350-400 Wh/kg Li-S prototyping pouch cells have been demonstrated in literature, although cycle life is still limited to less than 100 cycles. To meet application requirements, improving cell stability and cycle life are imperatively needed.

In such content, LISA project was born with the aim to deliver 20 Ah Li-S pouch cells with high gravimetric energy of 450 Wh/kg and volumetric energy density of 700 Wh/L, safety and stability for at least 1000 cycles. Additionally, the fabrication of proof-of-concept 3 Ah 21700 cylindrical cells was also targeted, to cover the demand of smaller cell formats with similar performances than the larger pouch cells.

To achieve such ambitious targets, a strong multidisciplinary consortium was built, including CIC energiGUNE, with 13 partners from 6 different European countries, such as Fraunhofer IWS, Varta Microbattery, Renault or VDL, and the Spanish institution LEITAT.

12 work packages (WP) were designed, covering all relevant aspects of the Li-S battery. Lithium metal anode stability, high loading cathode development and novel strategies for high performing stand-alone electrolyte systems are core tasks of the project.

CIC energiGUNE’s role in LISA

In this context, CIC energiGUNE plays a pivotal role leading the WP devoted to the development of a stand-alone dielectric as solid-state electrolyte for high performing Li-S cells, a key component of LISA cell concept.

The WP aims at the integration of a thin solid Li-ion conducting film in the final Li-S cells, to limit the amount of liquid electrolyte needed and increasing the energy density of the system. Moreover, this film can also act as protective layer against the growth of lithium dendrites, one of the most important challenges of this technology to achieve long cycling life of Li-S cells.

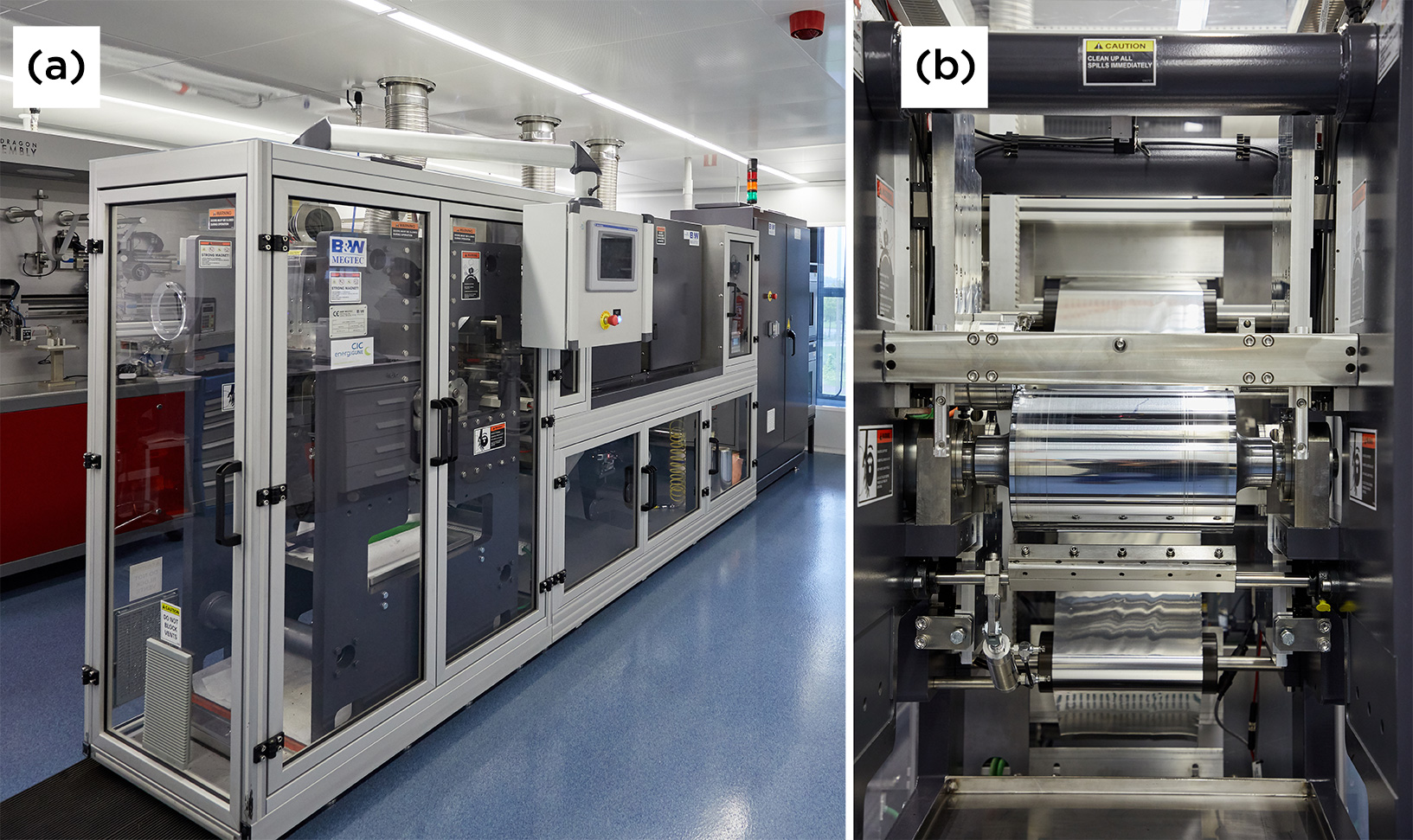

Together with the French partner Arkema, who provided the raw materials of the solid electrolyte, and thanks to CIC energiGUNE’s Prototyping line with dry room facilities and roll-to-roll comma bar equipment, we were able to fabricate > 100 m of thin electrolyte coating, to be used in the assembly of the final Li-S pouch cells (Figure 1). Indeed, the upscaling of the electrolyte coating production represents one of the most important critical steps accomplished in the project.