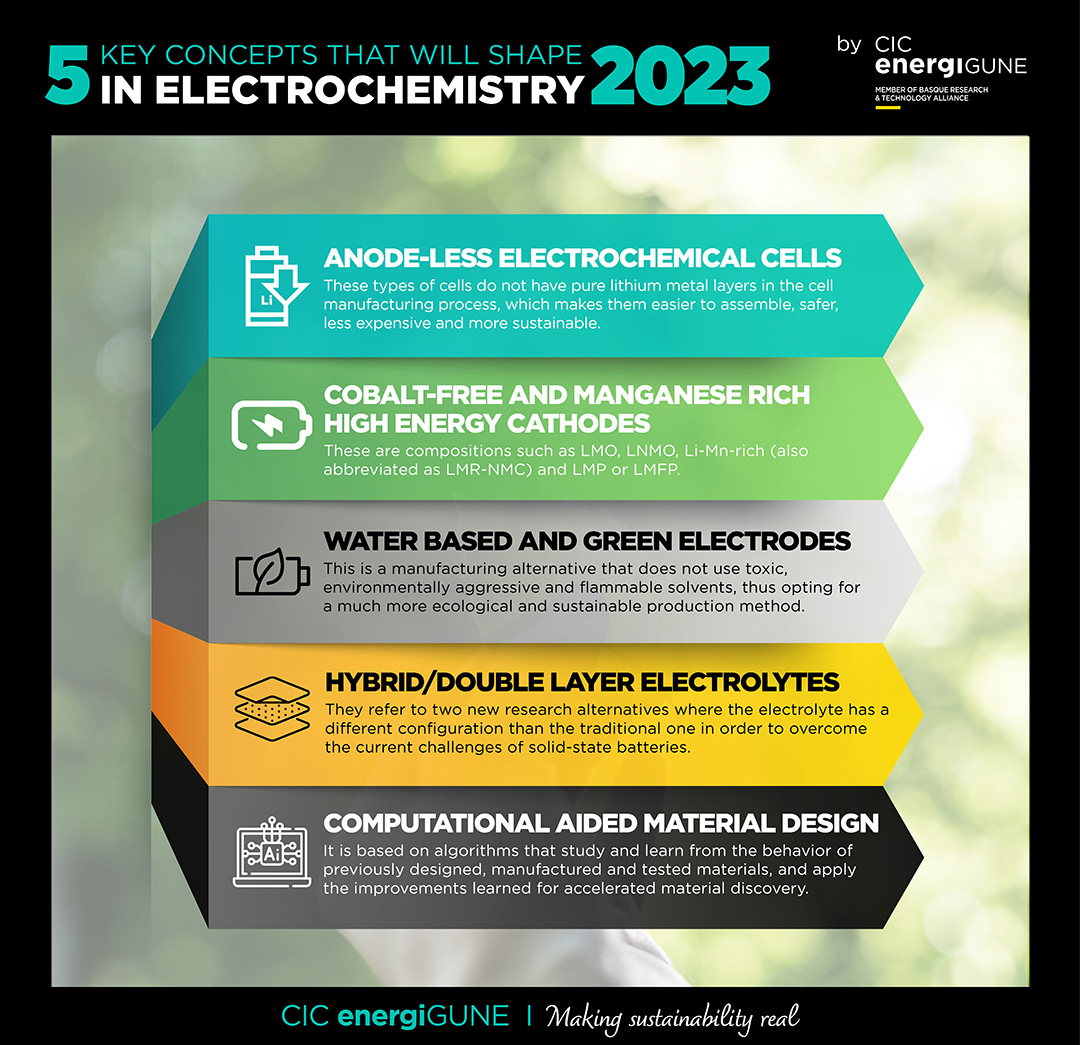

Anode-less electrochemical cells

The so-called anodeless batteries (specifically, without lithium metal anode) have attracted the attention of the battery industry due to the absence of pure lithium metal layers in the cell manufacturing process, which makes them easier to assemble, safer, less expensive and, of course, more sustainable.

However, one of the biggest challenges that the scientific community will face in 2023 is the reduction of efficiency in these devices due precisely to the deficiency of lithium in the device and the ultrathin layers and interfaces that act as anodes in these configurations.

At CIC energiGUNE we are already working on the development of protective coatings (ASEI), on the formation of stable interfaces, and on new solid electrolytes compatible with this technology. In other words, research aimed both at eliminating the reactivity of lithium metal and at making the deposition and growth of the different layers as homogeneous, compact and pure as possible.

Cobalt-free and manganese rich high energy cathodes

Until now, cobalt has been considered a key element in the manufacture of batteries, especially due to the electric vehicle boom. Moreover, according to a study by the Cobalt Institute in 2021, 34% of the cobalt extracted was destined for electric vehicles, to which should be added 31% destined for batteries for other types of devices.

However, 50-60% of the world´s cobalt resources are located in politically unstable countries and are extracted under questionable working conditions. In fact, the European Commission already identified it in 2017 as a critical raw material on which it wanted to reduce its dependence. Hence, cobalt-free lithium-ion cathodes are key to the future generation of electric vehicle batteries.

However, reducing this critical raw material in cathodes without compromising energy and power performance is one of the biggest challenges for the scientific community. Hence, alternatives are being sought to compensate for the lack of cobalt with some other promising material that delivers the same performance.

One of the options that we will hear most about in 2023 are cathodes -without cobalt- with a high manganese content. We are talking about compositions such as LMO (lithium manganese oxide), LNMO (lithium nickel manganese oxide), Li-Mn-rich (also abbreviated as LMR-NMC) and LMP (lithium manganese phosphate) or LMFP (lithium manganese iron phosphate).

Among them, high voltage spinel LMNO, on which CIC energiGUNE is working in projects such as CoFBAT, 3believe, HighSpin and Nextcell, stands out as a promising alternative.

Throughout 2023 we will see how research efforts will focus on accelerating their commercialization, in order to take these more sustainable batteries from the laboratory to real applications.