveals that it will take more than renewable energy and efficiency to put the world on track to meet climate and other sustainability goals. It identifies both batteries and hydrogen as keys to a low-carbon society.

BATTERIES AS A KEY FACTOR IN BOOSTING GREEN HYDROGEN

As indicated above, this joint approach between the two technologies is largely based on the similarities and complementarities between the two technologies.

Not surprisingly, batteries and electrolyzers (how coveted green H2 is obtained) are based on similar electrochemical principles, making it possible to take advantage of the knowledge generated in one technology for the benefit of the other as the use of similar components and elements.

It is therefore expected, for example, that given the increasing maturity of the battery industry, the future large-scale industrialization of electrolyzers will take advantage of this knowledge and experience, reducing the time to scale and the associated costs. This also explains why more and more players are working on both technologies, taking advantage of existing synergies to offer innovations that benefit both.

But beyond these common principles from which both batteries and H2 can benefit, other elements justify the need to propose a technological roadmap that considers these solutions’ complementarity.

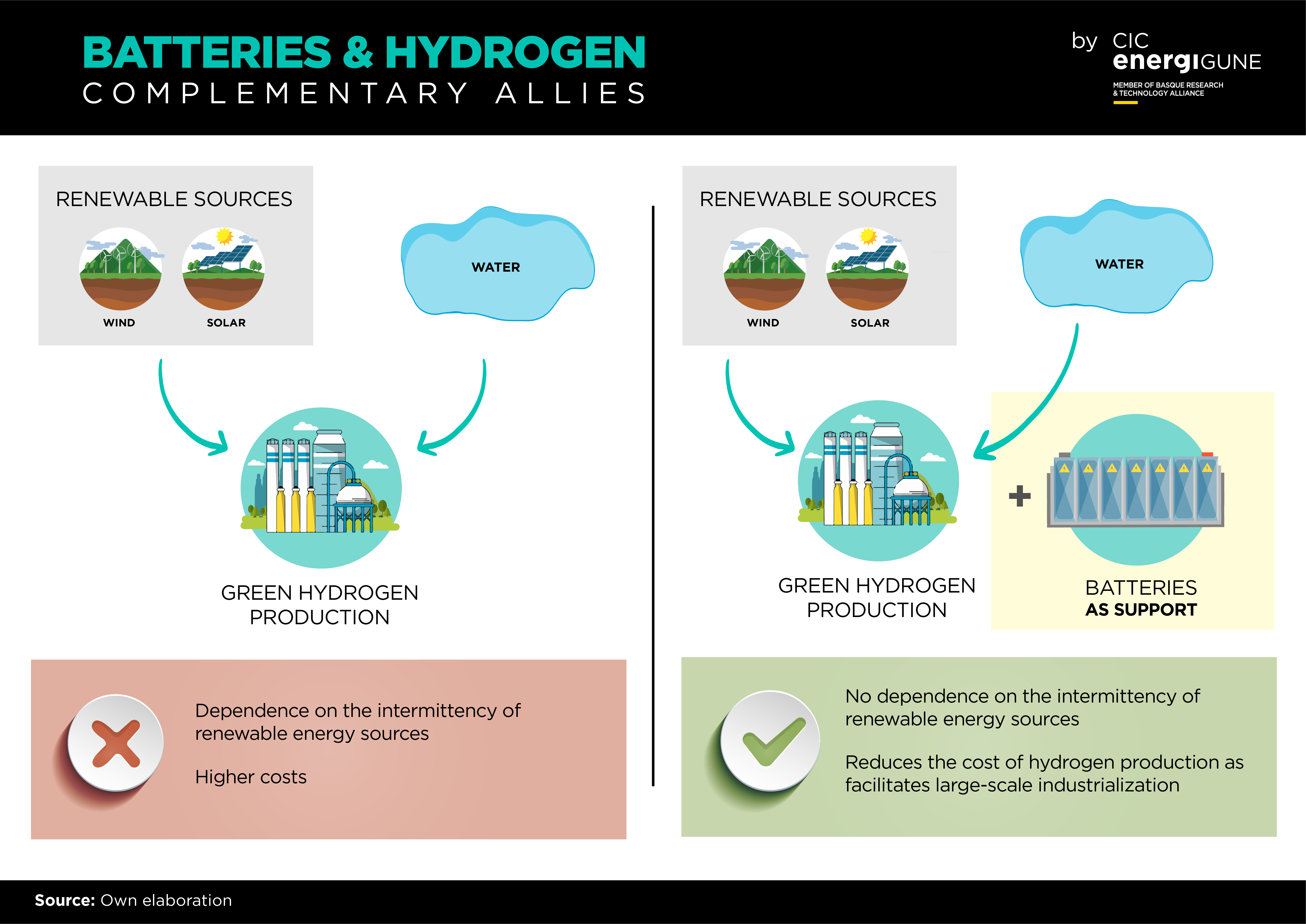

As detailed in previous posts in our blog, the efforts of the H2 industry are currently focused on boosting the production of H2 through the electrolysis of water based on renewable energies (such as wind or solar energy). This will make it possible to generate a sustainable, emission-free production process, which will further strengthen the commitment to this technology with a view to the energy transition.

However, as it is based on "intermittent" energy sources such as those mentioned above, green H2 poses the challenge of establishing a stable production system that guarantees its production without having to depend on weather conditions at any given time. This is where the potential of batteries to increase hydrogen production through electrolyzers arises.

Thanks to their storage capacity, batteries make it possible to eliminate the uncertainty and dependence associated with the availability of renewable energies depending on the time of day or the weather forecast. Thus, potential energy surpluses can be stored for later times when a deficit occurs. This avoids losses or waste of energy, thus achieving greater efficiency in its use.

Until a few years ago, this approach was not considered within the electrolyzer sector due to the high price of batteries, which meant a significant increase in the final cost of electricity obtained from hydrogen. This is why it was considered a more profitable option to reduce the degree of utilization of electrolyzers to only those times when renewable energy was available.

However, this scenario is not the same today, where the reduction in the price of batteries has reached such a level that their commissioning in electrolyzer plants is beginning to be profitable, also making it possible to increase the degree of utilization or plant factor of the installation thanks to the storage of energy in surplus phases for later use in times of deficit of renewable sources.

Electrolyzer plants such as the one being developed by Iberdrola in Puertollano (Spain) already contemplate this approach, which aims to boost the attractiveness and growth of the green H2 production industry worldwide.